AN365-832A

-

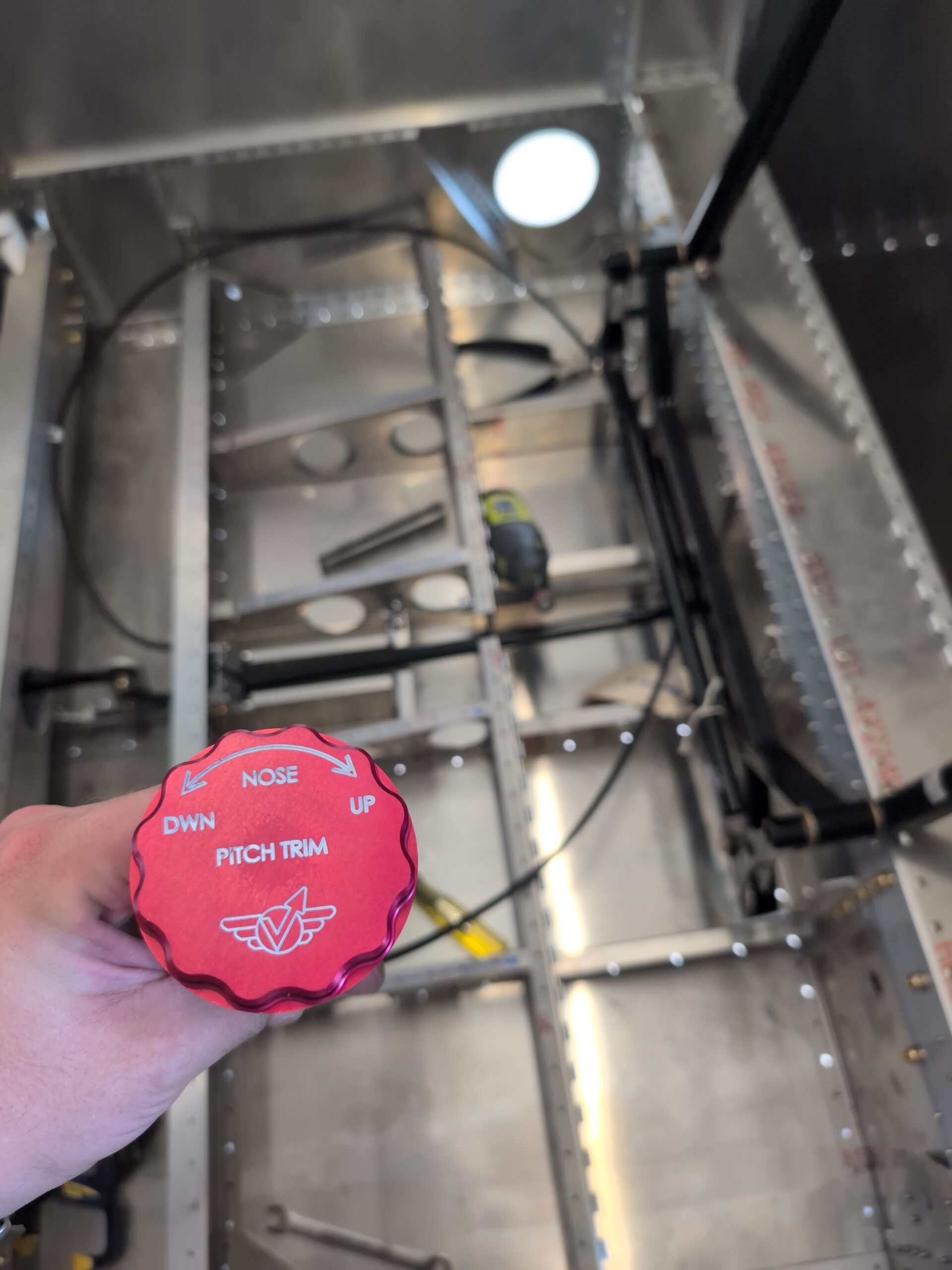

Trim System Installation – Part 1

Began trim system installation by removing lower instrument panel and drilling holes for throttle, mixture, and trim wheel. Measured and drilled hole for trim cable sleeve below seat pan. Mocked up cable run and trimmed around 18″ from cable and sleeve. Ran cable through trim adjuster and sleeve then secured to rear spar carry through…

-

Canopy Components – Part 3

Clamped canopy frame components together and checked fitment on fuselage. Forward windshield flange might need a bit of trimming but overall fit good. Pilot drilled then updrilled forward and aft canopy bows to side rails. Cut canopy hinge pieces from P5 piano hinge stock then pilot drilled per plans. Modified hinge pin per plans and…

-

Wing Root Electrical Connectors

Removed rigging hardware from main wing spars through the three center holes in the spar webs. Slid RH wing out slightly for better access to fuselage side. Located wing root electrical connector and cut out hole for pass through. Drilled mounting holes then used 8-32 screws to attach bulkhead connector to fuselage side. Measured out…