Wings

-

Trimming Wing Skins – Part 3

Trimming of forward Wing Skin per conversion plans Hours Worked: 0.33

-

Trimming Wing Skins – Part 2

Trimming of SNX-W19-02 to create SNX-WC01-05 Hours Worked: 0.38

-

RH Wing Assembly – Part 2

Pilot drilled lower aft wing skin to rear spar and ribs; will wait to mockup leading edge before pilot drilling main spar. Used same process as upper aft wing skin and leveled multiple times throughout process. Still need to drill aileron rib stiffeners in lower skin and make inspection hole cover but will wait until…

-

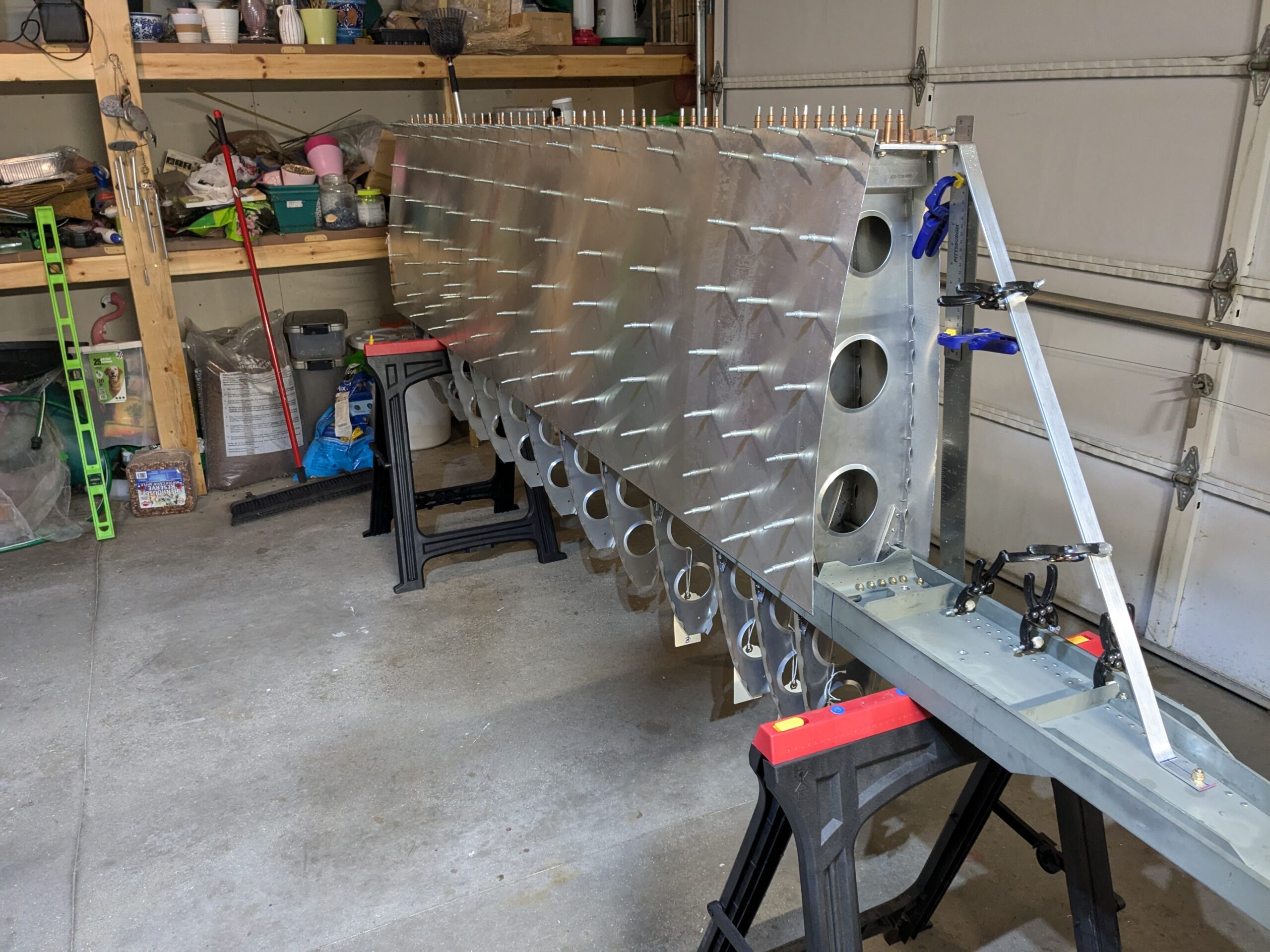

RH Wing Assembly – Part 1

RH wing re-leveled on workbench and aft spar location set at W.S. 19″ per plans. Aft upper wing skin match drilled to ribs starting at rear spar and worked forward towards main spar. Checked level again after upper aft skin clecoed in place and all looked good. Still need to drill forward spar. Hours Worked:…

