AN365-1032A

-

Forward Fuselage Part Prep – Part 2

Assembled F10-16 idler assembly (skipping -21 and -17 sub assemblies. Used vice to press in Symmco bushings to pivot angles. Lubricated bushings and pivot bearings with LPS-2 prior to assembly. Hours Worked: 0.57

-

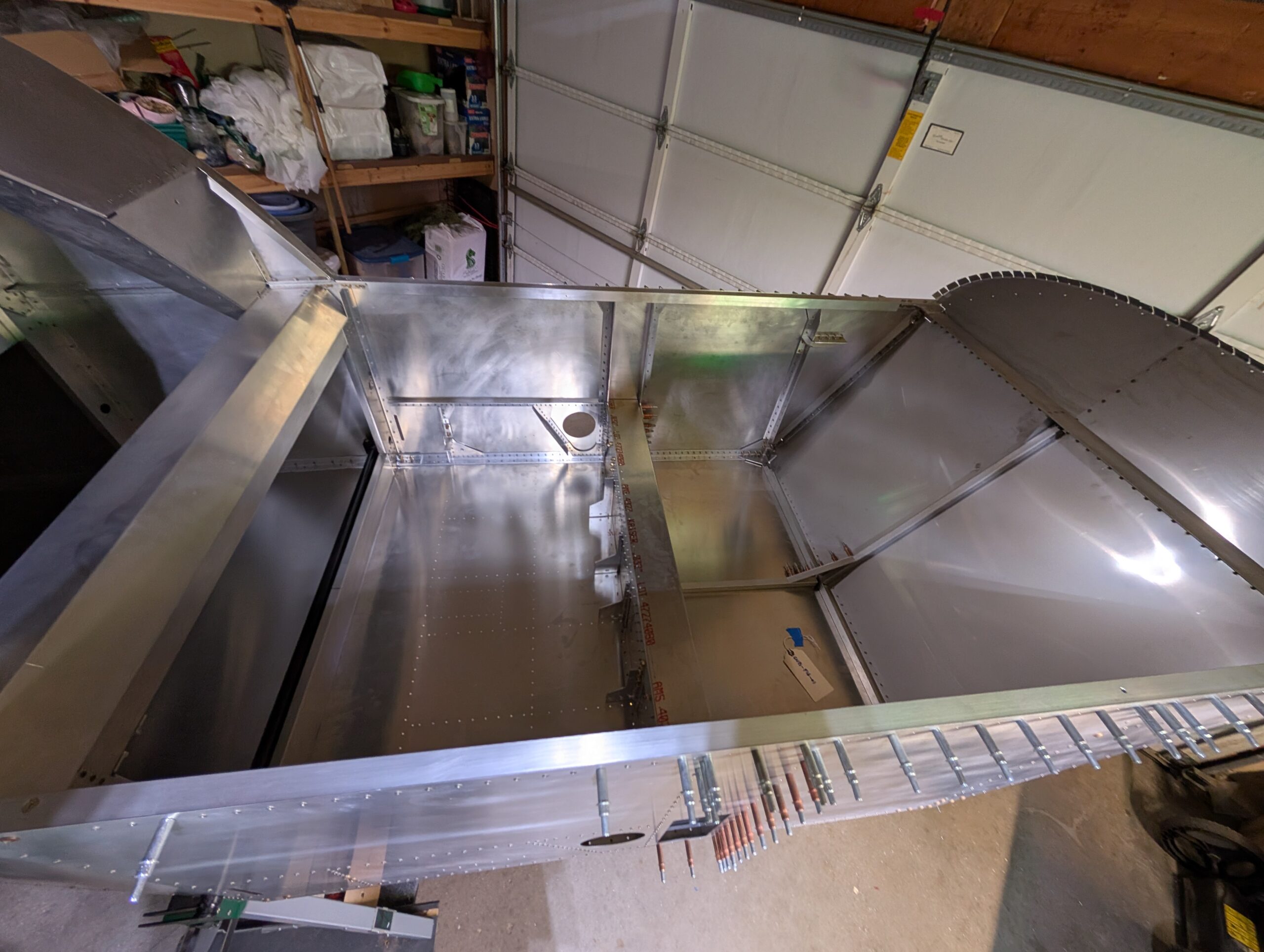

Forward Fuselage Assembly – Part 6

Clecoed lower floor/firewall stiffener and floor stiffener into place. Deburred upper firewall and riveted to fuselage box. Deburred forward fuselage floor and clecoed into place. Will wait until very end to rivet floor into place. F11 complete! Hours Worked: 1.42

