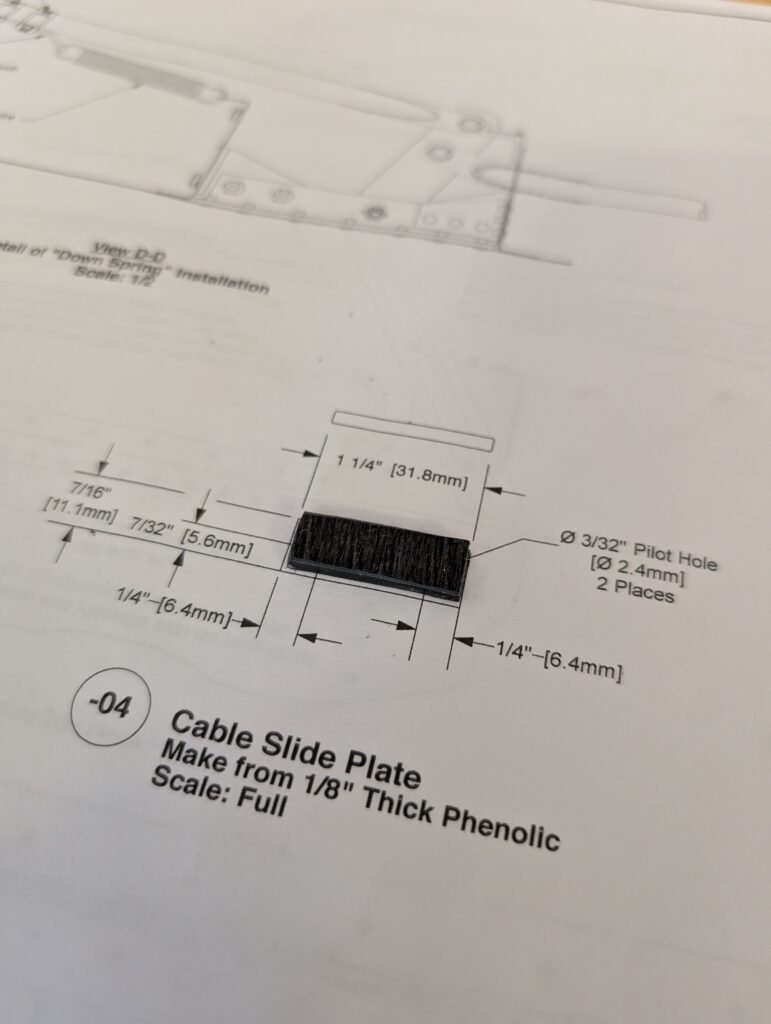

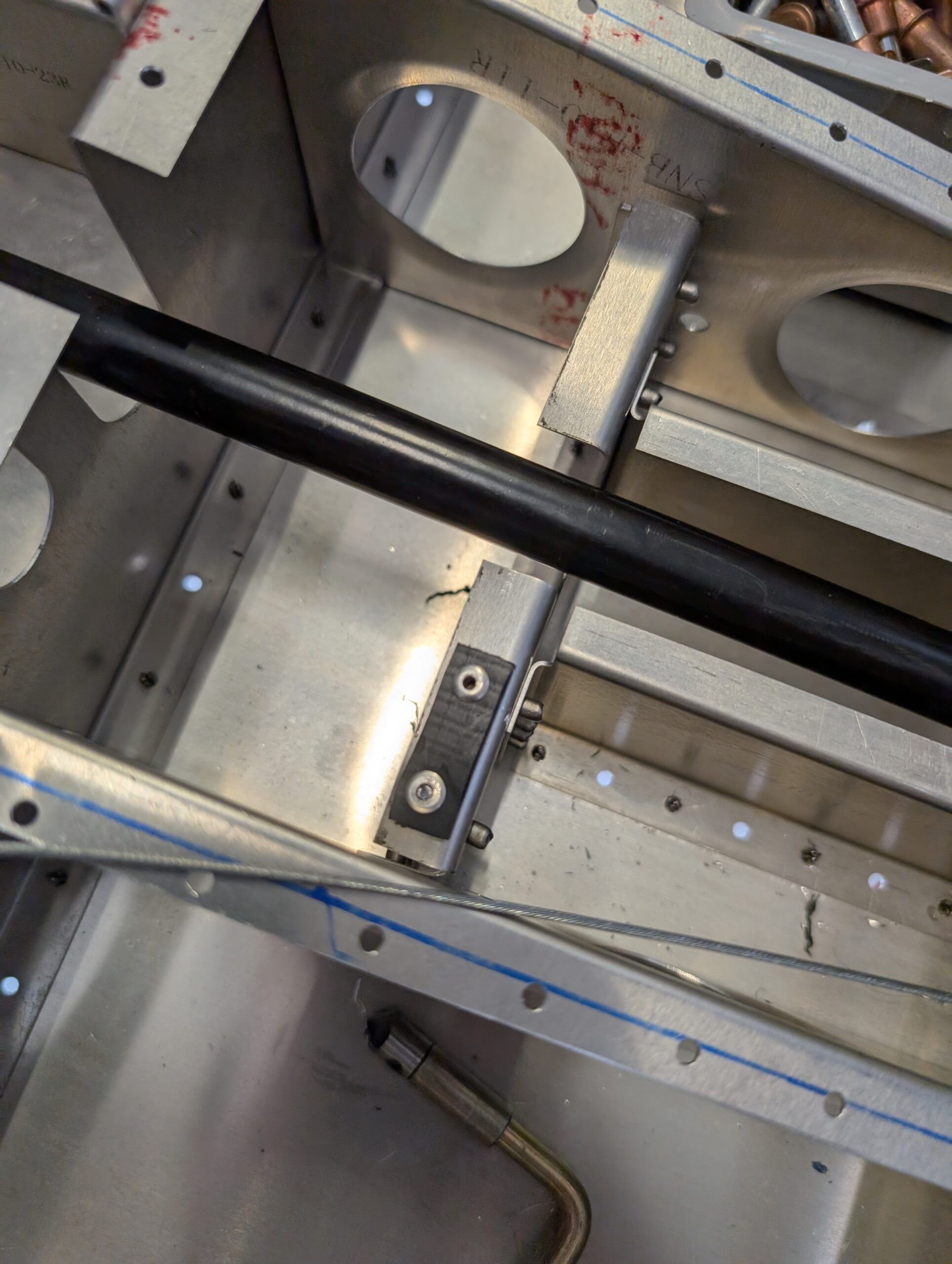

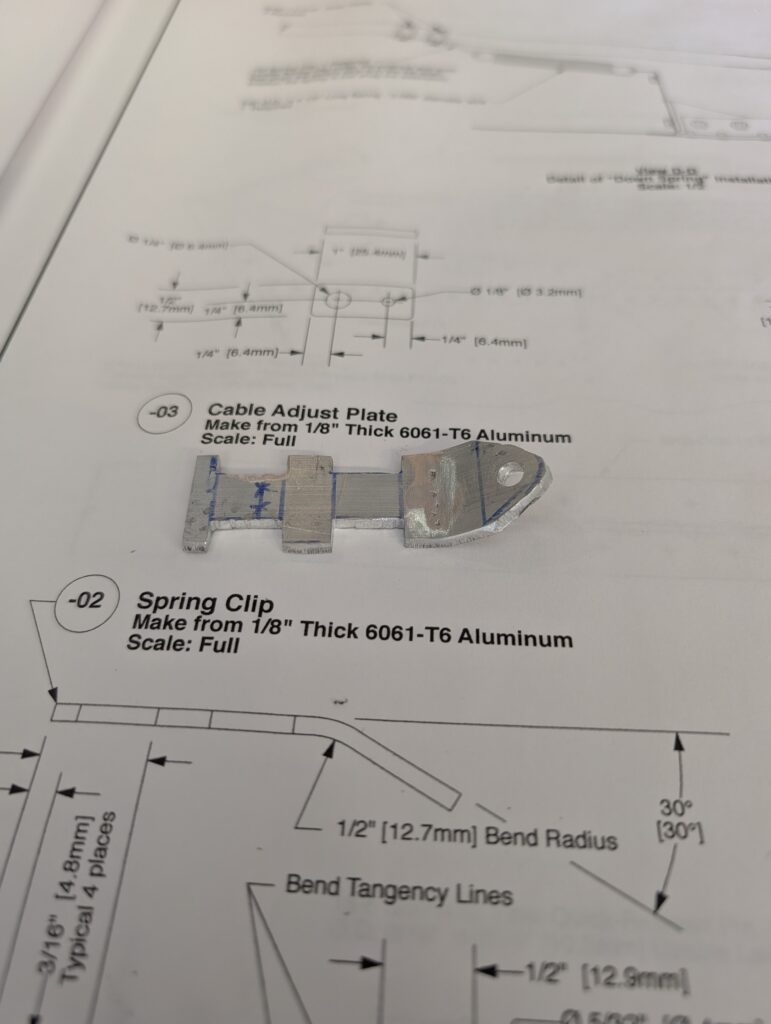

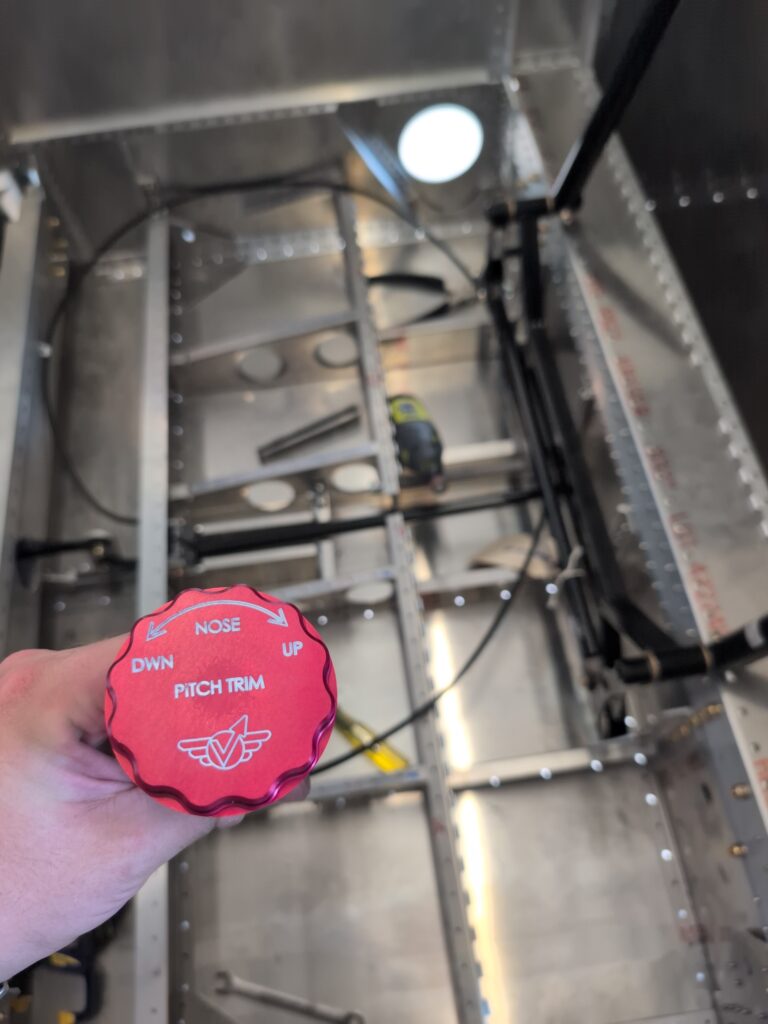

Began trim system installation by removing lower instrument panel and drilling holes for throttle, mixture, and trim wheel. Measured and drilled hole for trim cable sleeve below seat pan. Mocked up cable run and trimmed around 18″ from cable and sleeve. Ran cable through trim adjuster and sleeve then secured to rear spar carry through with D3 clamp. Cut trim cable wear surface from leftover spar bumper material then riveted on top of seat belt center channel. Created cable link from aluminum scrap then installed onto end of cable. Connected spring to control stick frame and adjusted cable so that spring is lightly tensioned with stick fully forward and trim full nose down. Verified clearance of cable link through seat pan lightning holes. Cut rear spring attach plate from aluminum bar stock then bent tang in vice per plans. Drilled rear spring mount hole in top of rear spar carry through angle and clamped attach plate to elevator push rod per plans (balance spring in slight tension when control stick fully forward. Flap tube interfered with spring installation below the pushrod so rotated attach angle to top of push rod. Will need to add additional clamp before finishing trim system.

Hours Worked: 3.17

Leave a Reply