-

Aft Forward Fuselage Assembly – Part 1

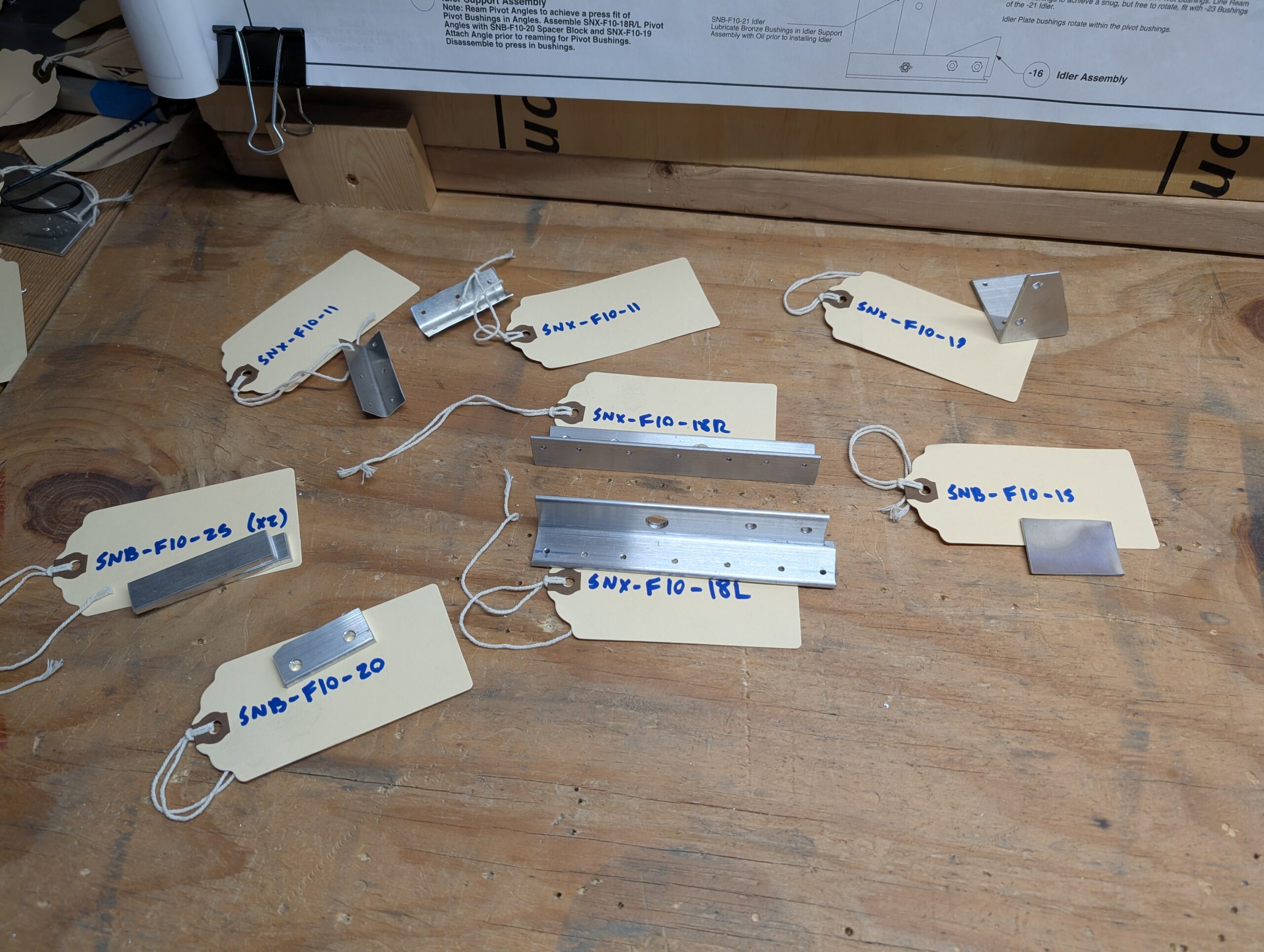

Following general construction order on plans, assembled -02 seat belt assembly and riveted. Fist assembly to fuselage and temporarily clecoed F10-02 angle to assembly to ensure straightness. Pilot drilled and clecoed assembly to side panels and floor. Determined SNB-F10-25 gusset…

