Fuselage

-

Fuselage Box Assembly – Part 10

Riveted upper cross tie #2 to vertical channels and upper cross tie box to vertical channels #1. Fit cross tie splice plates to upper splice plates via AN3 bolt holes and riveted plates to cross tie box. F21 complete! Hours Worked: 0.67

-

Fuselage Box Assembly – Part 9

Continued final assembly of tail cone. Started by clecoing lower cross ties and aft angle. Riveted aft angle and lower cross tie #5 in order to install aft Shear Web Assembly. Riveted shear web to aft bulkhead and lower aft angle. Un clecoed upper longerons to slip in shear Web Assembly and clecoed into place.…

-

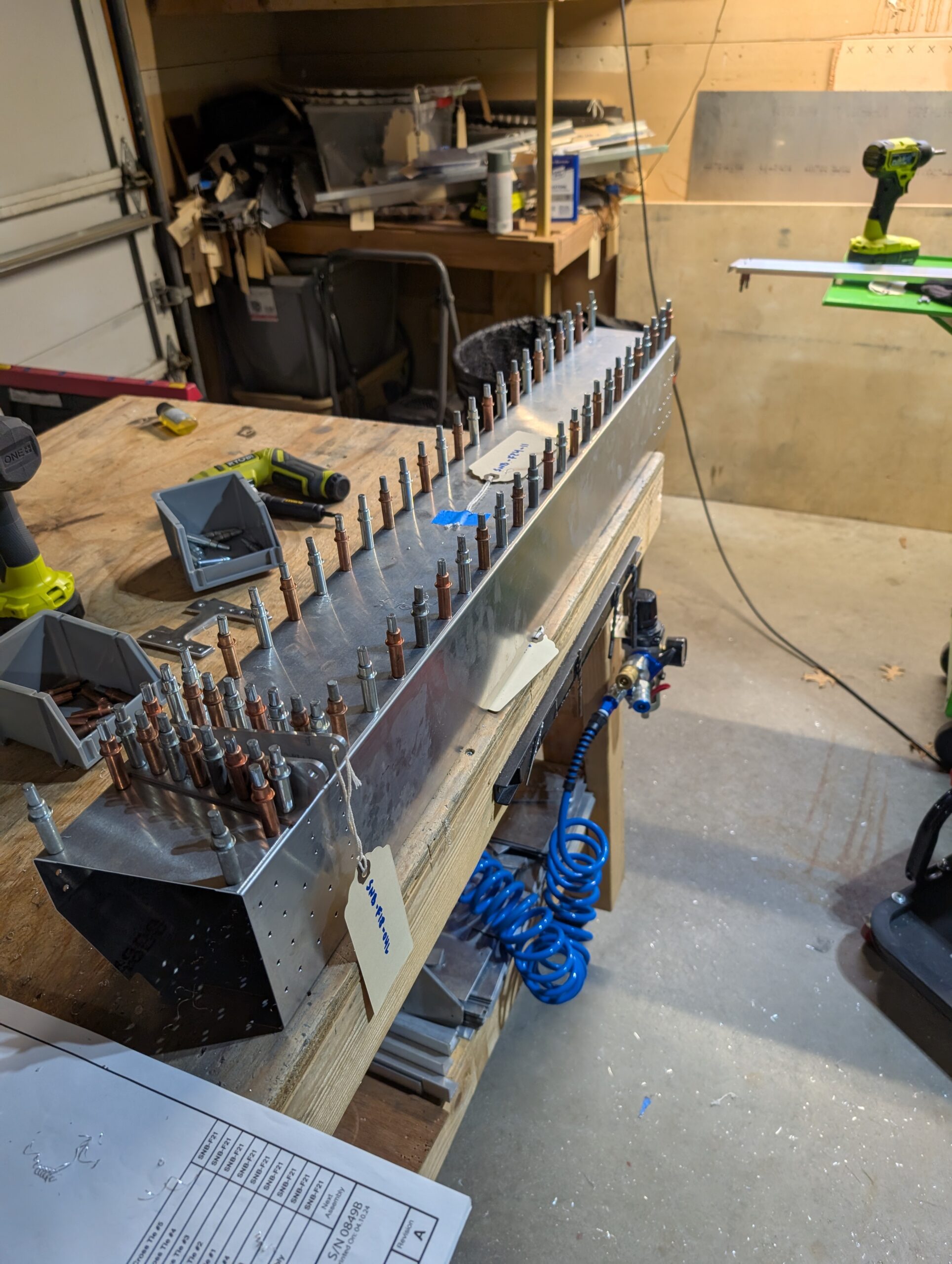

Aft Fuselage Part Prep – Part 5

Up drilled crosstie box cover and crosstie box. Also up drilled flap motor mount holes on bottom of crosstie box cover plate. Left flap drive mount holes on back of crosstie at 3/32″ as they will not be used. Hours Worked: 1.05

