MS24665-132

-

Rudder Control System – Part 2

Heated up C01-03 rudder spring stock with propane torch and bent springs to specs in plans. Previously tried to bend springs without heat and spring steel broke rather than bent. After installing springs into fuselage, discovered that plan dimensions were a little long and resulted in rudder pedals not returning to neutral. Shortened springs by…

-

Control Stick Assembly – Part 3

Disassembled dual stick assembly and deburred stick holes. Lubricated control stick horns with lithium grease and deburred taper pin holes. Reassembled left and right control sticks and attached link rod with hardware. C04 complete! Hours Worked: 0.70

-

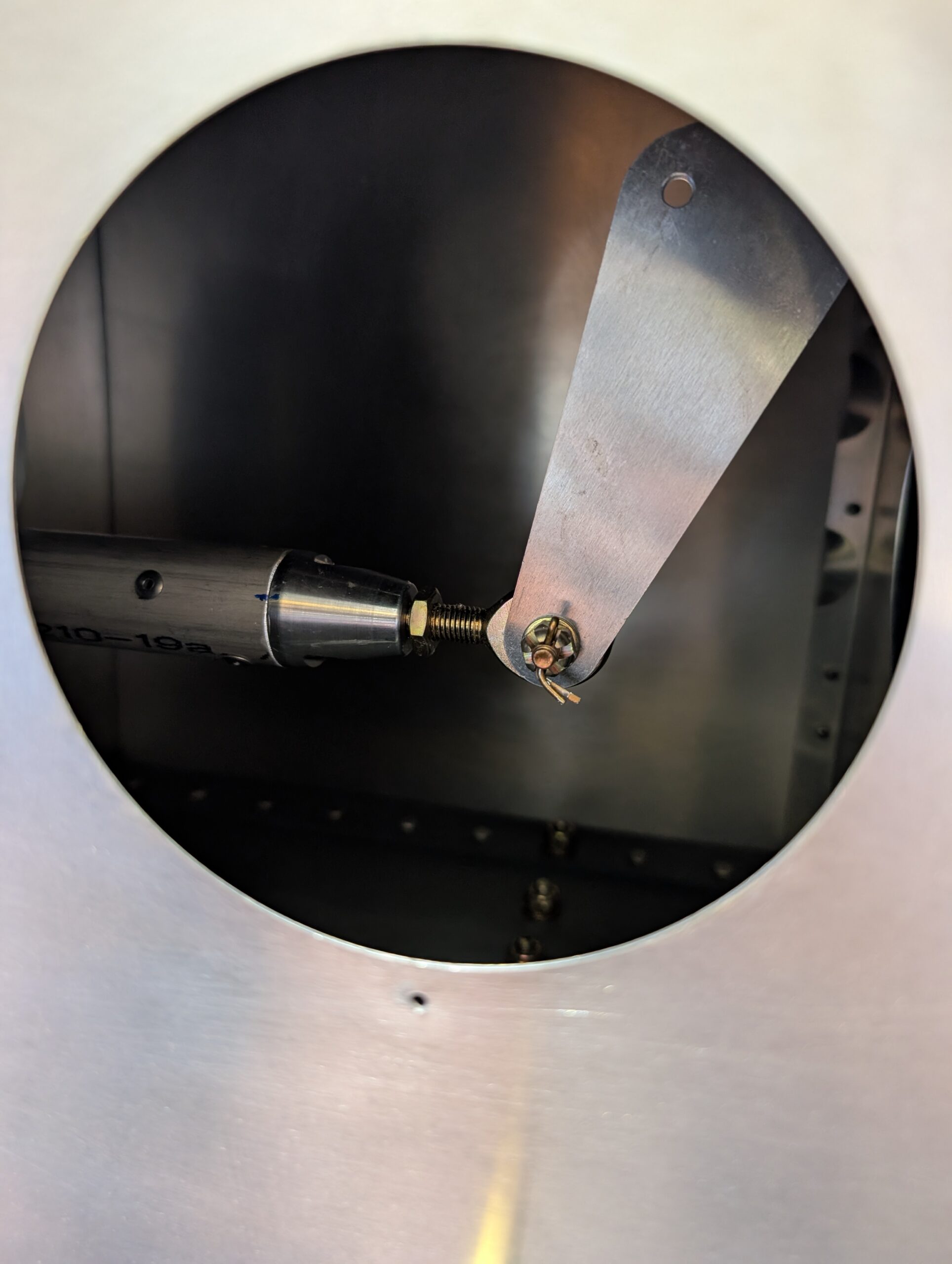

Wing Pushrod Installation – Part 1

Removed aileron bellcrank access covers from wings and inserted C03-01 main aileron pushrods into wings. Attached to aileron bellcrank with AN3 hardware and castle nut. Installed C03-03 flap pushrods onto flaps with AN4 hardware. Hours Worked: 0.98

-

Tailwheel Installation – Part 2

Deburred tail wheel and spring holes and installed AN4 hardware through tail wheel assembly. Reinstalled clecoes on aft fuselage floor and took off of saw horses. Rolling chassis complete! Hours Worked: 1.26

-

Forward Fuselage Part Prep – Part 2

Assembled F10-16 idler assembly (skipping -21 and -17 sub assemblies. Used vice to press in Symmco bushings to pivot angles. Lubricated bushings and pivot bearings with LPS-2 prior to assembly. Hours Worked: 0.57

-

Aileron Bellcranks – Part 4

Drilling of holes in -13L/R and -14L/R vertical channels. Both -10 bell crank assemblies created. Two washers per assembly needed to get castle nut aligned properly. Completed -01L including final riveting and lubrication of pivot with white lithium grease. -08 clip heights on vertical stiffeners set by using right angle from rib face. -01R clecoed…