Circuit Breaker Wiring – Part 1

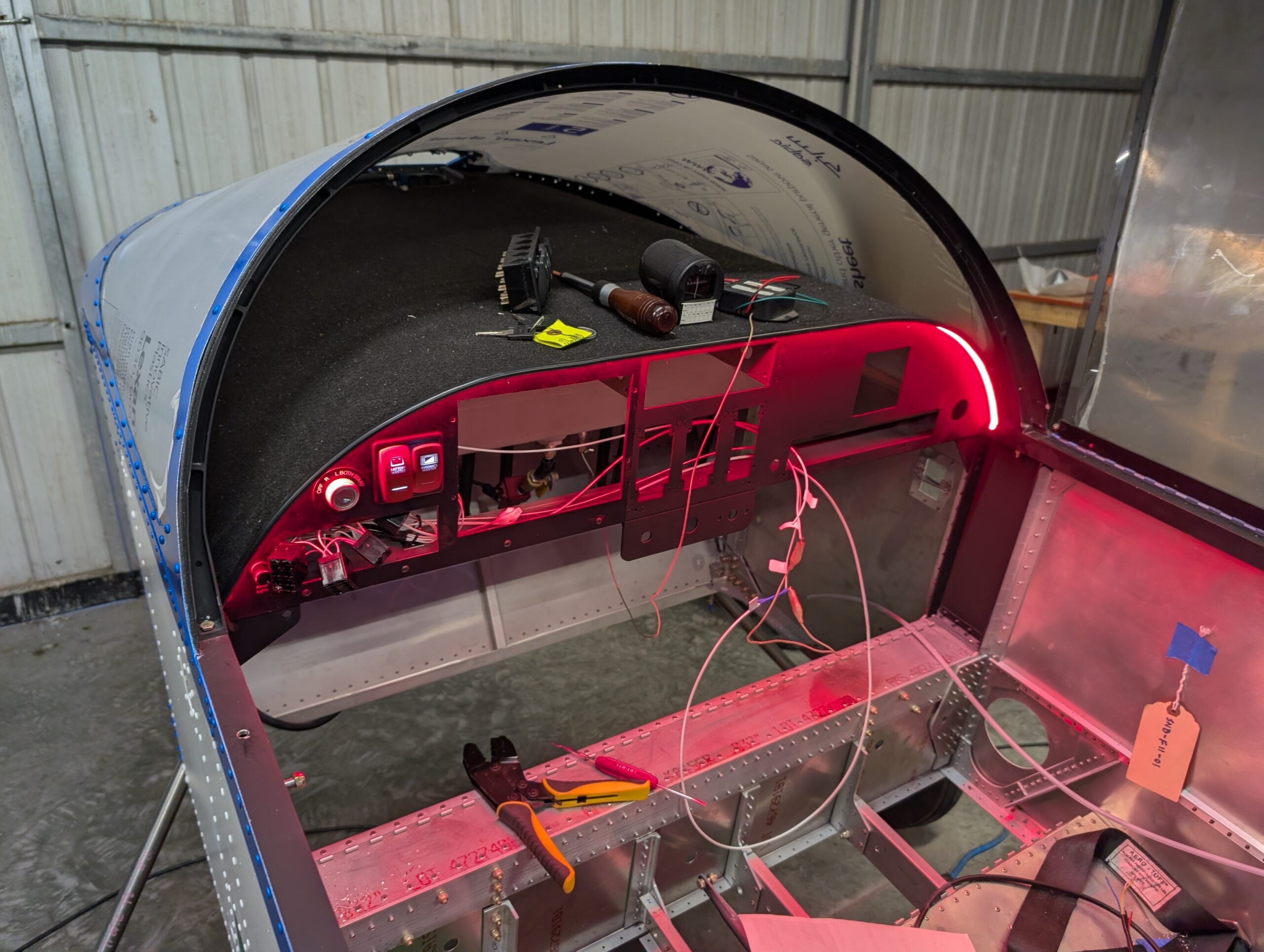

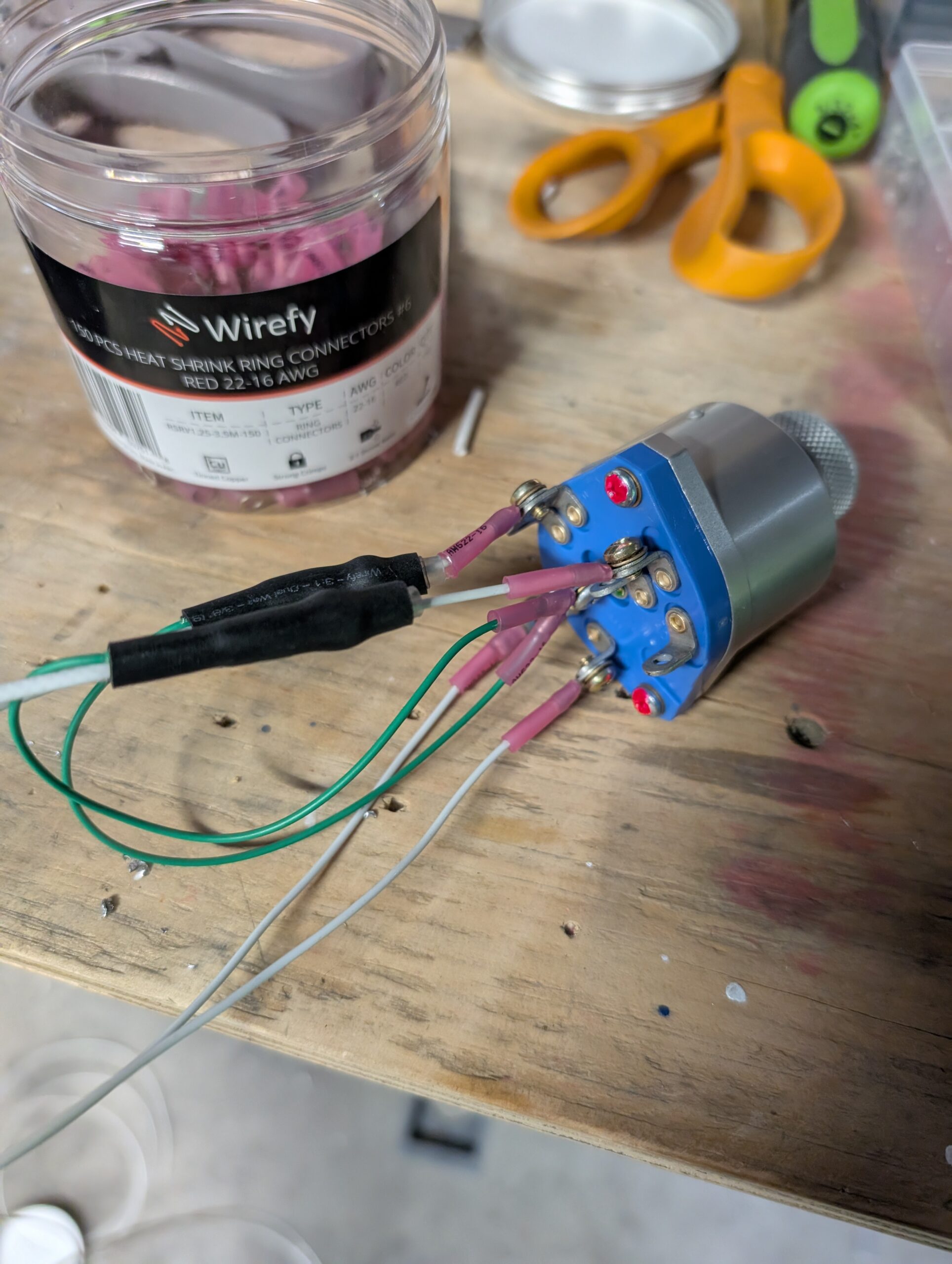