-

Forward Fuselage Assembly – Part 6

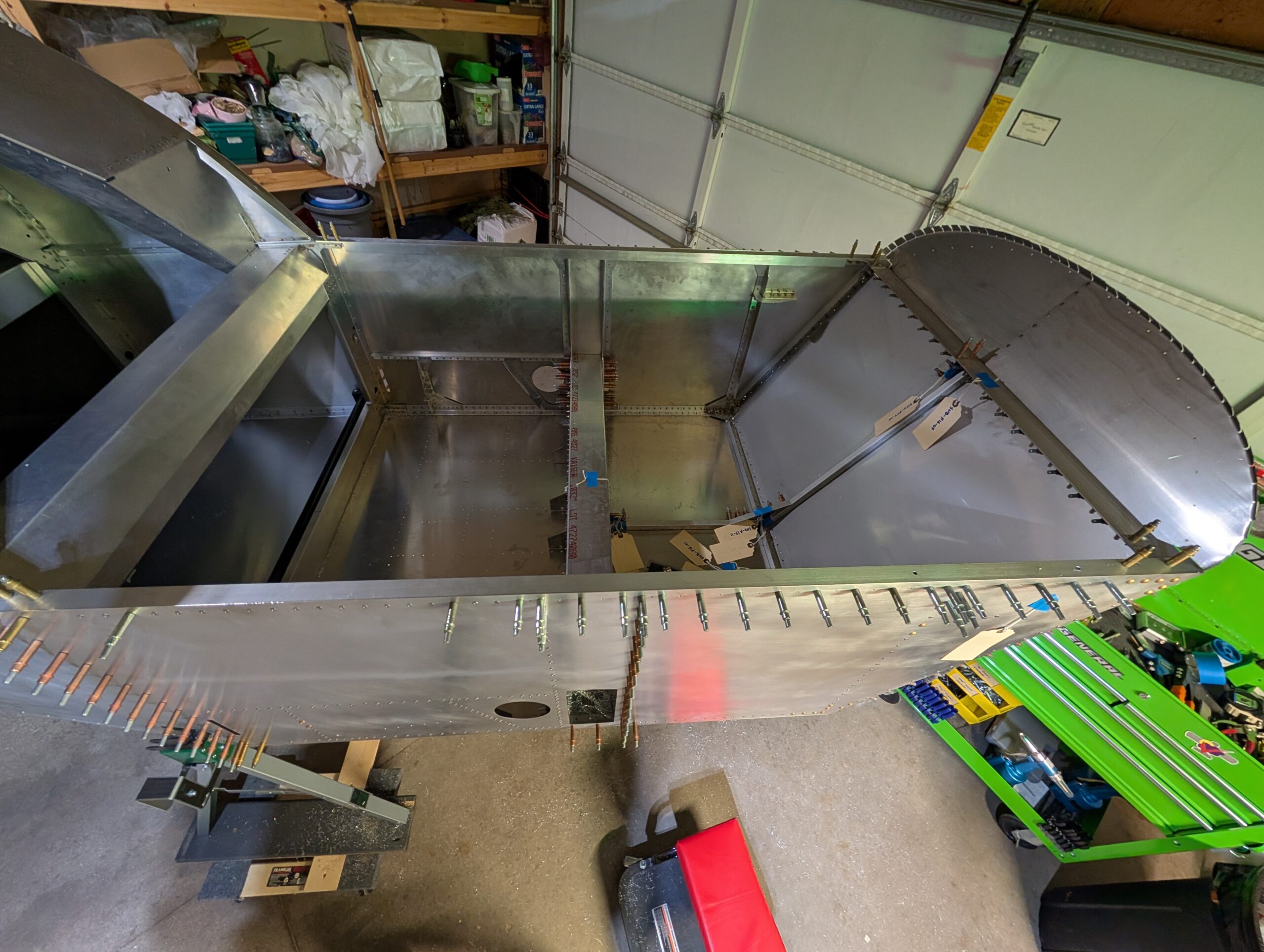

Clecoed lower floor/firewall stiffener and floor stiffener into place. Deburred upper firewall and riveted to fuselage box. Deburred forward fuselage floor and clecoed into place. Will wait until very end to rivet floor into place. F11 complete! Hours Worked: 1.42

