Wings

-

Wingtip Installation

Installed nutplates for wingtip light fairings onto wing tips and riveted wingtips onto wings with AAP-42 aluminum rivets. After wingtips were installed, sanded rivets in preparation of paint. Hours Worked: 1.30

-

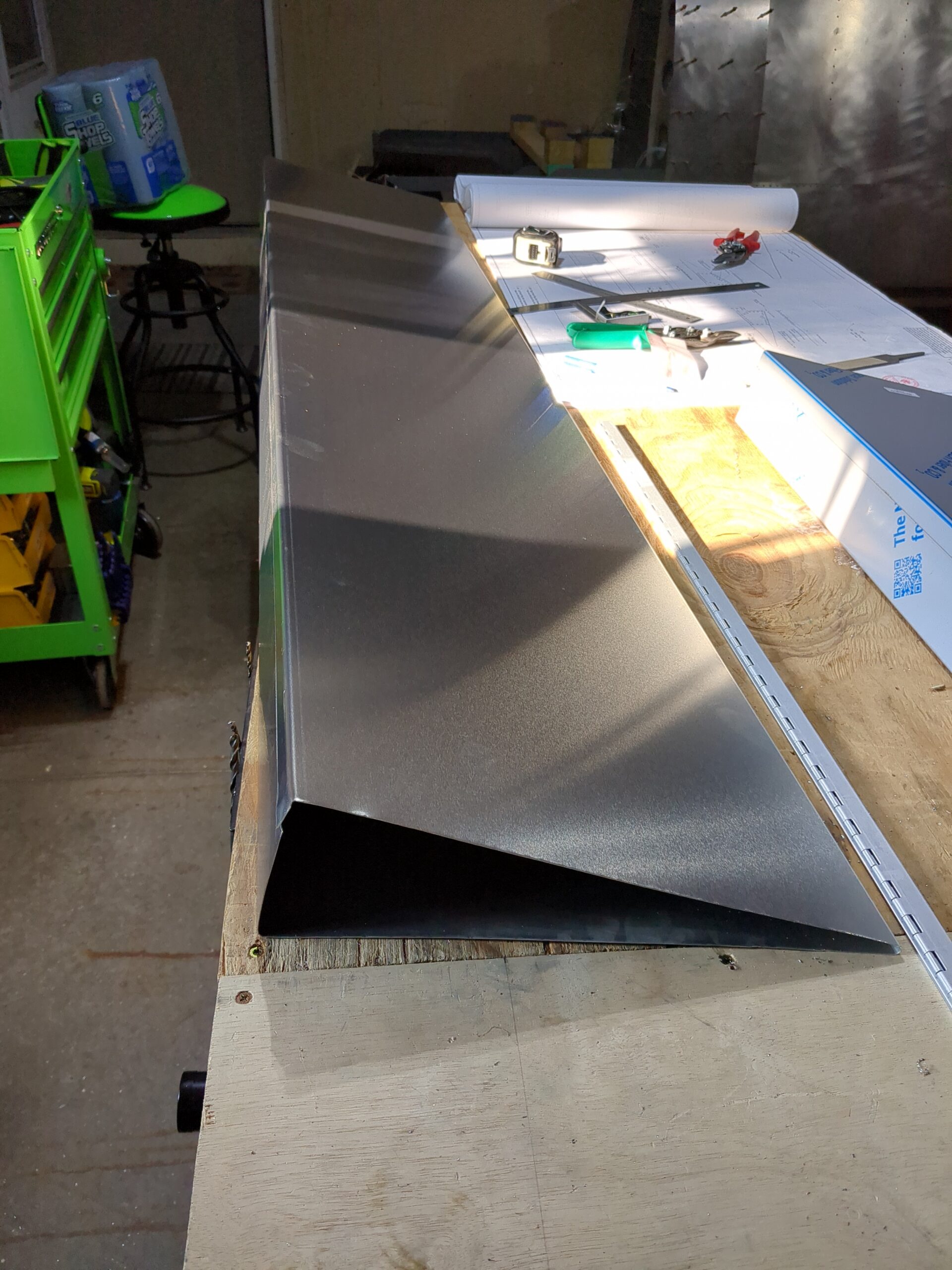

Wing Tip Finishing – Part 2

Removed wing tips from wing after letting SuperFil cure. While not the most elegant (or clean) epoxy job, it did take up the gap pretty well. Removed packing tape from edge of wing and lightly reshaped the edge of the wingtips. Removed ailerons and faps from the wings to prepare for paint. Hours Worked: 0.90

-

Wing Tip Finishing – Part 1

Began prepping wingtips and tip light fairings for paint and final finishing. Located tip lights onto wing tip light fairings and drilled wire pass through hole and mounting screw holes; tip lights will attach to fairing with Dynon panel screws and elastic nuts. Located tip light fairings on the wing tips by aligning center of…