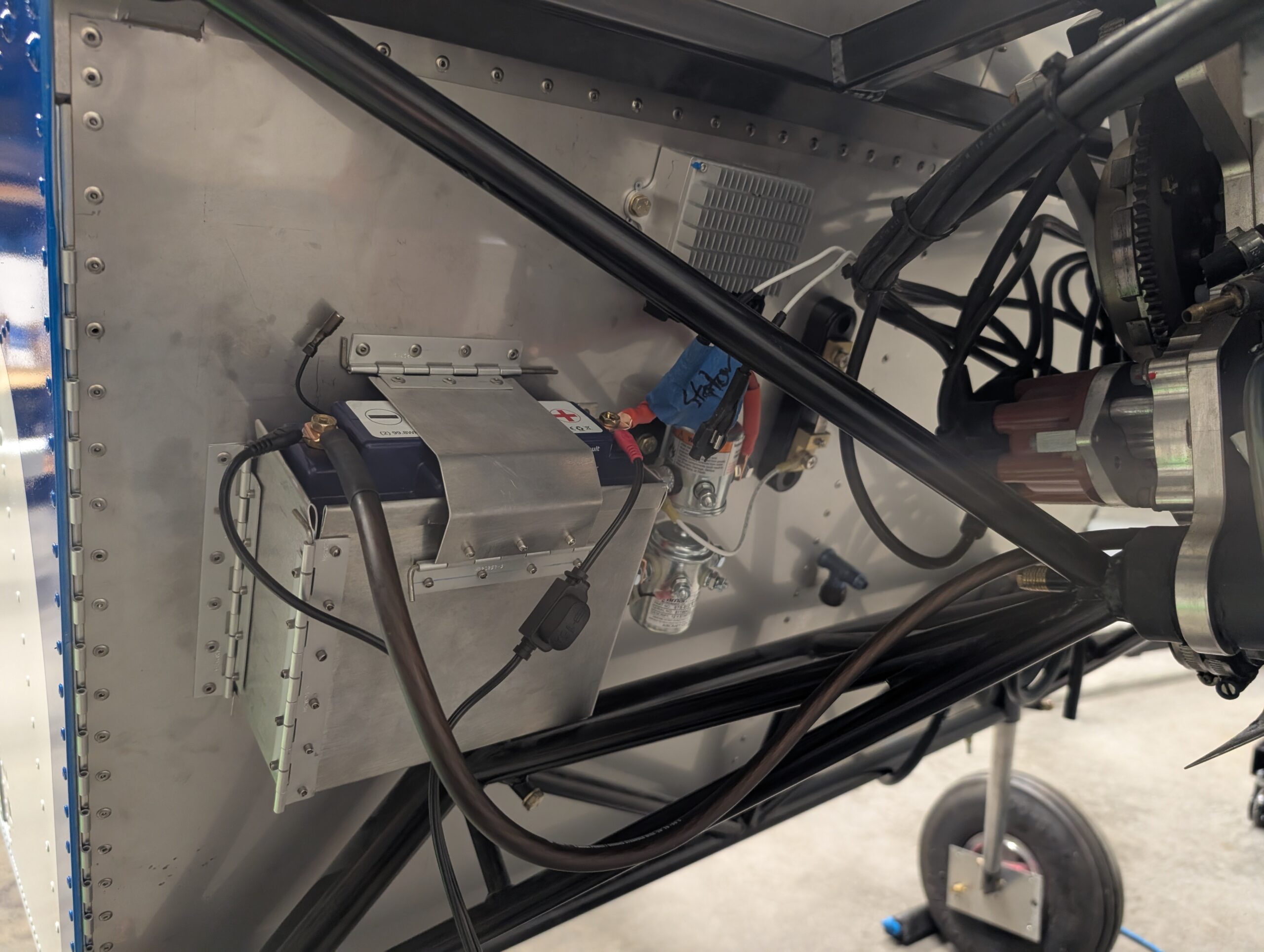

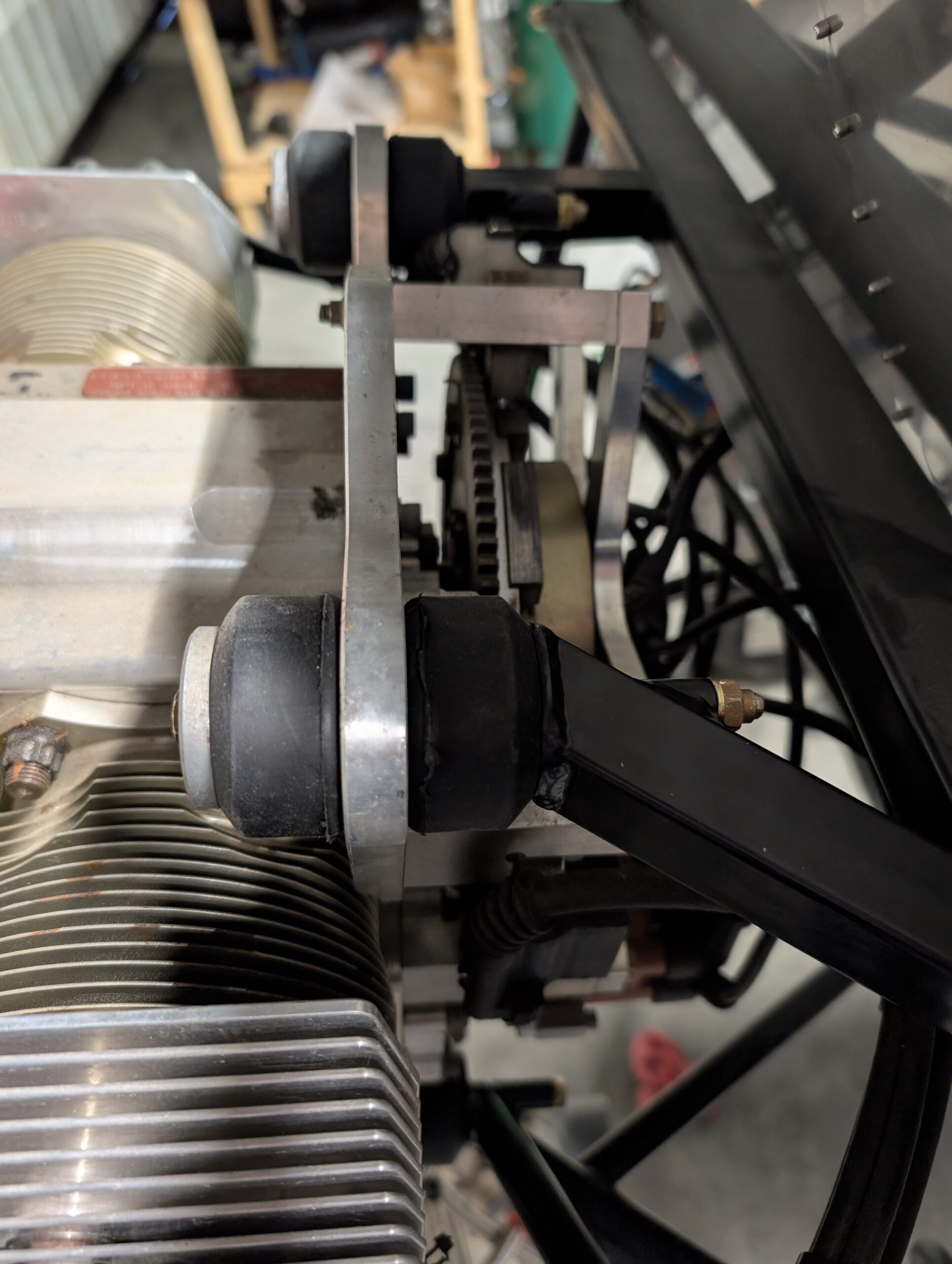