-

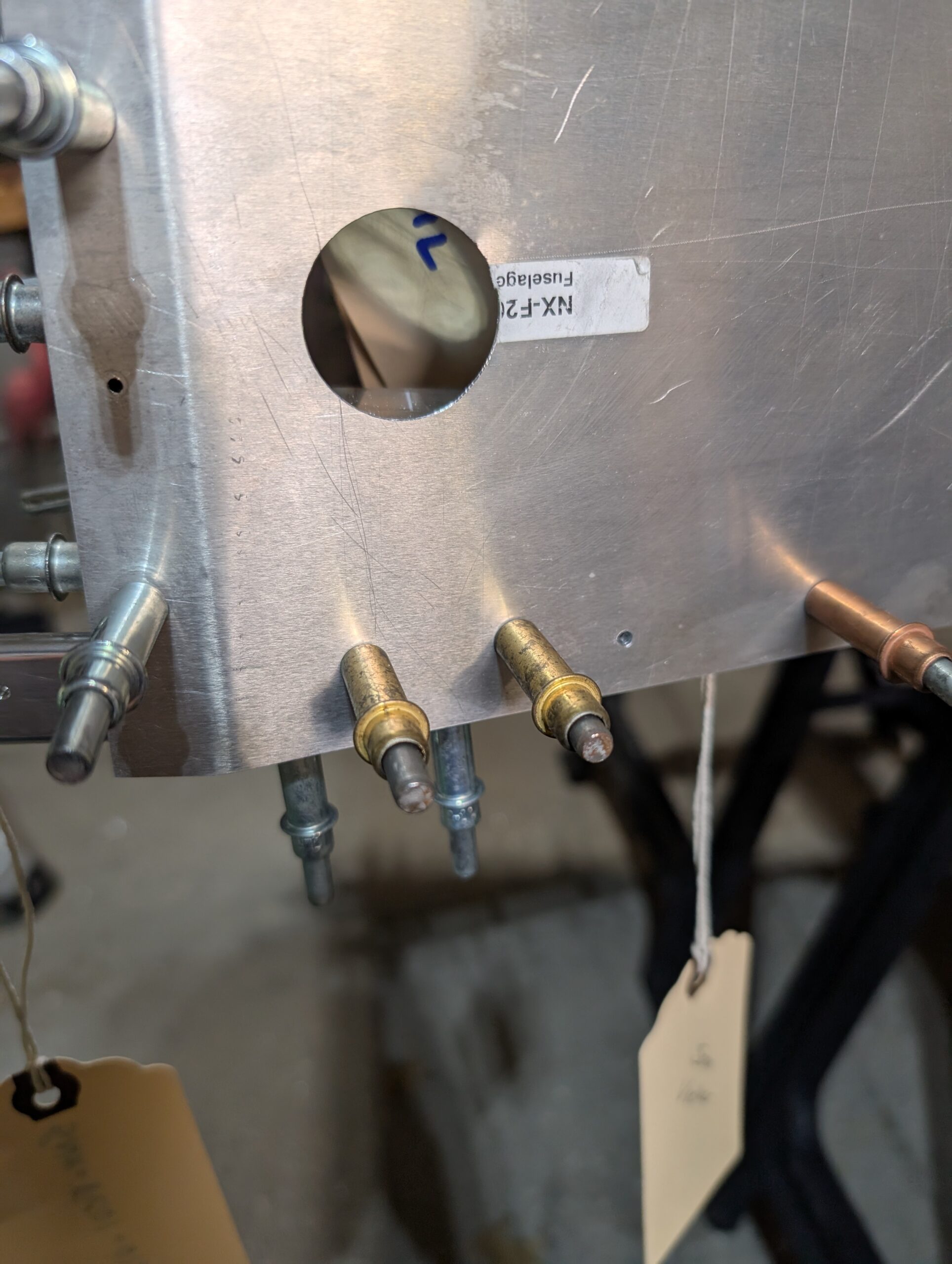

Aft Fuselage Side Panel Assembly – Part 5

Began final assembly of side panels by deburring, scotchbriting and cleaning all F25 parts. Started by riveting rudder cable fairlead mount blocks to vertical channels #1 and #5. Riveted lower longerons to aft fuselage side skins along with vertical channels #2-#5. Left vertical channel #1 just clecoed for now. Left top row of rivets on…

