Controls

-

Rudder Control System – Part 2

Heated up C01-03 rudder spring stock with propane torch and bent springs to specs in plans. Previously tried to bend springs without heat and spring steel broke rather than bent. After installing springs into fuselage, discovered that plan dimensions were a little long and resulted in rudder pedals not returning to neutral. Shortened springs by…

-

Rudder Control System – Part 1

Installed rudder pedals and mount blocks into fuselage. Applied white lithium grease to rudder pedals before tightening rudder pedal mount blocks. Fed rudder cables through aft fuselage and temporarily installed AN23 clevis pins into rudder horn. Installed cable fairleads into fairlead blocks. Bolted cable adjusters onto rudder pedals and marked LH cable adjuster hole per…

-

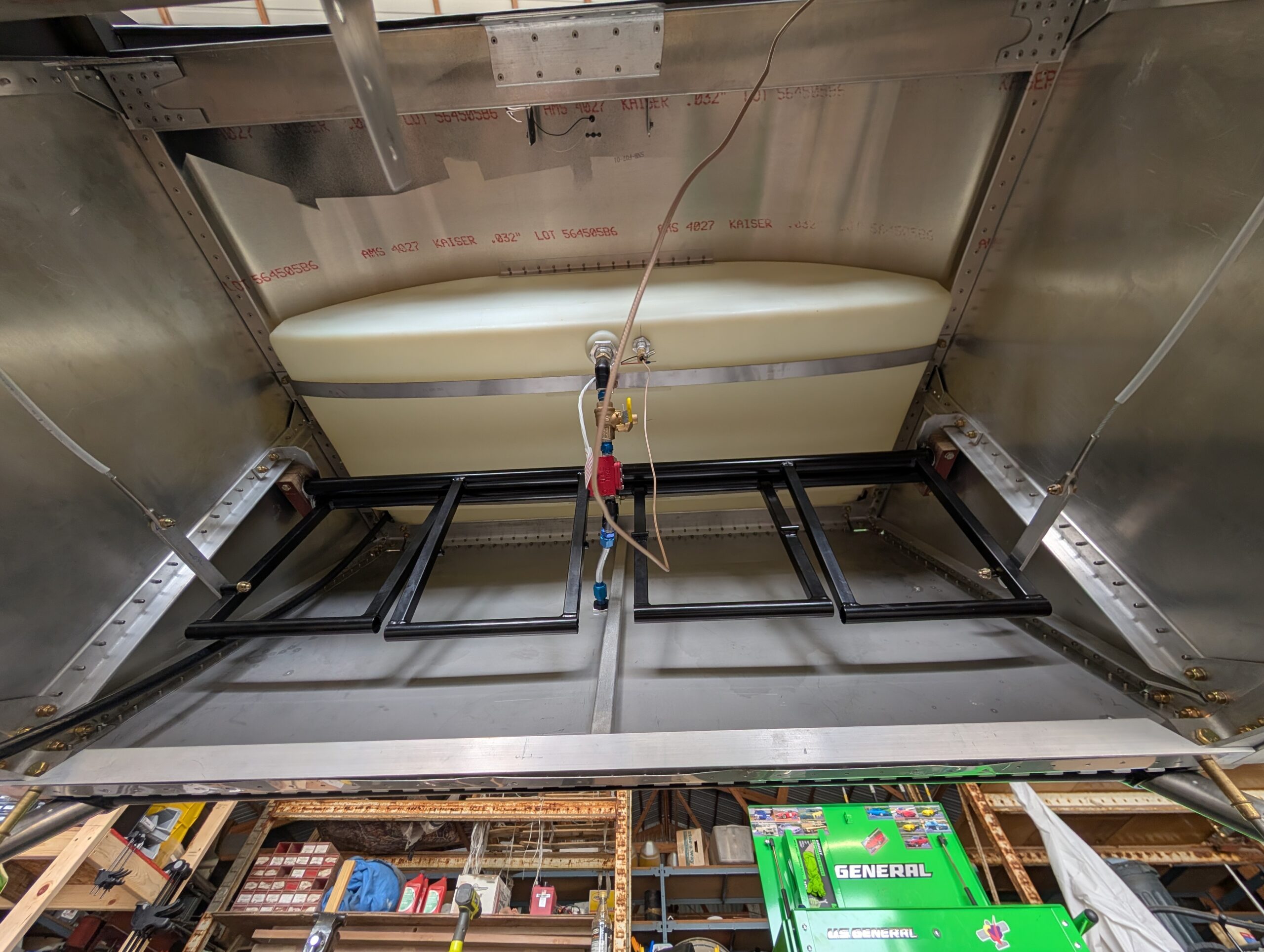

Trim System Installation – Part 2

Finished trim system by installing last clamp on elevator pushrod and balance spring. Will wait to adjust until flight testing occurs. Also added torque seal to elevator push rod bolts. Hours Worked: 0.32

