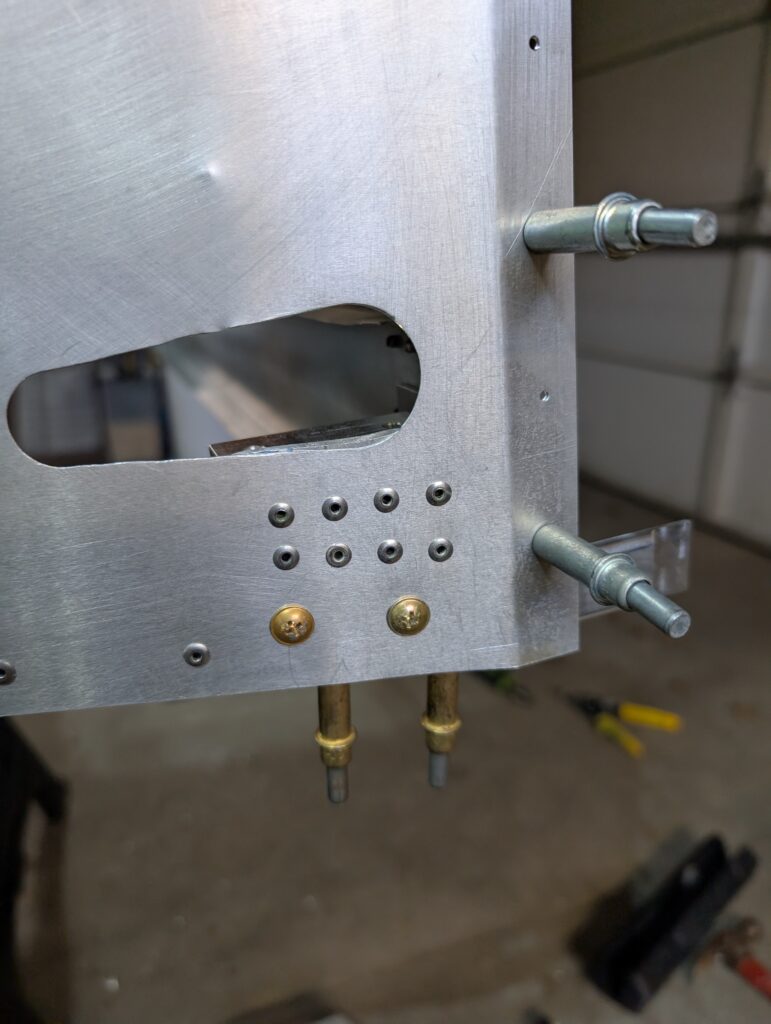

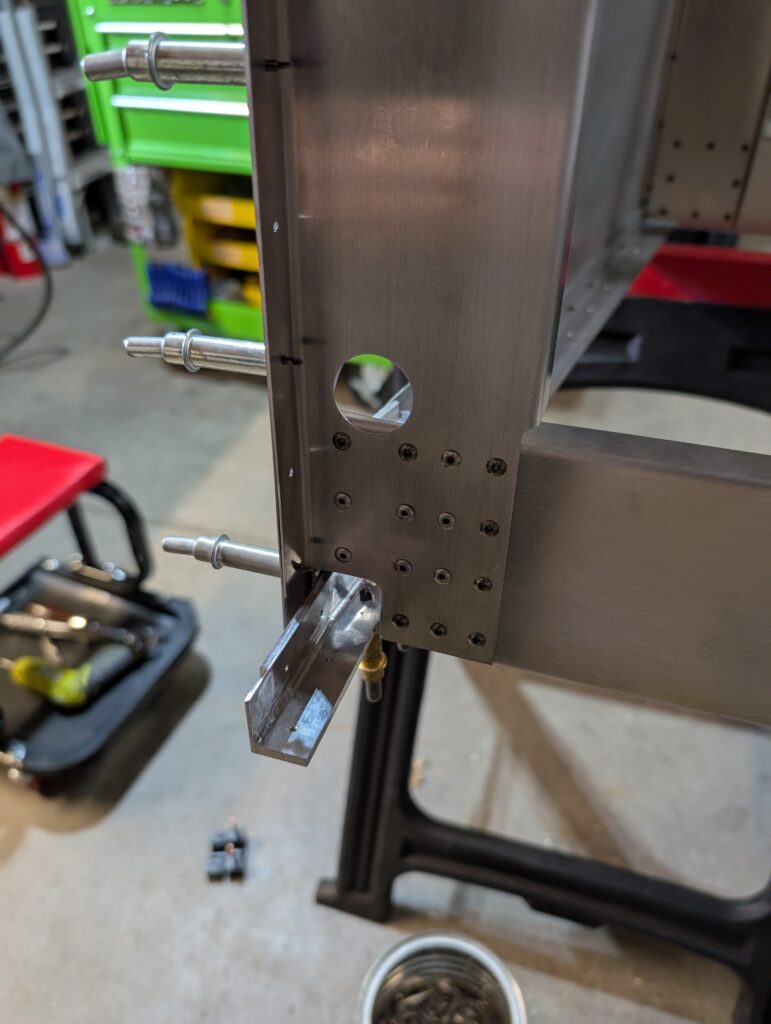

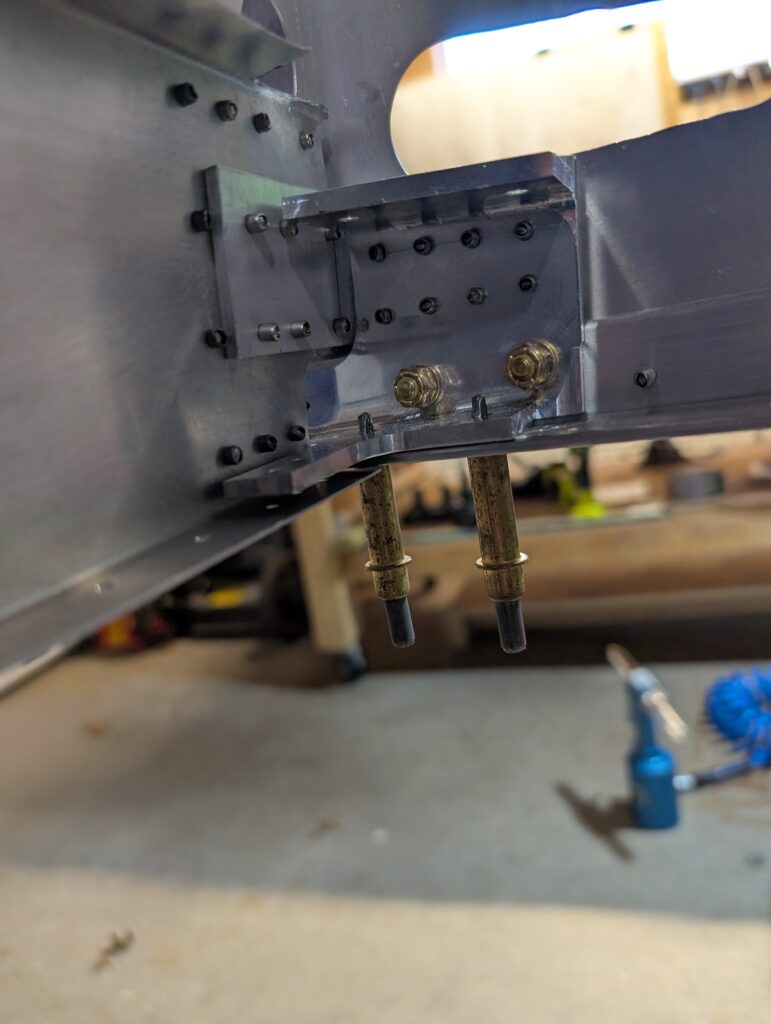

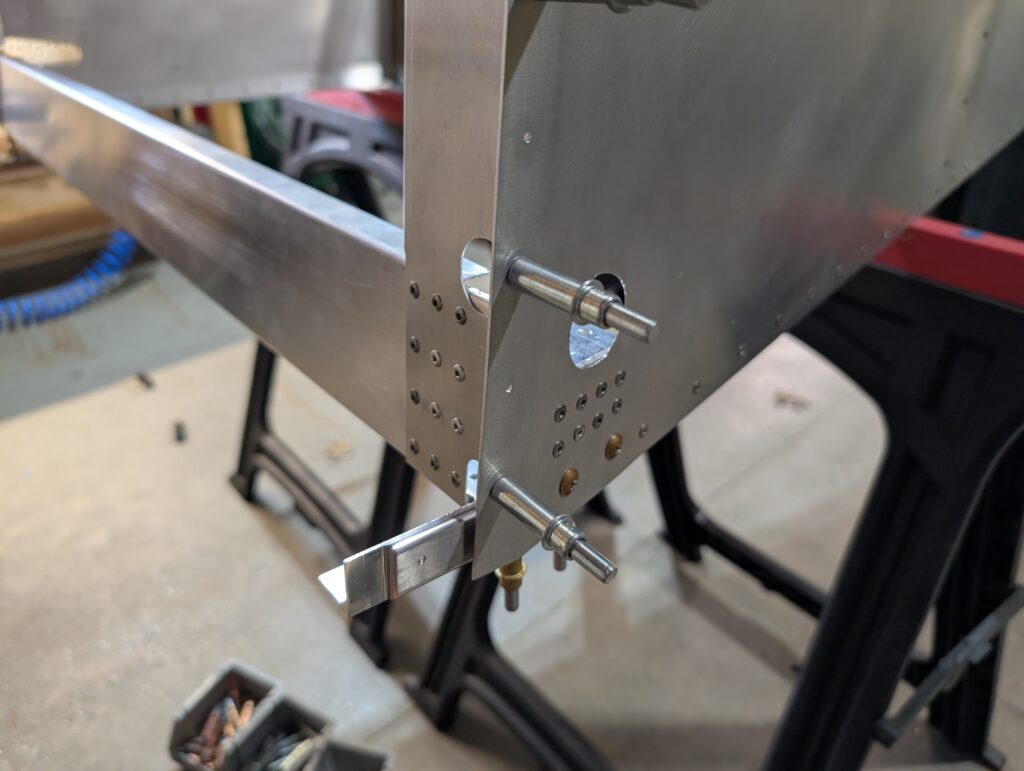

Located flap drive angles per plans and pilot drilled/clecoed into place. Marked center of lower crosstie #1 and flap drive tube and centered flap drive tube. Marked location of flap mount blocks and drilled 3/16″ holes in lower splice plates. Needed to notch out lower crosstie #1 to clear flap mount blocks. Up drilled lower splice plates, flap drive angles, side skins, and lower crosstie #1. Disassembled components, deburred, slightly enlarged LH flap drive tube hole, and riveted flap drive angles, lower splice plates, and lower crosstie #1. Marked location of mount blocks on drive tube and removed powder coating with drill and wire wheel. Aligned flap drive tube in flap mount blocks, lubricated with white lithium grease, and installed flap drive tube with AN3 hardware. Torqued hardware based on movement rather than standard torque spec. Flap drive tube is free to rotate but takes some firm effort. Will adjust if needed after actuator is installed.

Hours Worked: 3.98

Leave a Reply