-

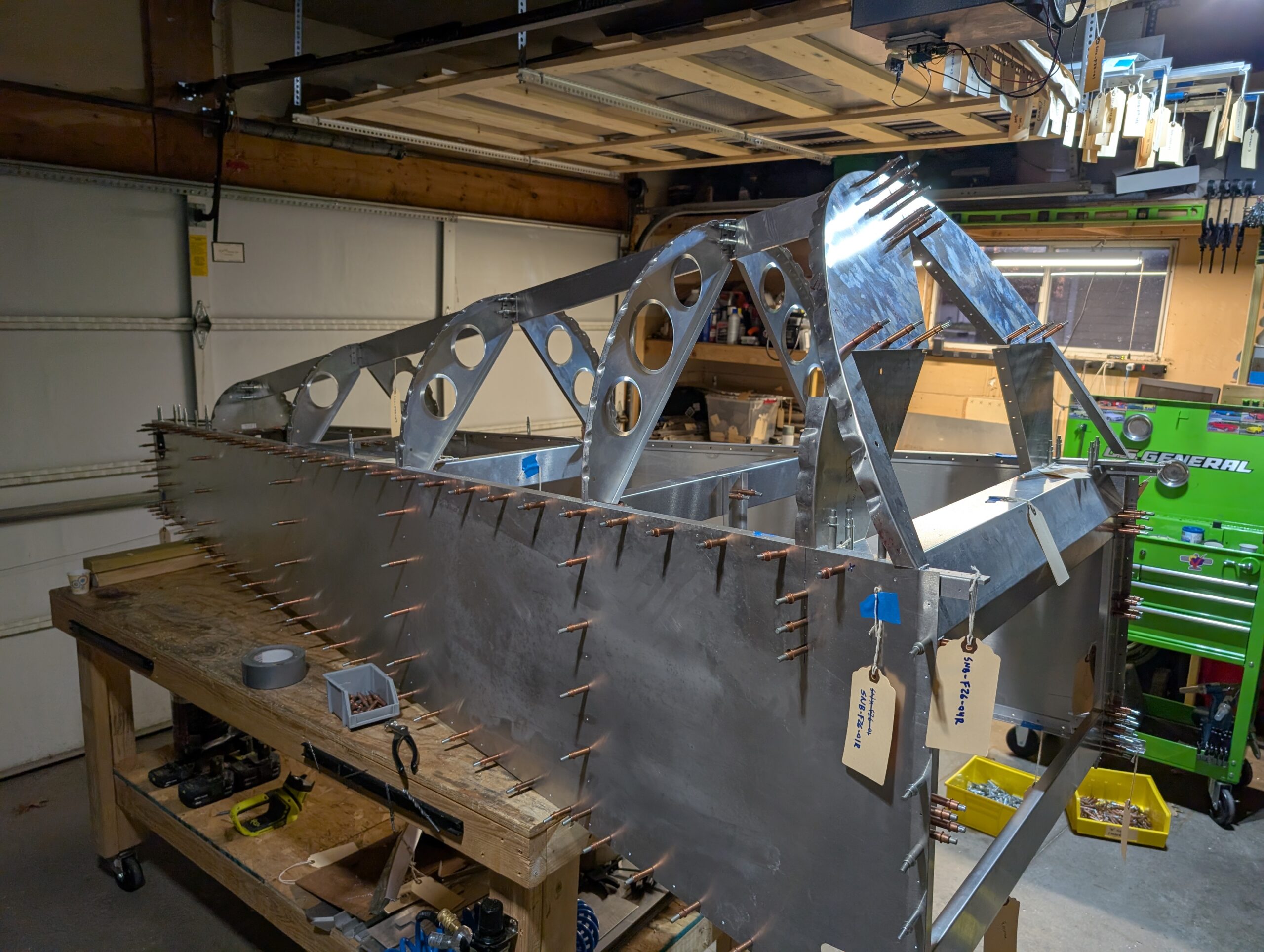

Fuselage Box Assembly – Part 8

Began reassembling aft fuselage assembly by clecoing upper and lower crossties to aft fuselage side panels. Hours Worked: 0.75

-

Fuselage Box Assembly – Part 7

Up drilled mount assemblies and aft shear web. Reinstalled aft fuselage floor and up drilled AN525 holes for splice plates in lower formers. Also up drilled top AN525 holes through upper longerons, splice plates, and crosstie box. Inserted F22-07 between lower crosstie #1 and lower splice plates and pilot drilled assembly. Removed aft fuselage floor…