-

Forward Fuselage Assembly – Part 5

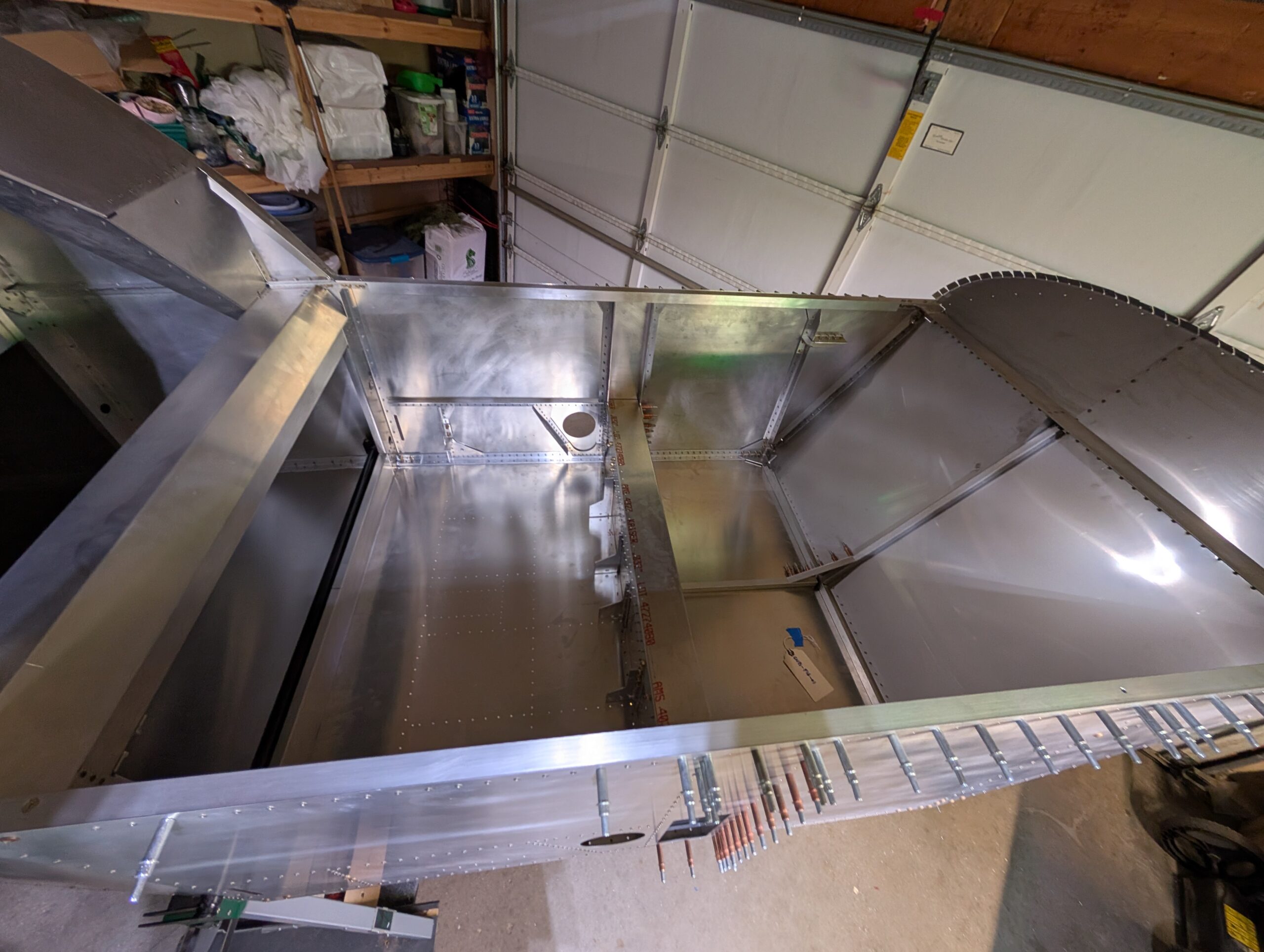

Deburred LH and RH fuselage side panels and countersunk wing mount angle holes then re-clecoed into place onto fuselage. Deburred, dimpled, and countersunk aft spar tunnel web and clecoed back onto side panels as separate pieces. Riveted aft spar tunnel…