-

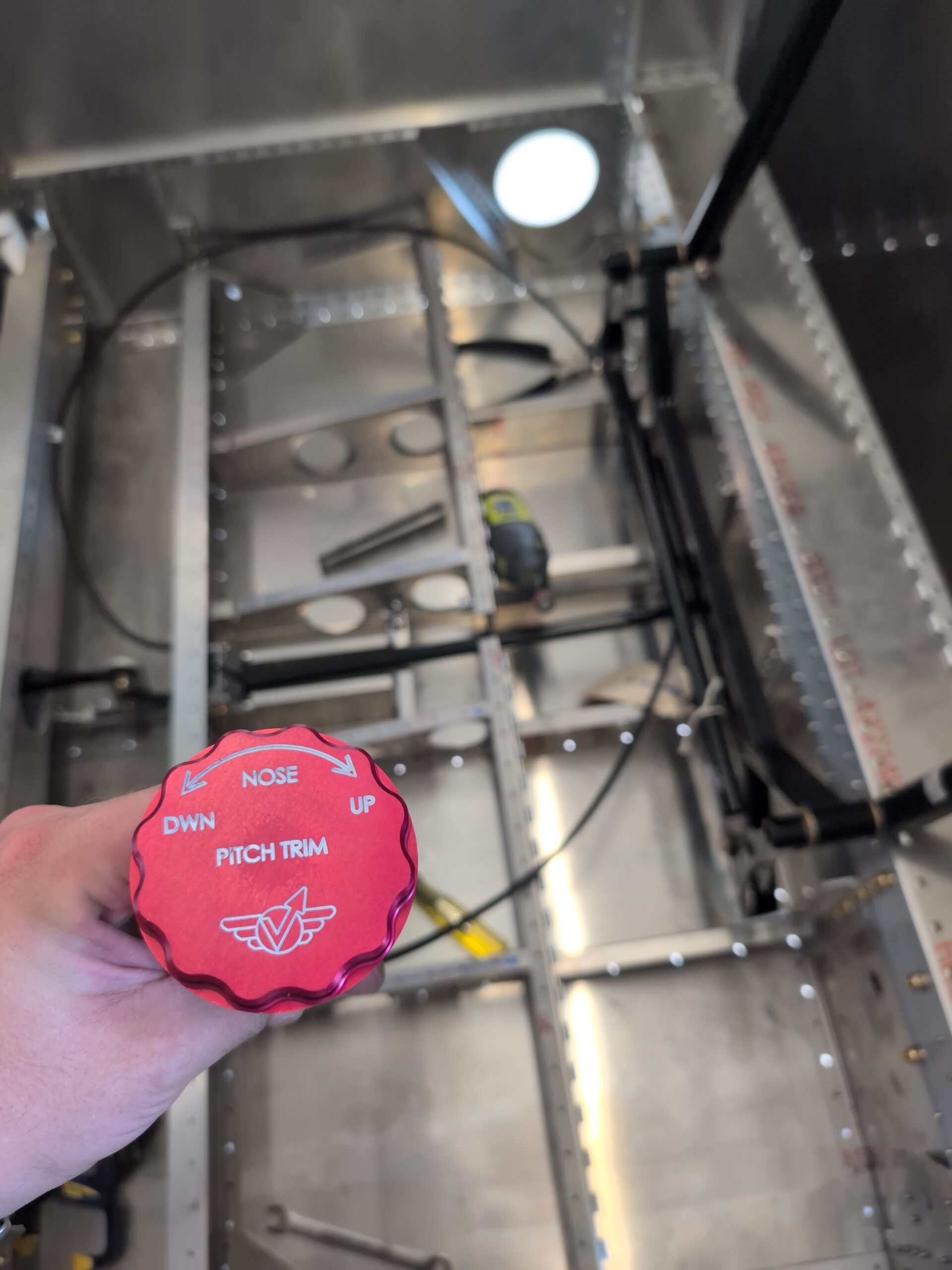

Trim System Installation – Part 1

Began trim system installation by removing lower instrument panel and drilling holes for throttle, mixture, and trim wheel. Measured and drilled hole for trim cable sleeve below seat pan. Mocked up cable run and trimmed around 18″ from cable and sleeve. Ran cable through trim adjuster and sleeve then secured to rear spar carry through…

