SNX-W21: Aileron Bell Crank

-

Aileron Bellcranks – Part 4

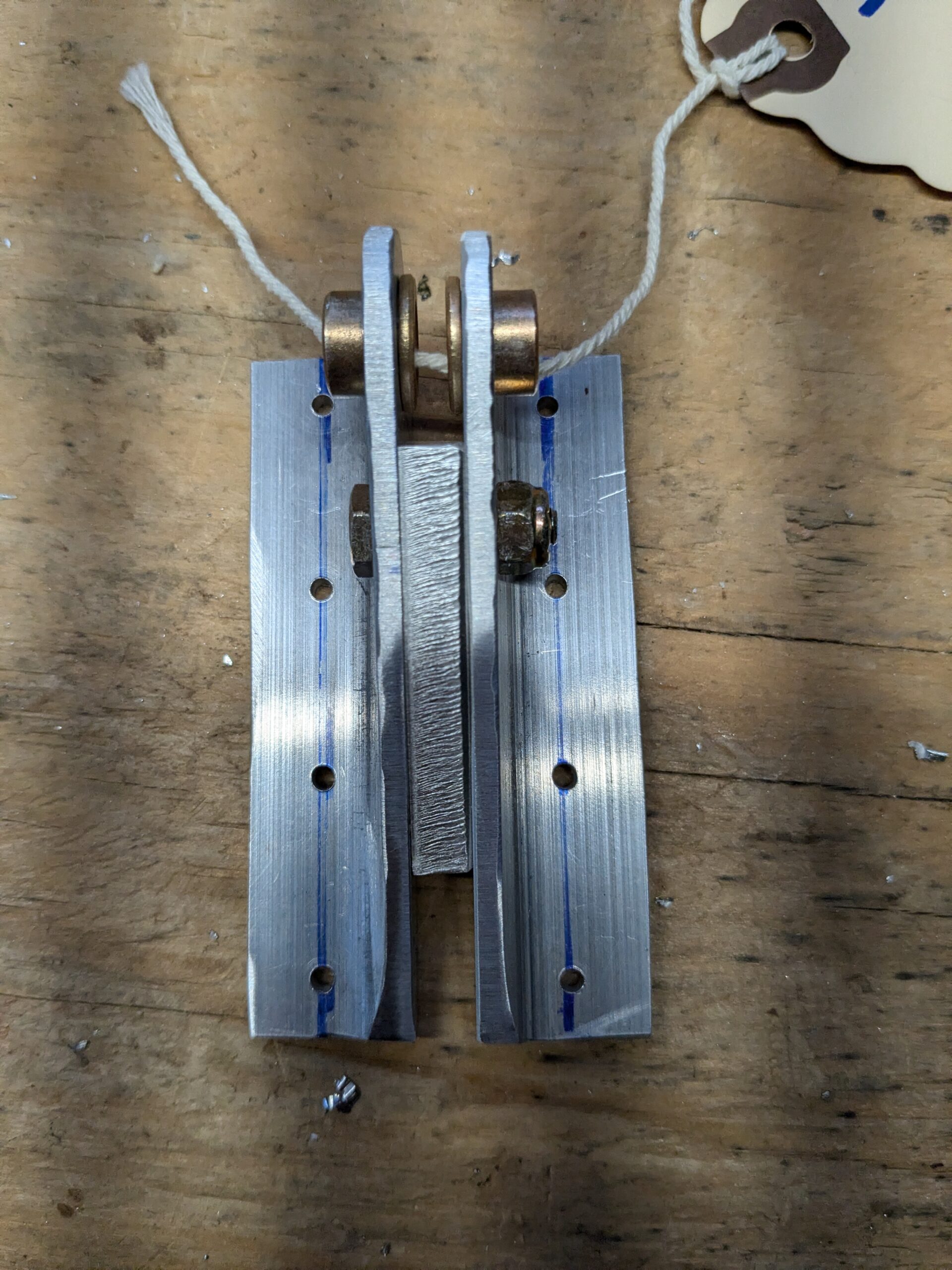

Drilling of holes in -13L/R and -14L/R vertical channels. Both -10 bell crank assemblies created. Two washers per assembly needed to get castle nut aligned properly. Completed -01L including final riveting and lubrication of pivot with white lithium grease. -08 clip heights on vertical stiffeners set by using right angle from rib face. -01R clecoed…

-

Aileron Bellcranks – Part 5

Used Loctite 638 retaining compound to hold Symmco bearings into place; worked very well. Assembled together angles to create pivot assembly then added -10 bell crank assembly and completed final riveting onto -01R to complete #9 rib assembly. Will let Loctite harden before greasing with white lithium per plans. Hours Worked: 1.71