-

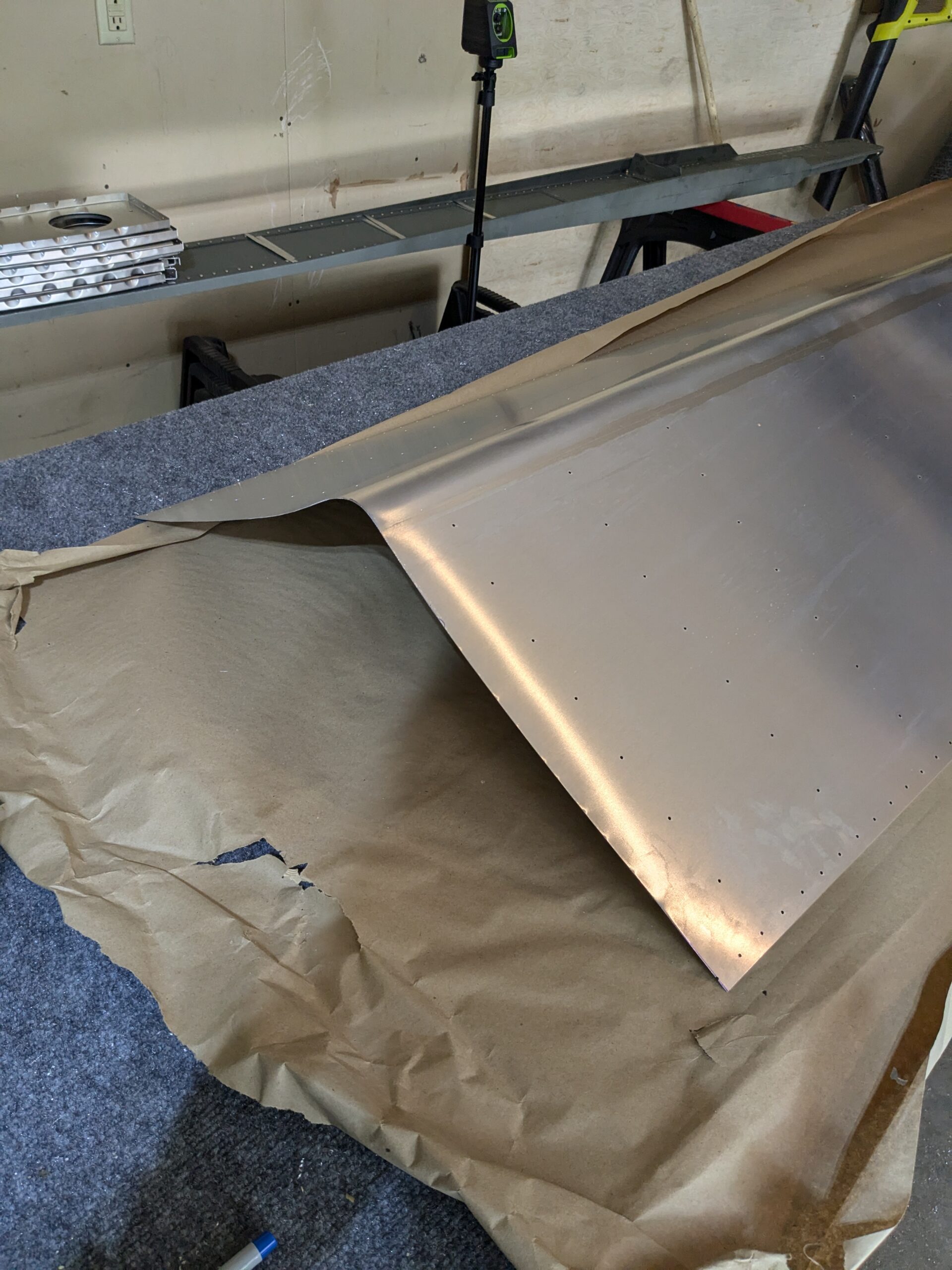

Trimming Wing Skins – Part 1

Trimmed legacy upper wing skin per conversion plans. Trimmed with Andy snips and deburred cut edge with die grinder Hours Worked: 0.75

-

RH Wing Rib Assembly – Part 1

Mockup of forward ribs on R/L wing Hours Worked: 1.32

-

RH Wing Rib Assembly – Part 2

Squared wing on level workbench using scrap wood and 3 levels chordwise. Levels blocked up with 2×4 on rear spar to ensure contact with spar cap peak. Up drilled aft ribs to rear spar holes and clecoed into place. Hours Worked: 2.72