-

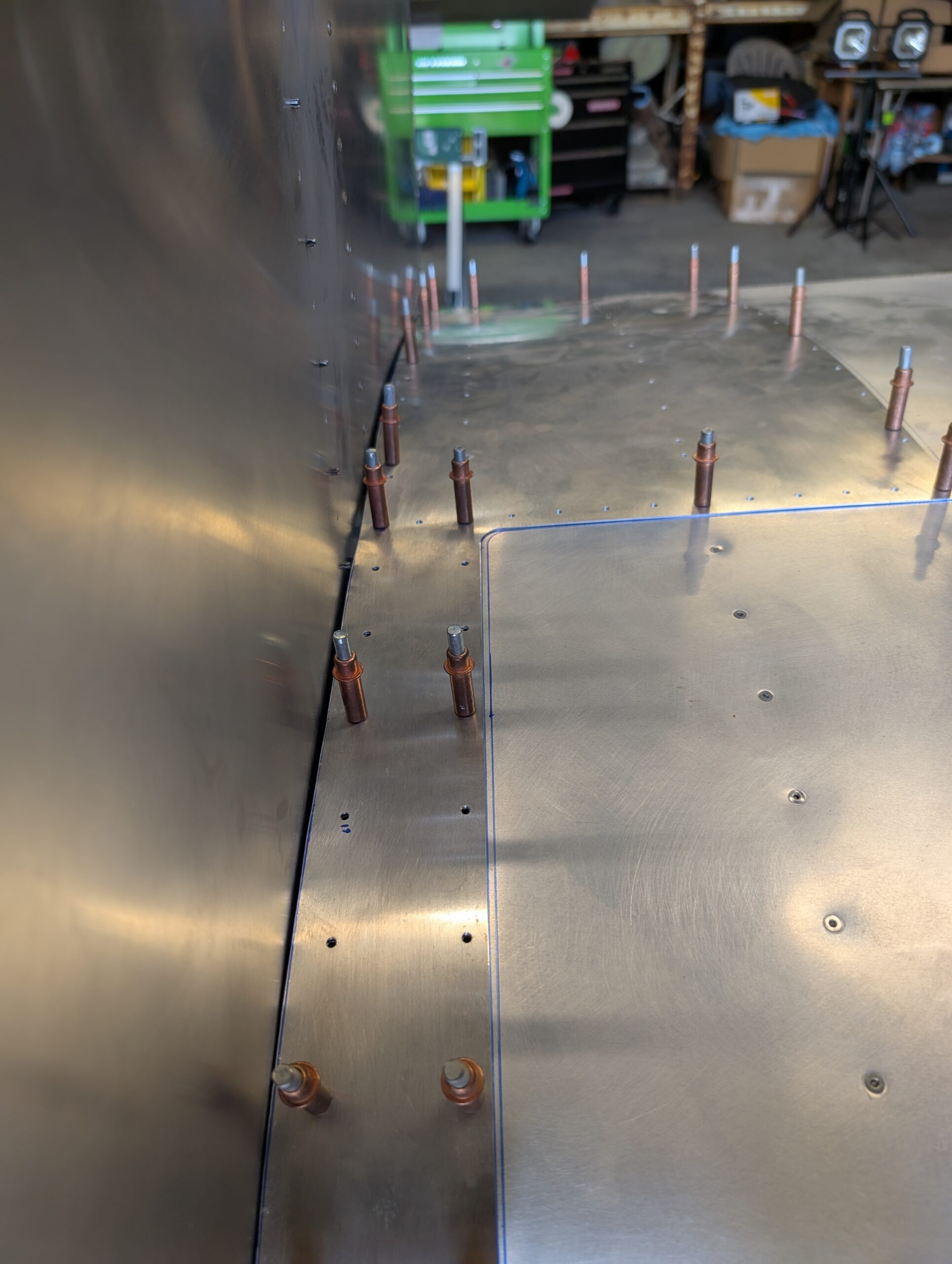

Wing Root Doublers – Part 2

Measured wing root doubler trim distances off of wing skin at each rivet hole and transferred measurements onto inside edge of wing root doublers. Trimmed excess material off with snips then deburred edges. Clecoed wing root doublers onto wing and verified clearance from fuselage sides was between 1/32″ and 1/16″. Hours Worked: 1.89

-

Wing Root Doublers – Part 1

Slid wings out from fuselage (one at a time) and reinstalled wing root doublers with clecoes. Marked current edge of doublers onto wing skins with sharpie. Removed doublers then slid wings back into spar tunnel and pinned into proper place. Set wing doublers onto wings and slid them flush with fuselage side skins. Marked a…