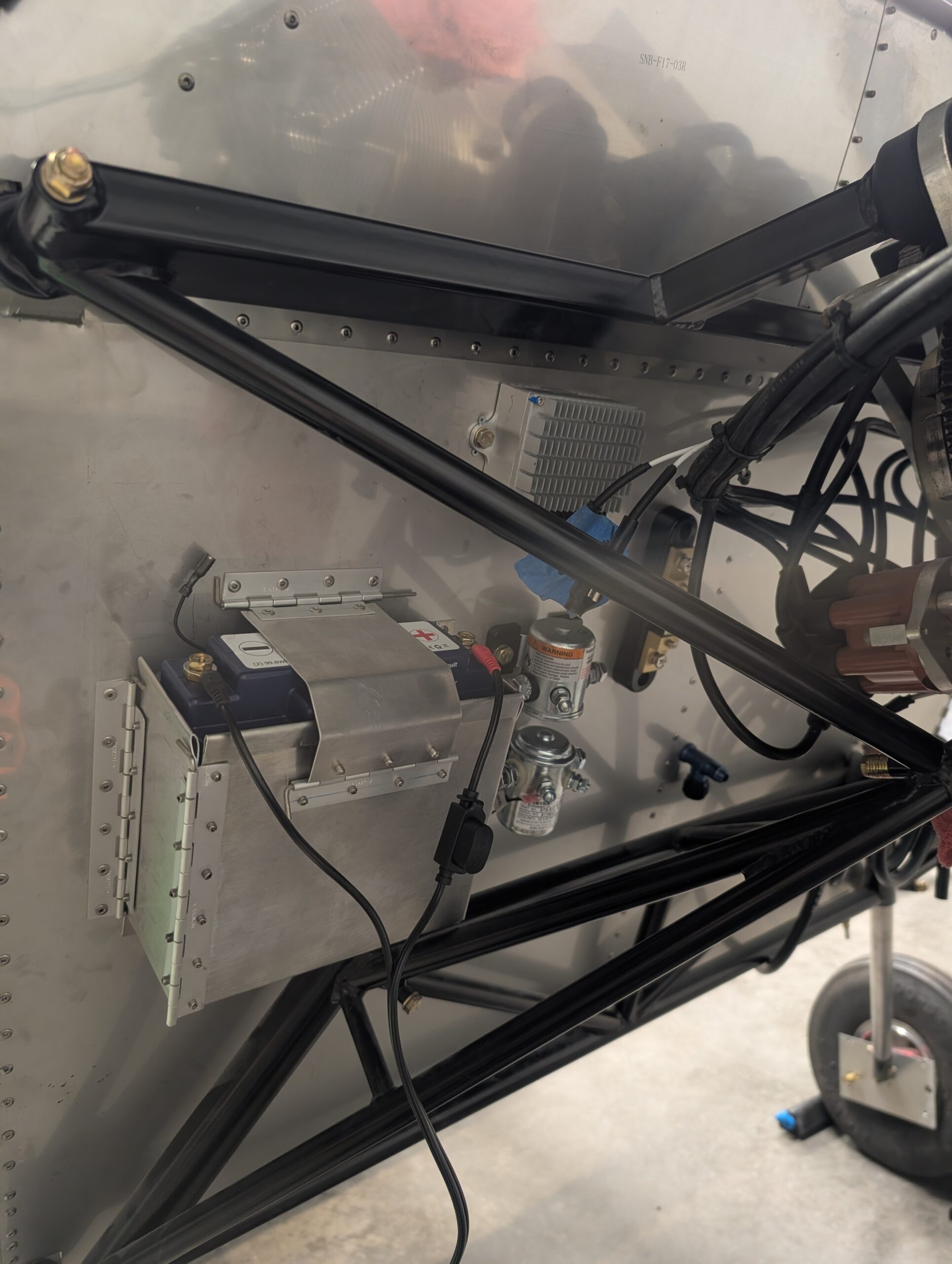

Began terminating panel wires to RH panel cover and circuit breakers. Connected master relay, master switch, and avionics switch wires to bus bars then connected available components to top of circuit breakers. Screwed RH panel cover into place onto panel…