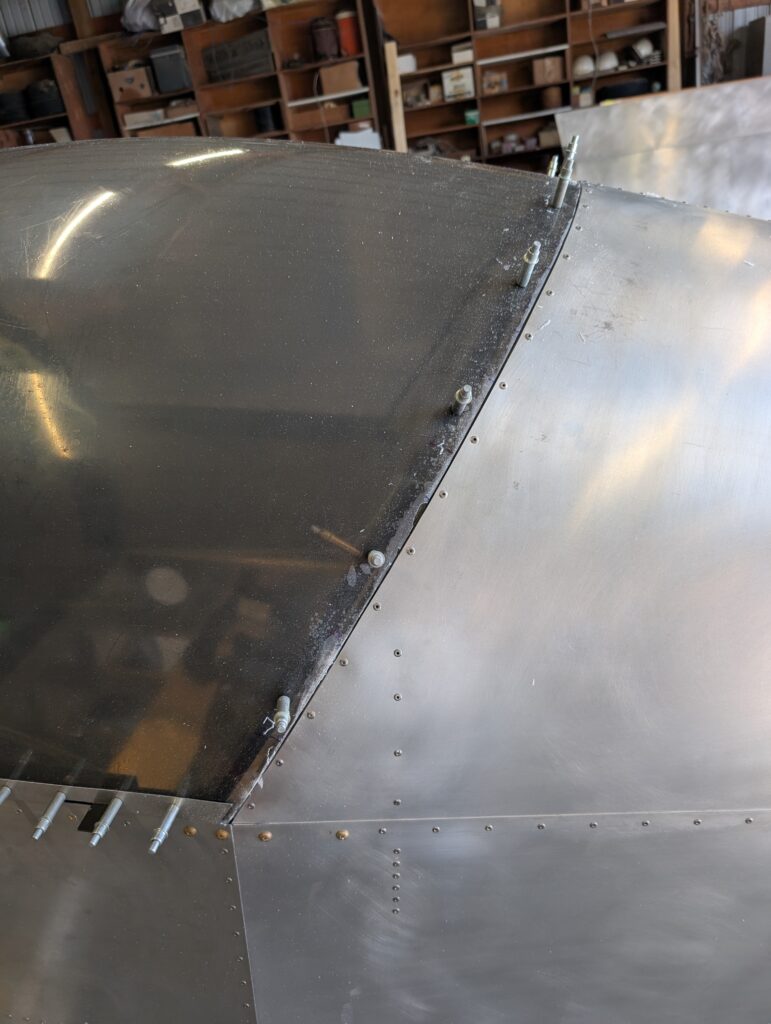

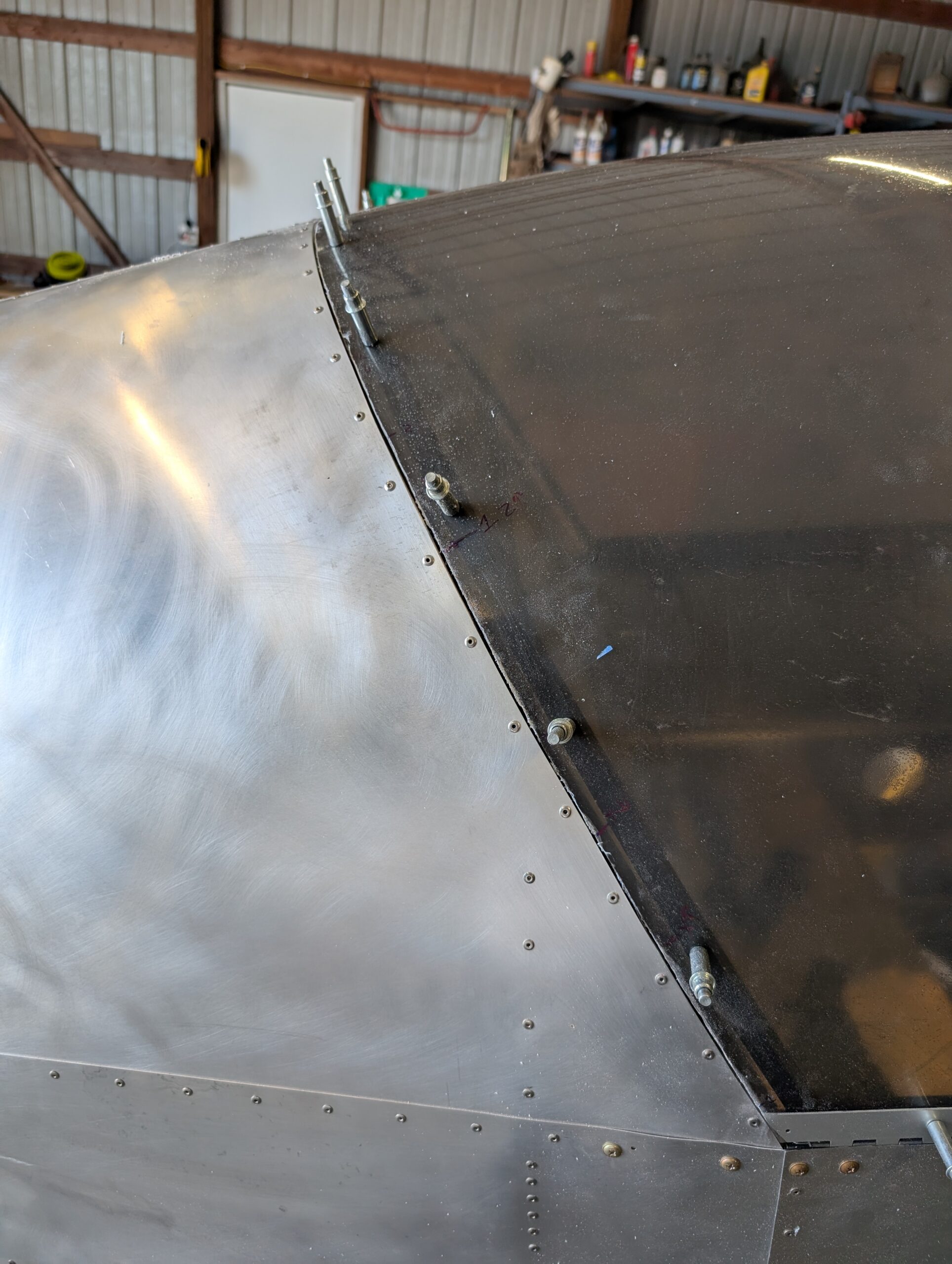

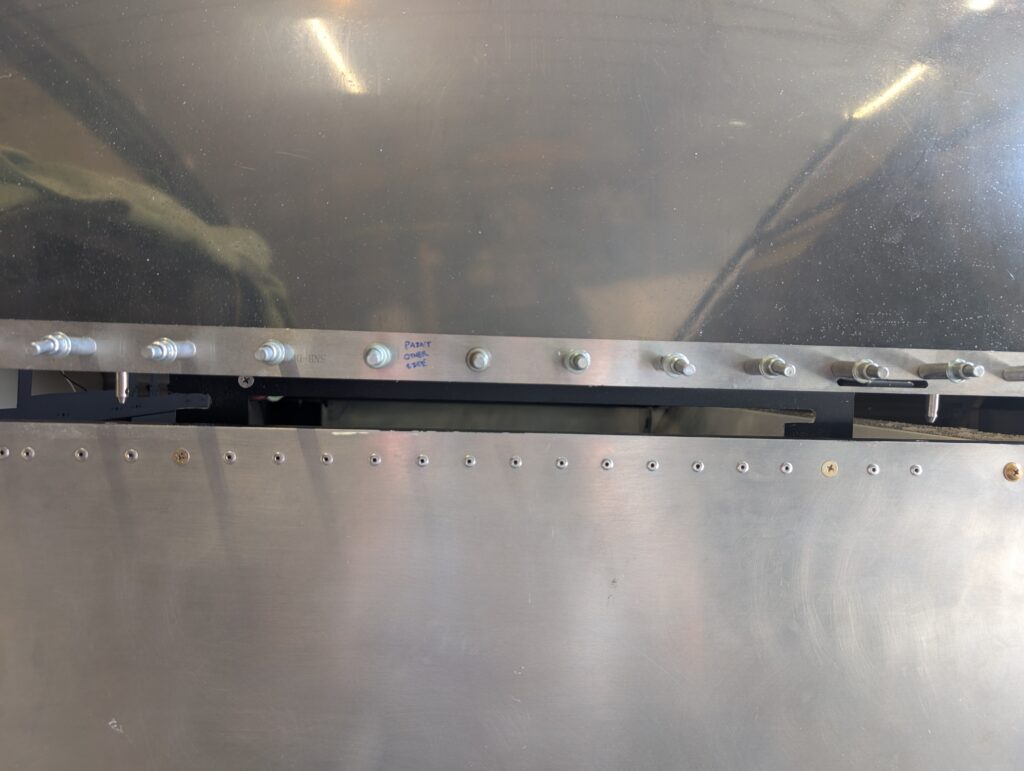

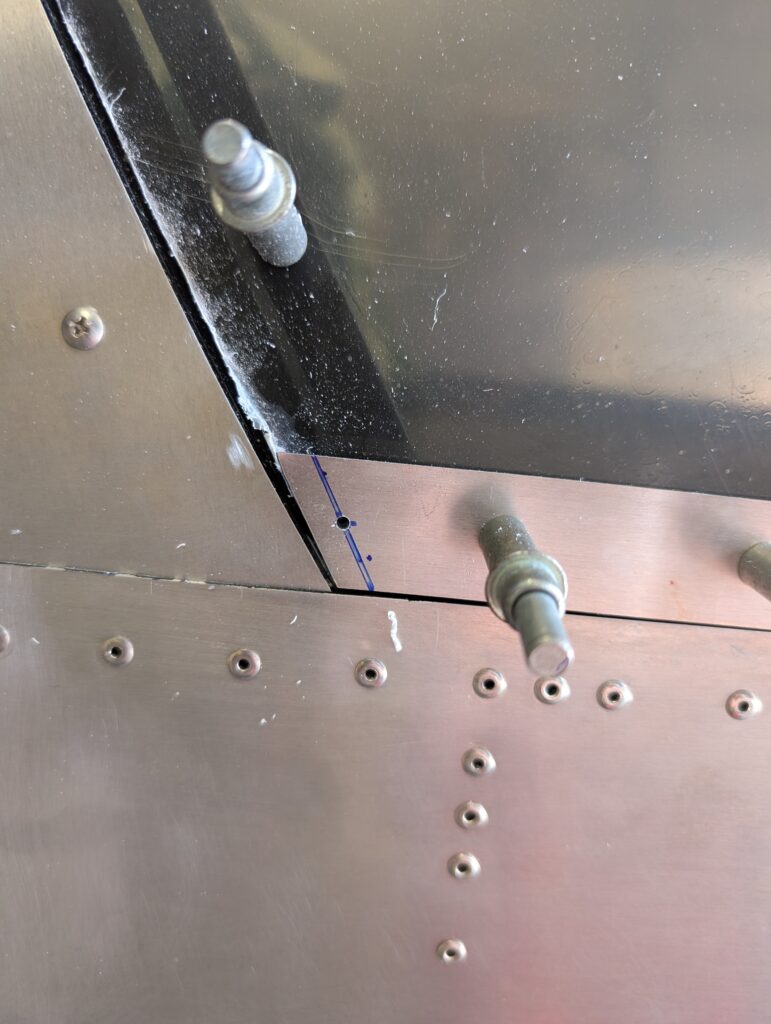

Updrilled canopy alignment holes in upper longeron with #F drill bit. Continued to trim, sand, and deburr canopy to achieve 1/16″ gap all around; finally achieved. Worked on latch mechanism by removing lower nylon washers to lower latch assembly slightly. Used a light coating of LPS-2 between canopy frame and latch to make it slide better. Using inspection camera, determined that a small amount of metal needed to be removed from the bottom side of the canopy latch upper slot to prevent binding. Reshaped latch slots using file until canopy latch mechanism worked smoothly. Finally latched canopy into place and verified fitment and gaps all around. Pilot drilled final end holes in LH side canopy trim. Removed canopy bubble and sanded all edges with 80 grit sandpaper followed by 220 grit. Once all rough spots were knocked down, deburred edges with metal deburring tool. Removed plastic from area around attach holes and updrilled canopy holes to 9/64″ using specialty plastic bit. Deburred holes then countersunk top side with hand deburring tool for countersunk washers, checking fitment along the way. After finishing prepping the canopy for final install, began tapping canopy frame holes for 6-32 screws. Broke tap off in first hole so will need to remove before moving on.

Hours Worked: 5.30

Leave a Reply