-

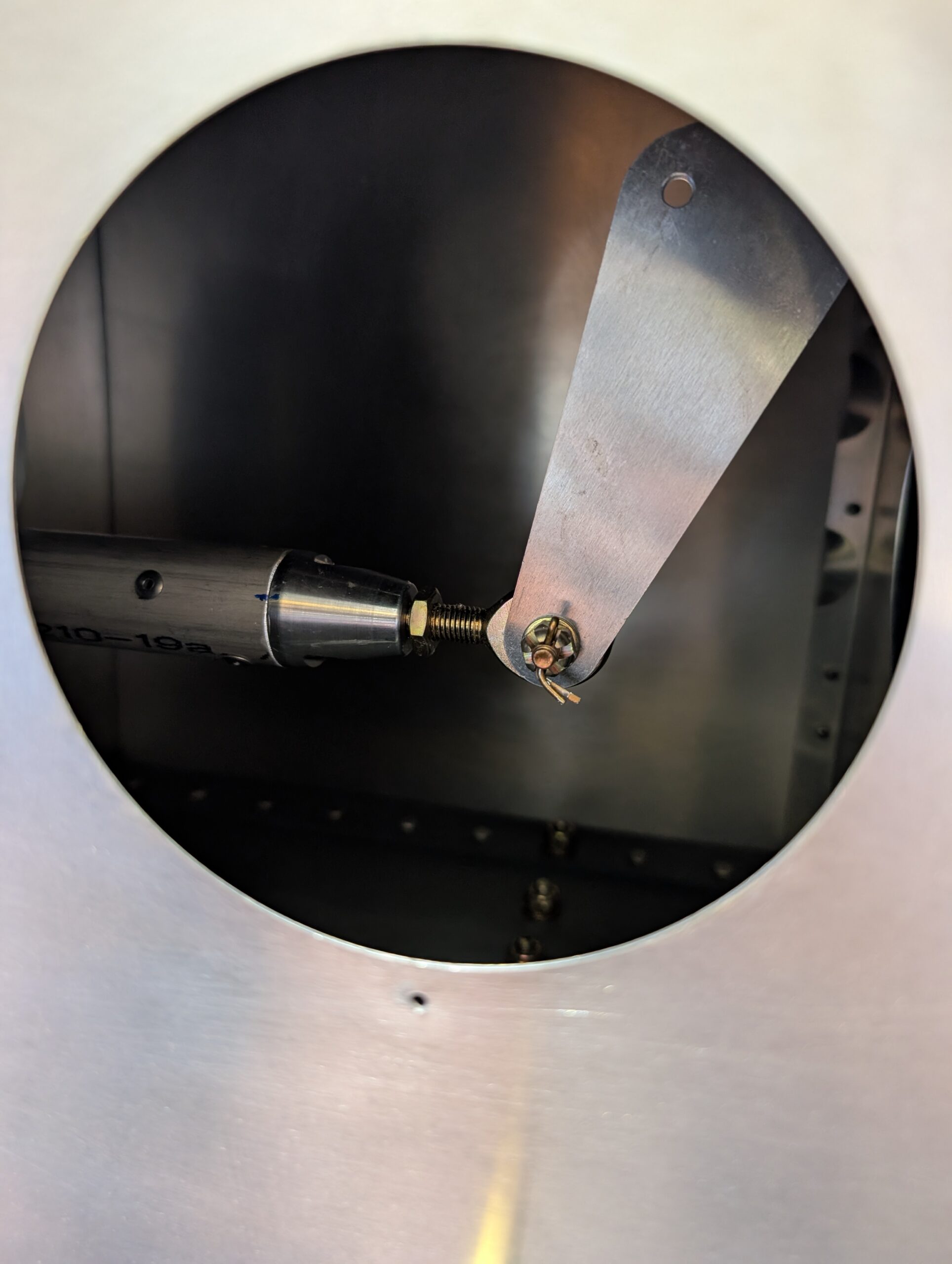

Wing Pushrod Installation – Part 1

Removed aileron bellcrank access covers from wings and inserted C03-01 main aileron pushrods into wings. Attached to aileron bellcrank with AN3 hardware and castle nut. Installed C03-03 flap pushrods onto flaps with AN4 hardware. Hours Worked: 0.98

-

Flap Rebuild – Part 5

Up drilled drive plate attach holes to 1/4″ for AN4 hardware and clecoed AN366F-428A nutplates into place. Disassembled both drive plate ribs, deburred, and riveted assemblies together Hours Worked: 0.92

-

Flap Rebuild – Part 6

After completion of the drive rib assemblies, reclecoed assemblies together and completed final riveting. Flaps installed onto wings and appear to fit well. Hours Worked: 1.87