-

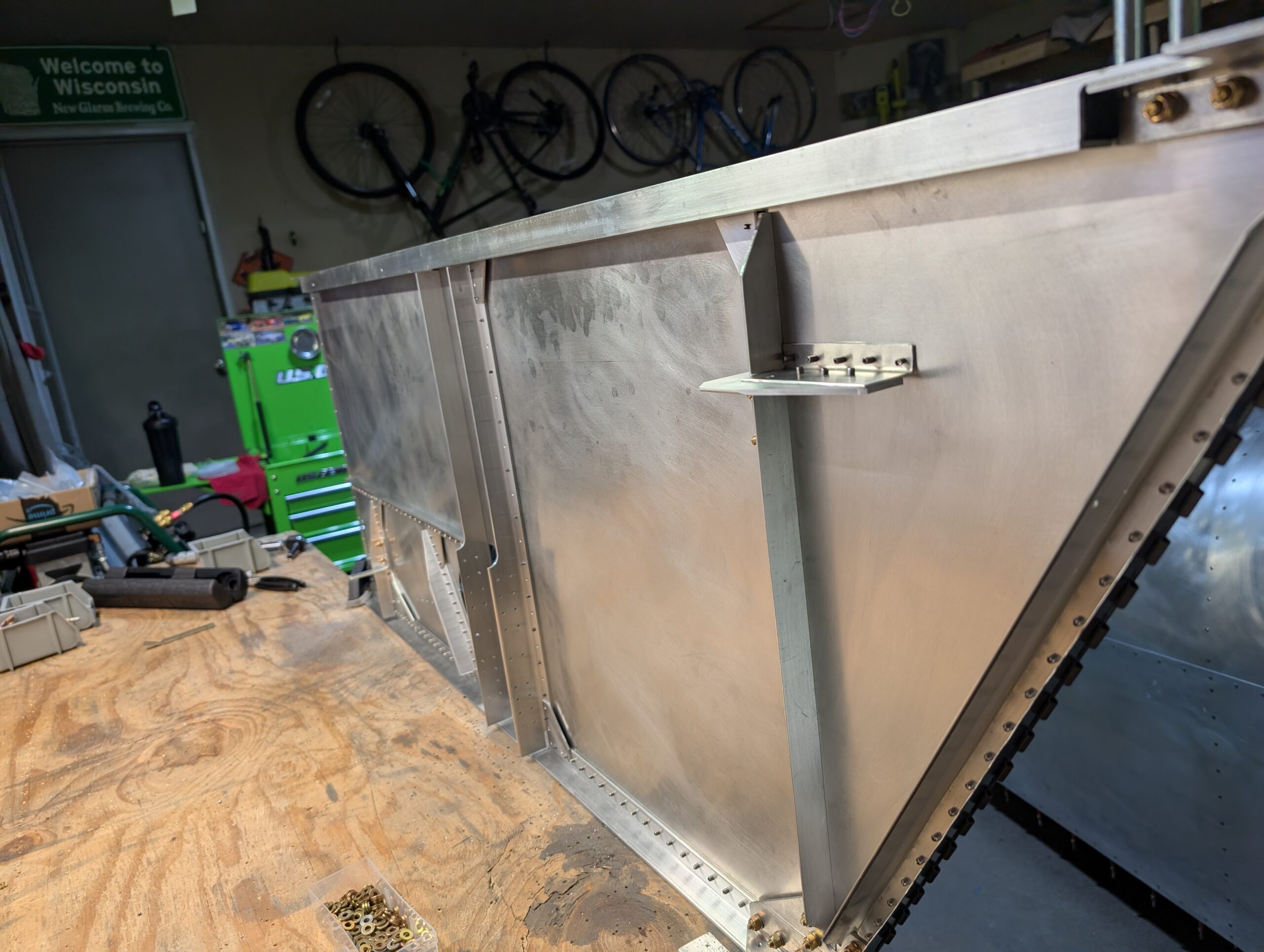

Fuselage Side Panels – Part 6

Up drilled LH forward side panel then disassembled and deburred/cleaned all parts. Clecoed assembly back together and installed rivets per plans. Installed AN525 hardware as called out in plans and torqued to spec. F12-01L and F12 complete! Hours Worked: 5.00

-

Fuselage Side Panels – Part 5

Disassembled RH forward side panel and deburred/cleaned all parts. Clecoed assembly back together and installed rivets per plans. Installed AN525 hardware as called out in plans and torqued to spec. F12-01R complete. Hours Worked: 3.97