-

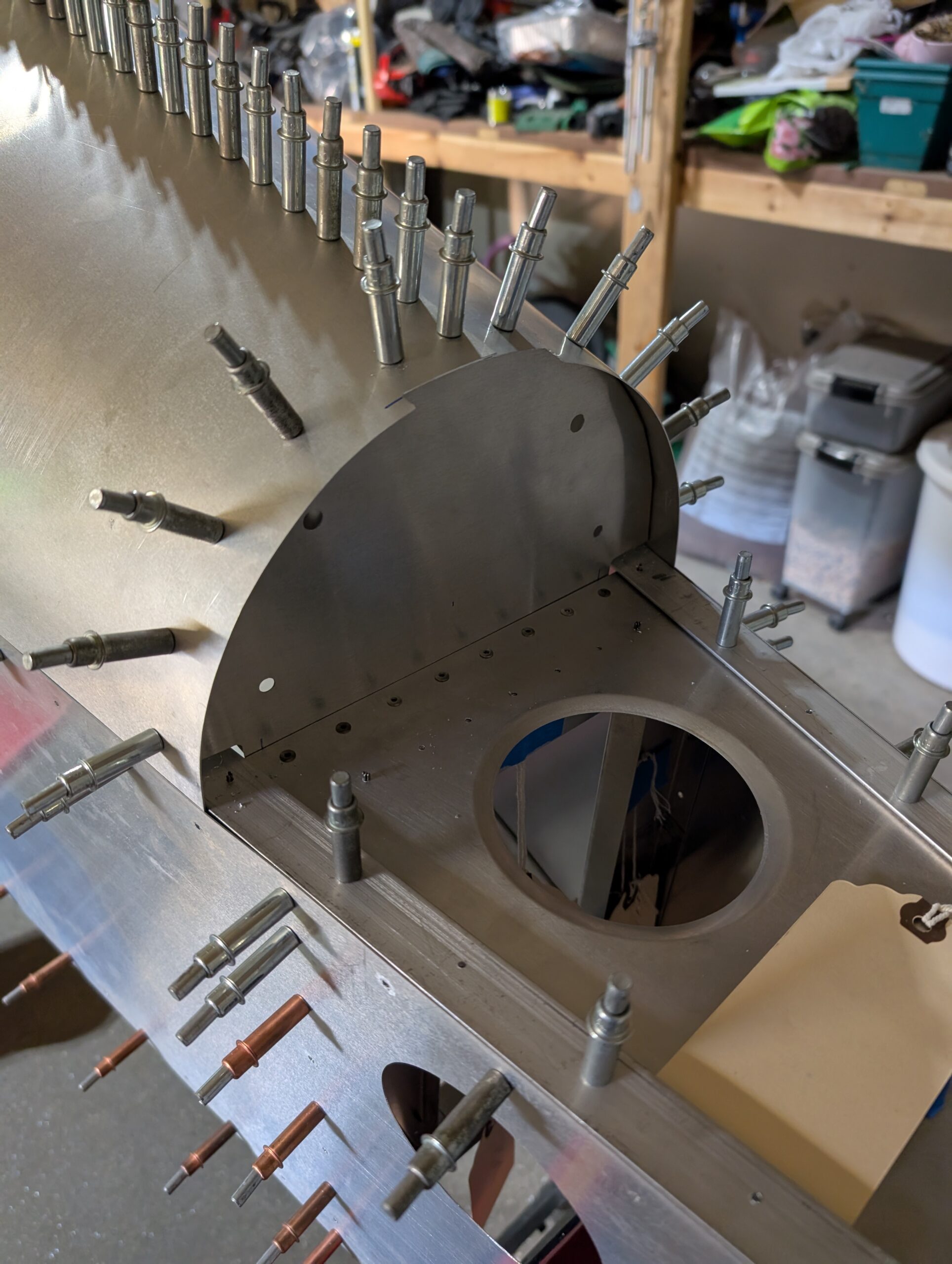

Turtledeck Assembly – Part 5

Finished up drilling #1 former area including upper and lower formers, cross tie box, side skins, and upper splice plates. After all formers were up drilled, removed both turtledeck skins for better access to skin splice channel. Up drilled skin splice channel plates then removed formers and splice channel. Hours Worked: 3.84

-

Turtledeck Assembly – Part 4

Located new #1 turtledeck formers and confirmed much better fit than previous formers. Used #30 holes in turtledeck skin and transferred to formers. Located forward skin splice channel clip and pilot drilled to skin splice channel and former #1 splice plate. Began up drilling turtledeck assembly starting from aft side and working forward. First up…

-

Aft Fuselage Side Panel Assembly – Part 4

Up drilled holes in side skin and lower splice plates for AN525 bolts. Hours Worked: 0.52

-

Turtledeck Assembly – Part 3

Located L/R former #2 against turtledeck skin. Vertically spaced formers by placing wedge between former flange and upper longeron and pilot drilled and clecoed formers to skin. Started drilling from bottom working upwards and completed left side before moving onto right side. Right side former interfered with skin splice channel so trimmed around 1/8″ from…

-

Aft Fuselage Side Panel Assembly – Part 3

Up drilled left and right aft fuselage side panels to #30. Both panels up drilled for rivets per B-model plans. Did not up drill lower splice plate bolt holes. Hours Worked: 0.80

-

Turtledeck Assembly – Part 2

Began securing turtledeck skin by pilot drilling left side (every other hole). Repeated the same process on the right side. Will finish pilot drilling sides after formers are installed. Following B-Model plans. Located former #5 by marking centerline along top and front side of former and pilot drilling top center hole in former. Located, pilot…