-

Aileron Bellcranks – Part 3

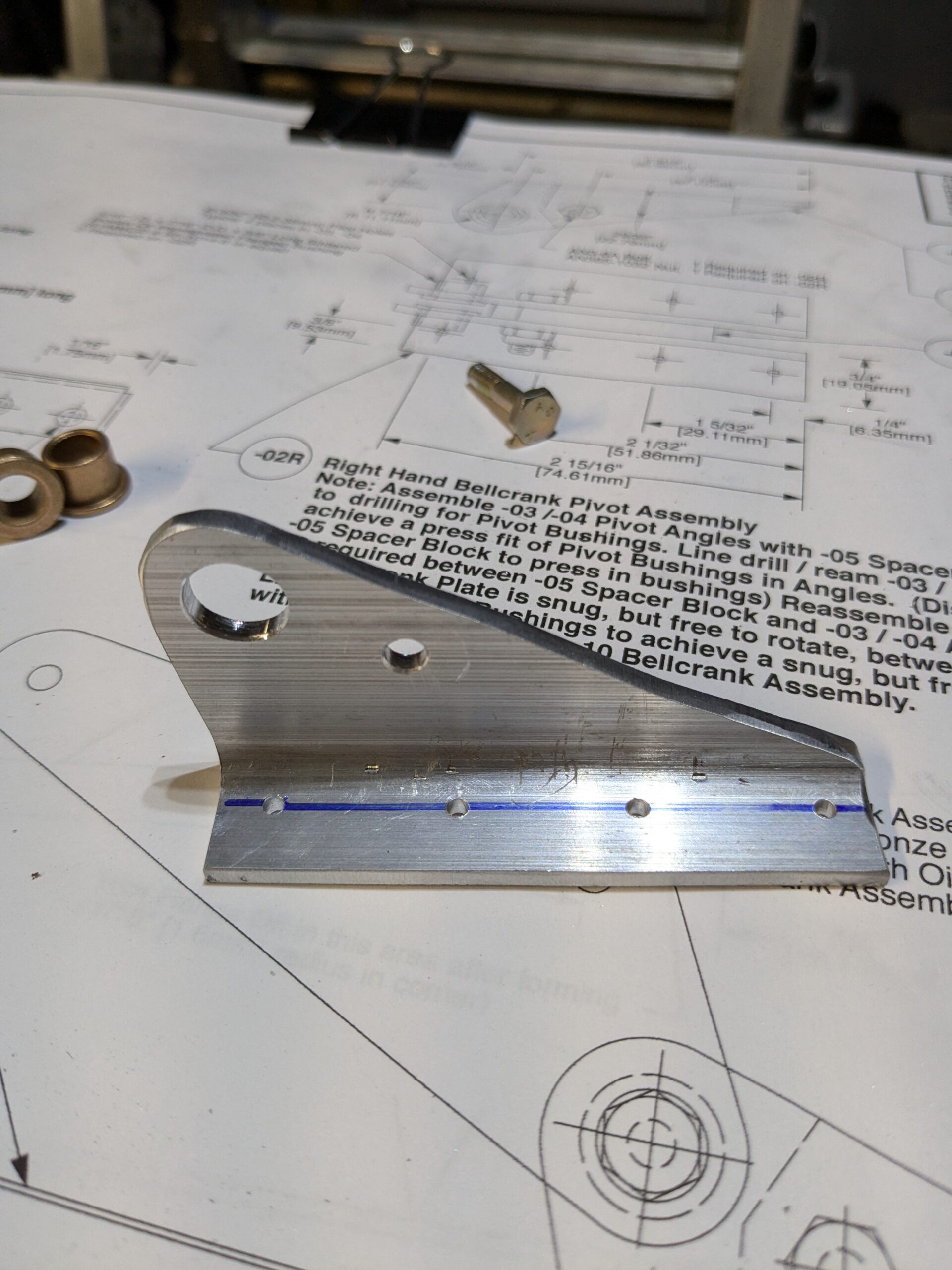

Machined -06 and -07 angles from template and press fit Symmco bearings to create -02L assembly. (8) -09 clips cut from Z01-03 stock, drilled and completed, and -13/-14 channels cut (but not yet drilled). Hours Worked: 3.75

-

Aileron Bellcranks – Part 2

Cut new blanks for -03 and -04 and cut out angles. Mated together angles and up drilled bolt hole through -05 spacer block. Symmco bushings are just a little loose in holes so will need to apply Loctite 638 before final assembly. Hours Worked: 1.34

-

Aileron Bellcranks – Part 1

Cut blanks and made templates for -03, -04, -06, and -07 angles. Made an error drilling holes for -03 and -04 angles and will need to scrap angles and create two more blanks Hours Worked: 2.67