-

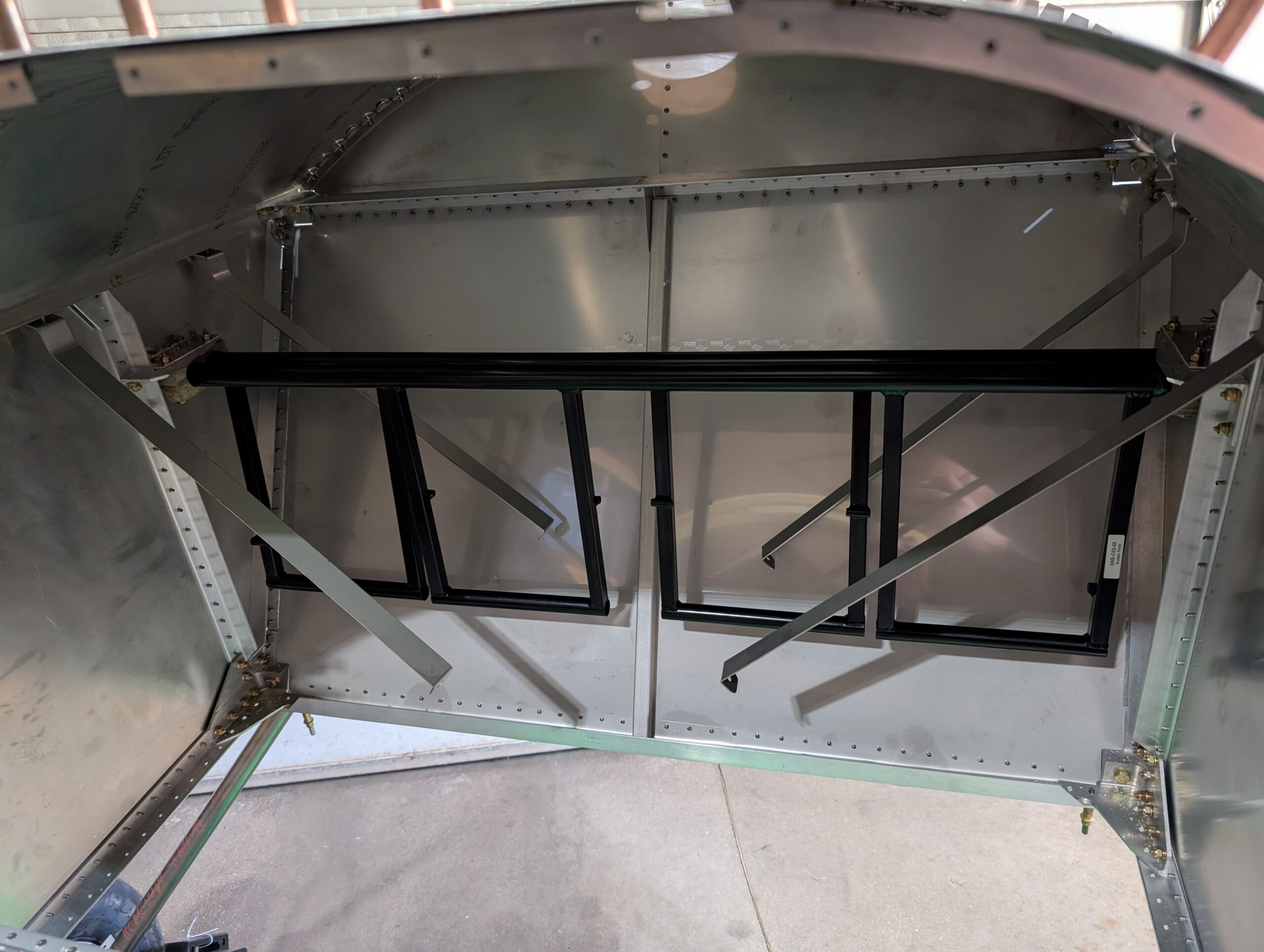

Elevator Control System – Part 1

Temporarily installed control stick assembly. Pressed SF-812-3 bushings into stick to idler bar and control frame then installed idler hardware permanently and stick hardware temporarily. Verified freedom of movement and clearances with idler bar. Pressed bushing into elevator push rod ends, clecoed forward pushrod support to cross ties, and checked clearance of elevator push rod.…

-

Control Stick Assembly – Part 3

Disassembled dual stick assembly and deburred stick holes. Lubricated control stick horns with lithium grease and deburred taper pin holes. Reassembled left and right control sticks and attached link rod with hardware. C04 complete! Hours Worked: 0.70

-

Control Stick Assembly – Part 2

Set bushings into top of control stick frame with Loctite 638. Using new taper reamer, reamed LH stick grip hole and inserted taper pin. Repeated whole process for right hand stick grip and found that sticks were not parallel with control horns and cross link tube would not fit in between left and right control…

-

Control Stick Assembly – Part 1

Began control stick assembly process by drilling 1/8″ pilot holes in bottom of stick grips. Removed powder coating from shaft of control stick horns by using heat, sandpaper, and scotchbrite wheel. Installed SF-2024-8 bushings into control stick frame; fit is okay but will need to put some Loctite 638 on bushings to ensure they do…

