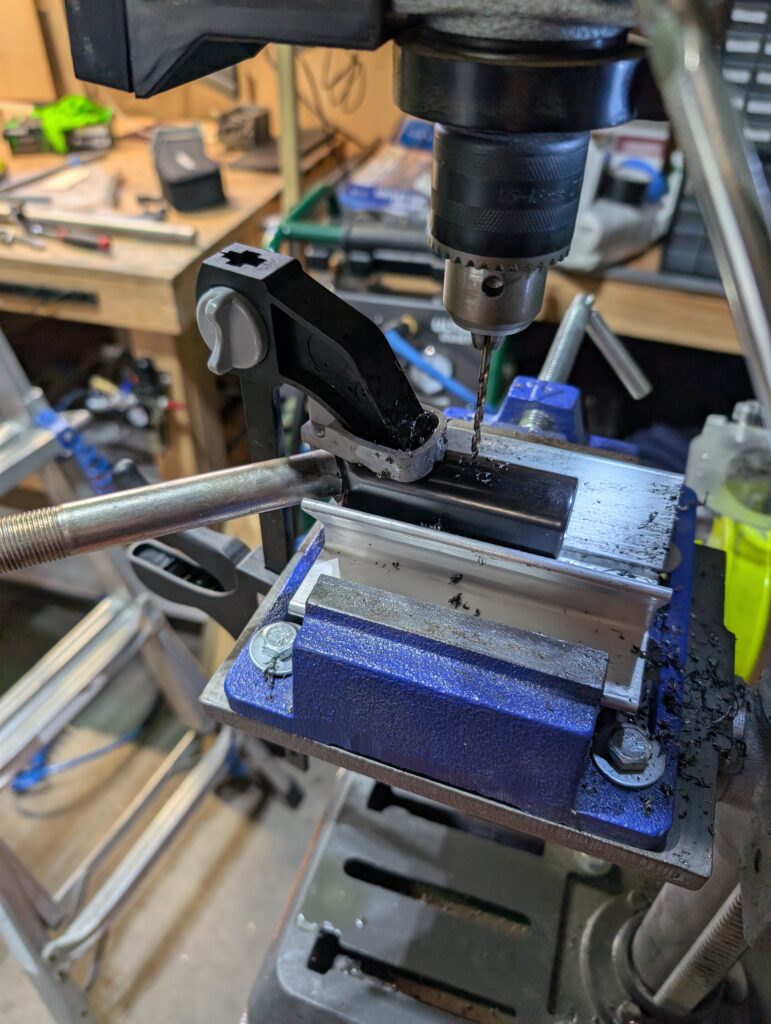

Drilled motor mount hole in new RH gear leg same as previous but used V block in drill press to ensure squareness. Deburred hole and attached new RH gear leg to fuselage with AN4-30A bolt. Drilled 1/8″ pilot hole through new RH axle (one side only). Setup axle toe-in jig by clamping aluminum angle to the front of each axle with toe-in spacers and 1/4″ of steel spacers. Leveled fuselage then setup laser level to project axle height. Leveled axles then clamped both axles to angle to establish toe-in on gear. Starting on the LH axle, clamped V block drill guide to axle housing then pilot drilled axle and gear leg with 1/8″ cobalt bit. Upsized to 3/16″ then temporarily held assembly together with AN3 hardware. Moved to RH side and repeated same procedure stopping multiple times to ensure rig had not moved. After verifying fit, final drilled RH then LH axles and gear legs to 1/4″. Deburred all holes then installed axles with AN4 hardware and marked with torque seal. Verified toe in one more time before removing jigs.

Hours Worked: 4.64

Leave a Reply