-

Wing Rib Prep – Part 6

Finished riveting -03 and -04 forward ribs. Hours Worked: 0.55

-

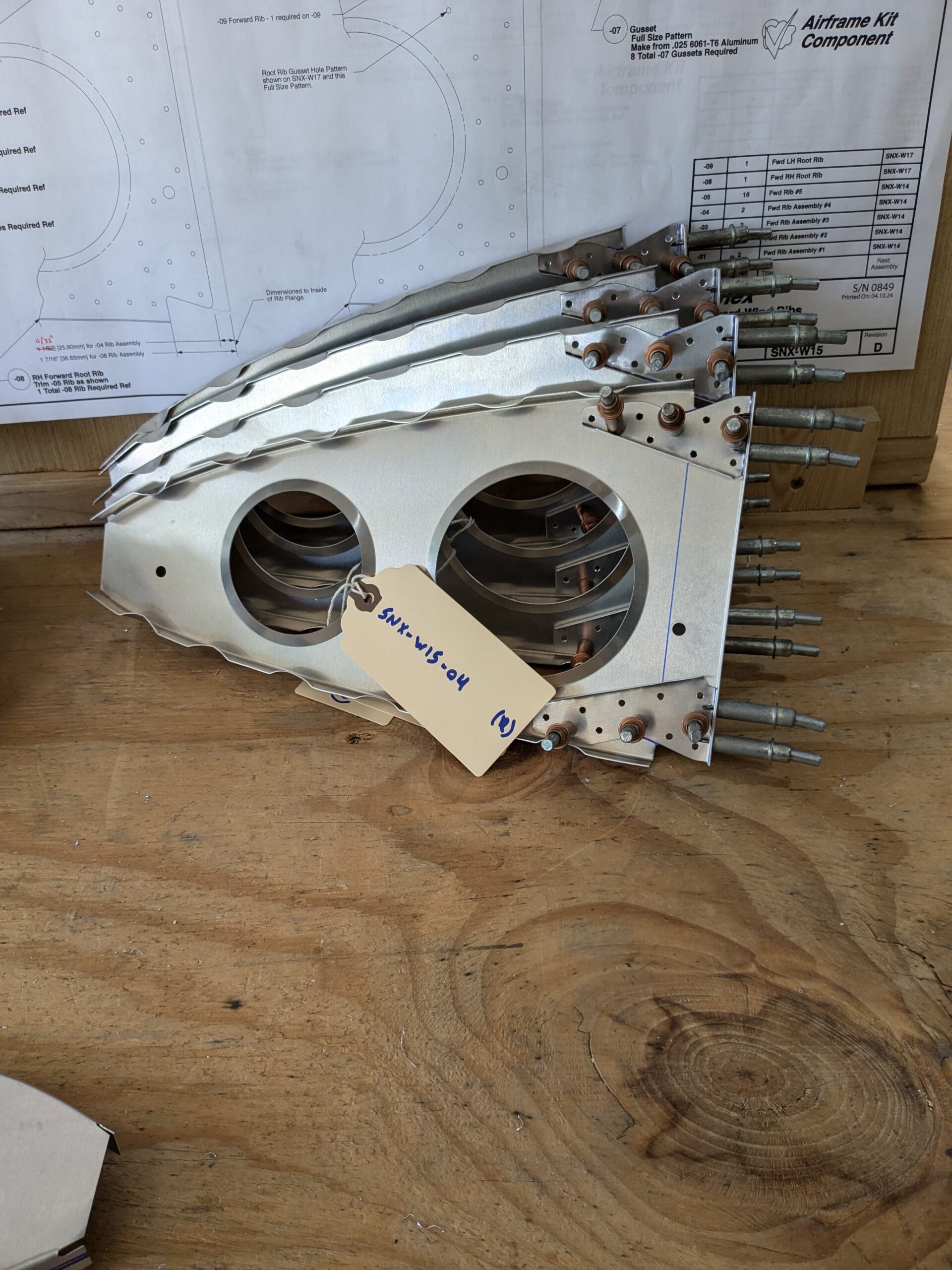

Wing Rib Prep – Part 5

Finished up trimming, match-drilling, and deburring -03 and -04 ribs. Still need to rivet. -08 and -09 forward root ribs completed Hours Worked: 2.53

-

Wing Rib Gussets

Determined pre-existing -06 and -07 gussets were from outdated plans and needed to be scrapped. New -06 and -07 gussets cut, drilled, and bent from template using scrap .025 sheet. Finished trimming -01 and -02 forward ribs and clecoed to spars. Hours Worked: 5.37

-

Wing Rib Spacers – Part 2

Mockup assembly of aft ribs, center spacers, and web spacers to spars and all pilot holes drilled through components. Creation of “skin simulators”. Need to check rib position yet. RH aileron bell crank assembly lubricated with white lithium. Hours Worked: 3.23

-

Wing Rib Prep – Part 4

Finished up drilling and riveting gussets to aft ribs #1 – #4. W16 complete! Hours Worked: 1.70