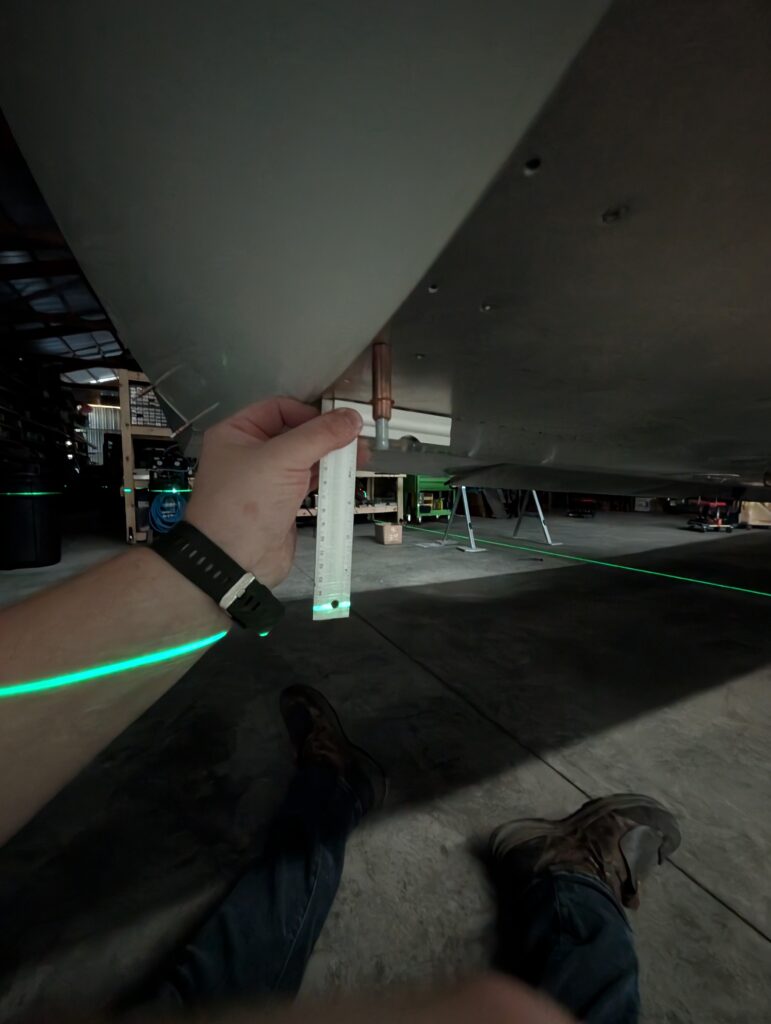

Began wing rigging process by inserting RH wing into spar box then inserting LH wing. Supported wing tips with saw horses while trying to align the three rigging holes between the two spars. Process went much easier with three people: one on each wing tip and one person inserting bolts. After bolts were inserted into the rigging holes, stacked washers on bolts and tightened spars together. Adjusted wings to be centered on fuselage then placed spar bumpers below spars onto lower longerons. Used laser level to level wing tips based on laser plane; measured from bottom of spar at wing tips. Set wing incidence angle by using clamps on rear spar to set them at plans dimensions. Temporarily installed rear spar carry-through with AN3 hardware. Finally checked wing squareness to fuselage by measuring tip to tail; squareness verified with 3/16″ difference in measurements due to spar overlap. Clamped spars to rear tunnel web and followed plan instructions to first drill rear wing angles to 3/8″ with drill guide then updrill to 1/2″. Inserted bolts partway through from rear then reinstalled forward tunnel zee and wing attach angles. Will drill forward wing attach angles tomorrow.

Hours Worked: 4.43

Leave a Reply