-

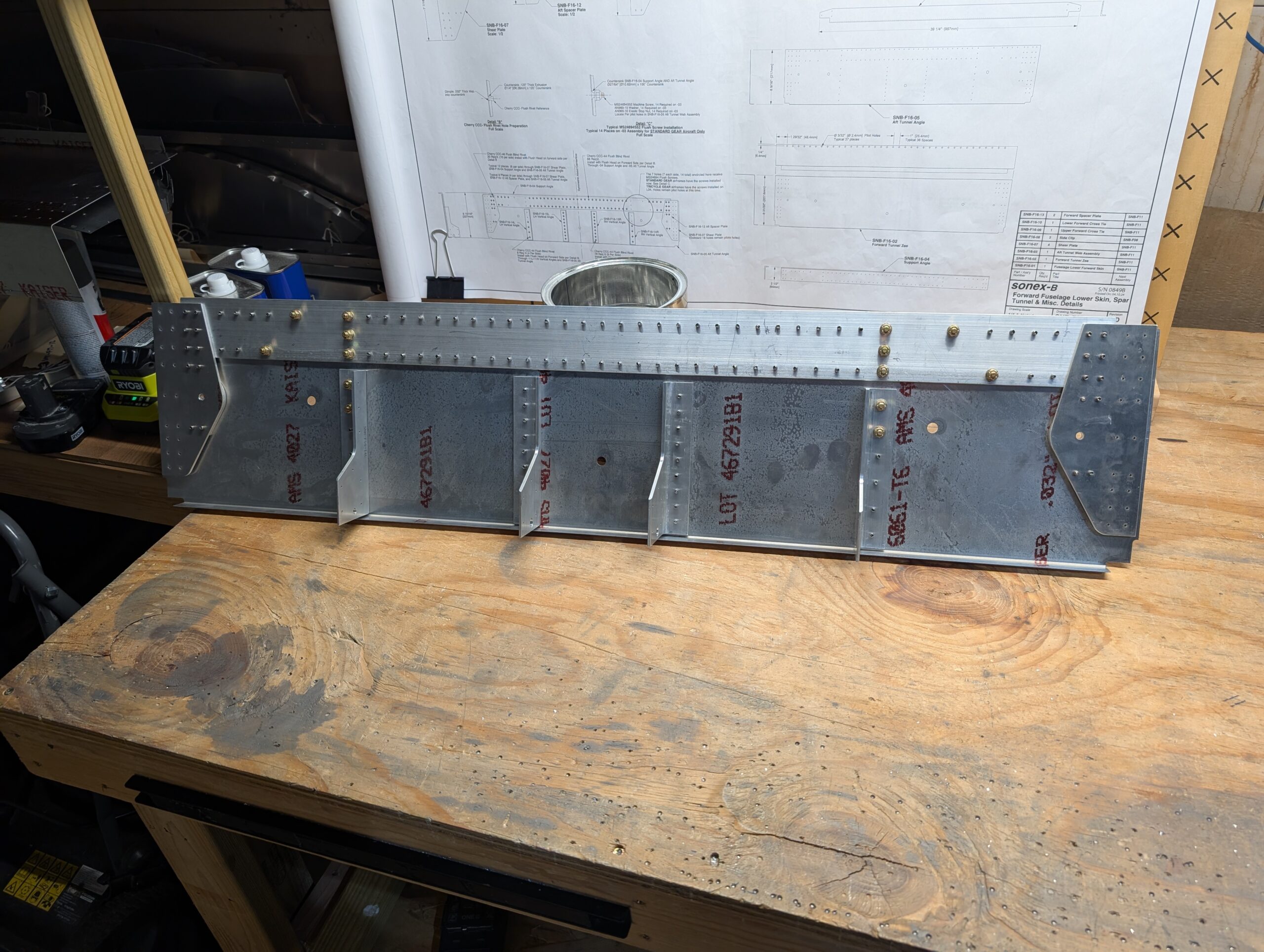

Forward Fuselage Part Prep – Part 2

Created -08 clips per legacy plans out of Z01-03 stock. Up drilled -03 assembly then dimpled aft -05 tunnel angle. Countersunk -04 support channel, -12 spacer plates, and -14L/R and -15L/R angles. Refitted components together, installed MS24694 bolts for standard gear configuration, and riveted with CCC rivets. F16 complete! Hours Worked: 4.85

-

Tail Cone Box Wrapup

Riveted turtledeck assembly to fuselage tail cone box per plans revision E. Up drilled holes through side skins and upper splice plates to 3/16″ and installed AN525 hardware. Torqued to spec. Clecoed crosstie closeout plate into place and riveted into place. Clecoed flap motor actuator mounts into place and verified alignment with flap drive tube…

-

Turtledeck Assembly – Part 8

Riveted formers #5 through #2 to turtledeck skin starting at upper longerons and moving towards the skin splice channel. Riveted lower #1 formers to back of cross tie box then riveted upper #1 formers to turtledeck skin assembly. Riveted F20-08 splice plate to upper skin splice channel and #1 formers. Wrapped up #1 former section…

-

Flap Drive Tube Installation

Located flap drive angles per plans and pilot drilled/clecoed into place. Marked center of lower crosstie #1 and flap drive tube and centered flap drive tube. Marked location of flap mount blocks and drilled 3/16″ holes in lower splice plates. Needed to notch out lower crosstie #1 to clear flap mount blocks. Up drilled lower…