-

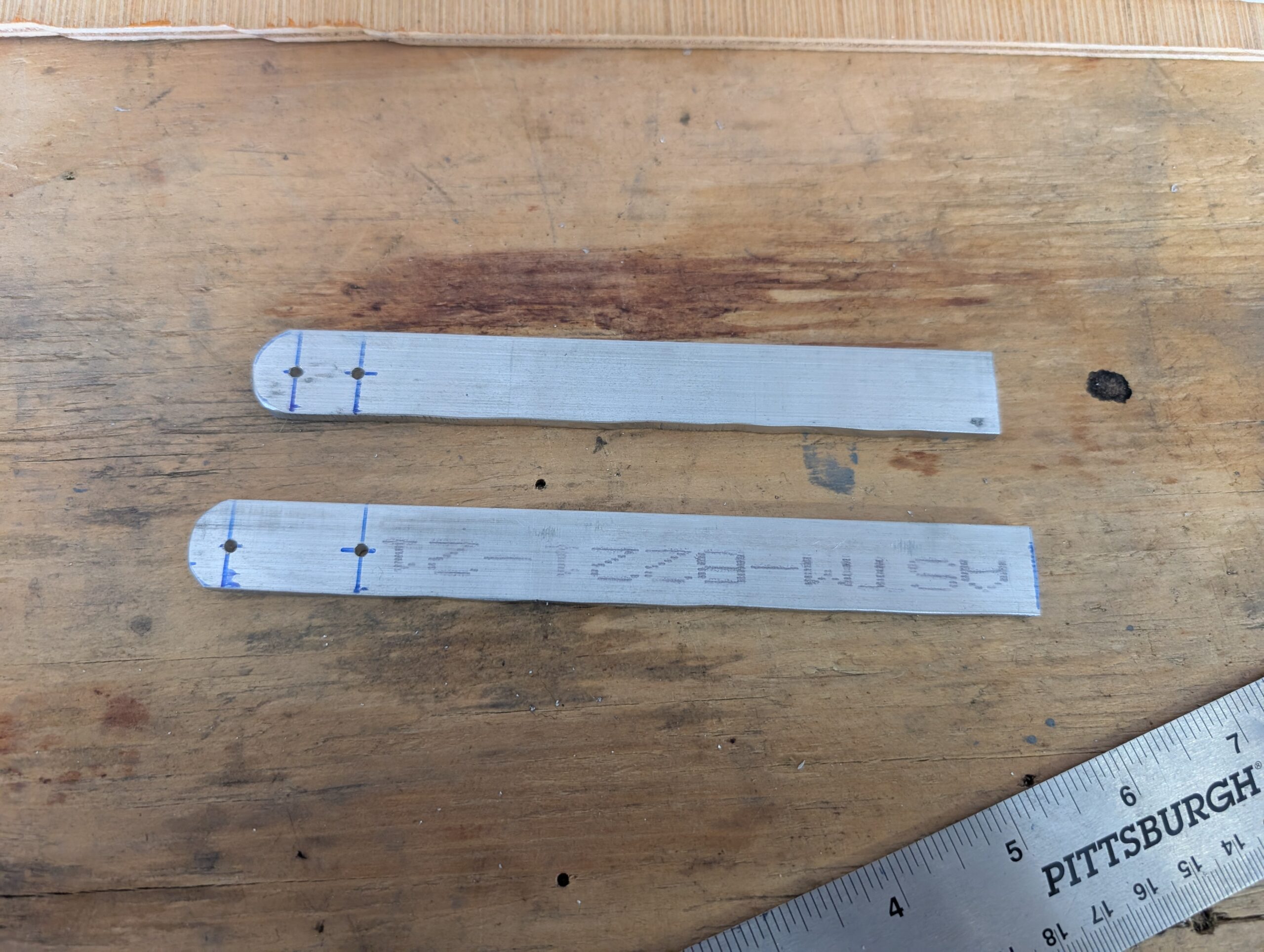

Control Pushrod Assemblies

Cut aileron tube stock to size per plans for dual-stick configuration. Marked and drilled holes for pushrod end fittings, then deburred and riveted -01 main aileron pushrod assemblies. Pressed spoiler bearings into rod end bearings using vice then installed onto main pushrod with jam nuts using dimensions given in plans. Drilled witness holes into female…

-

Rudder System Installation – Part 1

Located rudder pivot blocks onto fuselage and temporarily inserted rudder pedals to check fit. Fit and function seemed good so clamped blocks to fuselage and drilled forward mounting holes. Will need to remove assembly to apply grease in future. Hours Worked: 1.17

-

Rudder System Prep – Part 1

Cut rudder pedal pivot blocks from Phenolic sheet. Matched similar blocks together and rough sanded. Clamped blocks together then drilled mount holes with drill press. Temporarily bolted blocks together and sanded edges flat. Marked holes for rudder pedals then through drilled with Forstner bit. Deburred all holes and final sanded through holes. Hours Worked: 1.67