-

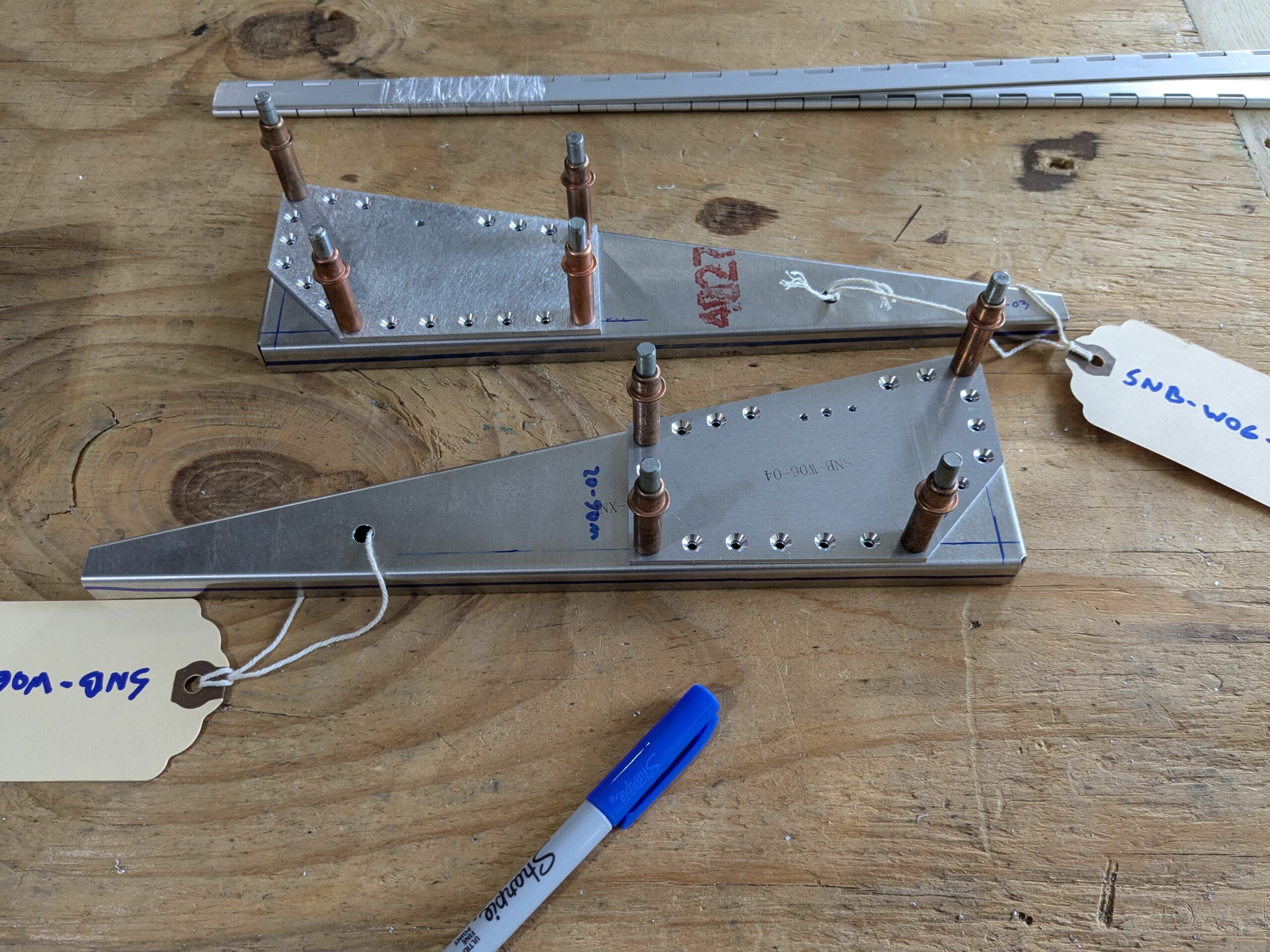

Flap Rebuild – Part 4

Disassembled both LH and RH flap assemblies and deburred all parts. Cut out holes in -01L/R flap skin for flap tie rod clearance and reassembled flap assemblies with clecoes. Scotchbrited and acetoned all parts. Both assemblies ready for final riveting pending completion of SNB-W06-05L/R drive plate assembly nutplate installation Hours Worked: 2.90

-

Flap Rebuild – Part 2

Pilot drilled and up drilled -04 flap drive plates to -02 and -03 flap ribs. Countersunk flap drive plates for CCC-44 rivets. Deburred assemblies and clecoed together pending receipt of nut plates. Cut -06L/R hinge halves from -P3 piano hinge and pilot drilled hinge halves per plans. Although hinge halves have different part numbers, no…

-

Flap Rebuild – Part 3

Laid out flap rib holes on RH flap skin, center punched, and drilled. Bottom side skin cutout for flap pushrod marked. Lined up ribs under flap skin and began pilot drilling ribs starting with top side, upper hole on forward side, then hinge-half strip, and finally lower side. Set 1/16″ hinge half offset by using…

-

Flap Rebuild – Part 1

After discussion with Sonex tech support, decided to scrap previously built flaps due to notch-out of skin on forward edge. Trimmed and deburred Z02-02 flap skin stock per plans to create -01L/R flap skins. Notches for flap pushrod yet to be cut. Mocked up -04 flap drive plates to flap ribs and pilot drilled. Discovered…