-

Fuselage Box Assembly – Part 10

Riveted upper cross tie #2 to vertical channels and upper cross tie box to vertical channels #1. Fit cross tie splice plates to upper splice plates via AN3 bolt holes and riveted plates to cross tie box. F21 complete! Hours Worked: 0.67

-

Aft Fuselage Side Panel Assembly – Part 5

Began final assembly of side panels by deburring, scotchbriting and cleaning all F25 parts. Started by riveting rudder cable fairlead mount blocks to vertical channels #1 and #5. Riveted lower longerons to aft fuselage side skins along with vertical channels #2-#5. Left vertical channel #1 just clecoed for now. Left top row of rivets on…

-

Aileron Bellcranks – Part 5

Used Loctite 638 retaining compound to hold Symmco bearings into place; worked very well. Assembled together angles to create pivot assembly then added -10 bell crank assembly and completed final riveting onto -01R to complete #9 rib assembly. Will let Loctite harden before greasing with white lithium per plans. Hours Worked: 1.71

-

Aileron Bellcranks – Part 4

Drilling of holes in -13L/R and -14L/R vertical channels. Both -10 bell crank assemblies created. Two washers per assembly needed to get castle nut aligned properly. Completed -01L including final riveting and lubrication of pivot with white lithium grease. -08 clip heights on vertical stiffeners set by using right angle from rib face. -01R clecoed…