-

Cowl Hinges – Part 1

Creation of -08 Hinge Half from P3 piano hinge stock. Hours Worked: 0.33

-

Forward Fuselage Assembly – Part 4

Up drilled LH fuselage side skins and splice plates. Countersunk top longeron for flush hardware. Up drilled forward fuselage floor including bolt holes. Aligned P13-08 lower cowl hinge half then drilled and clecoed to lower firewall. Up drilled lower firewall.…

-

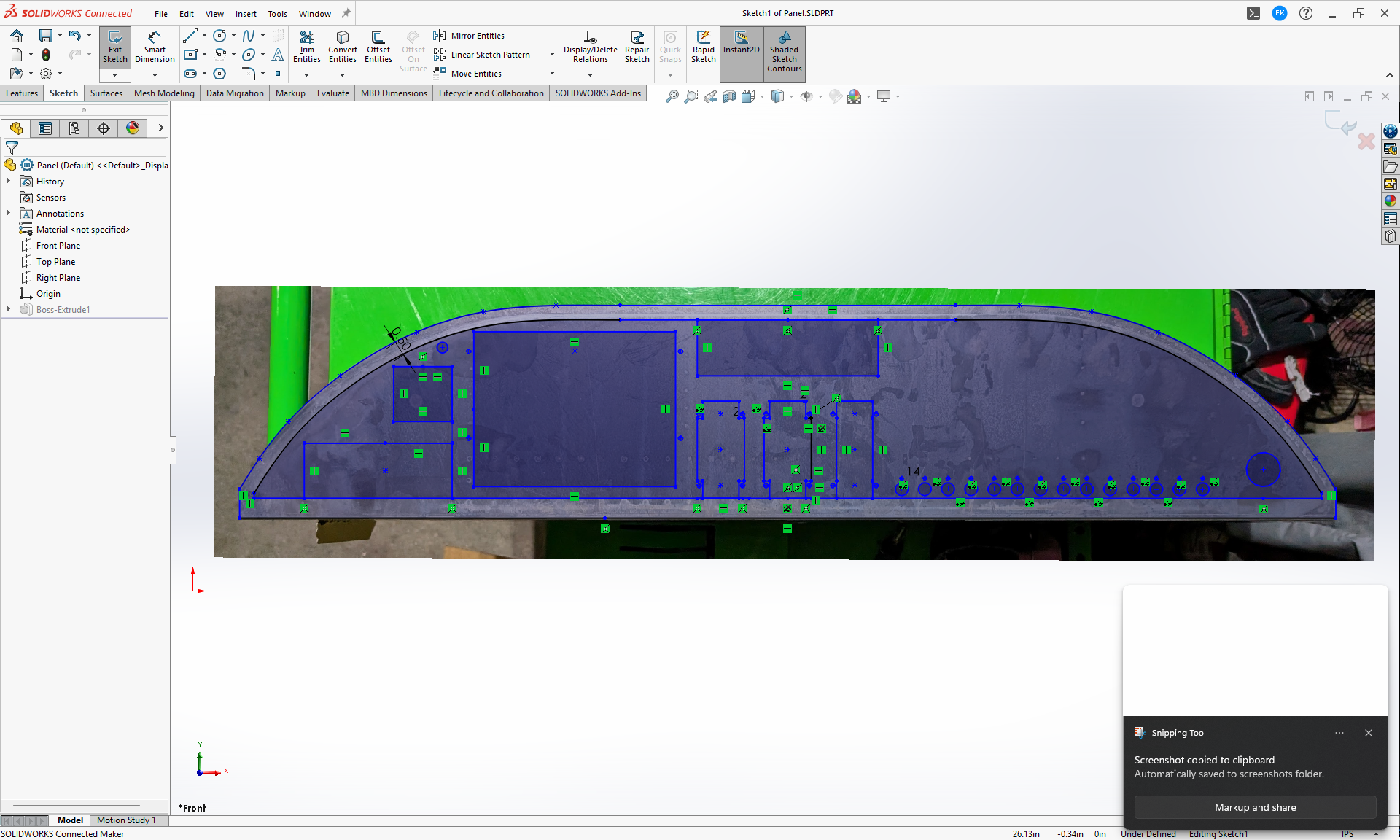

Panel Decals

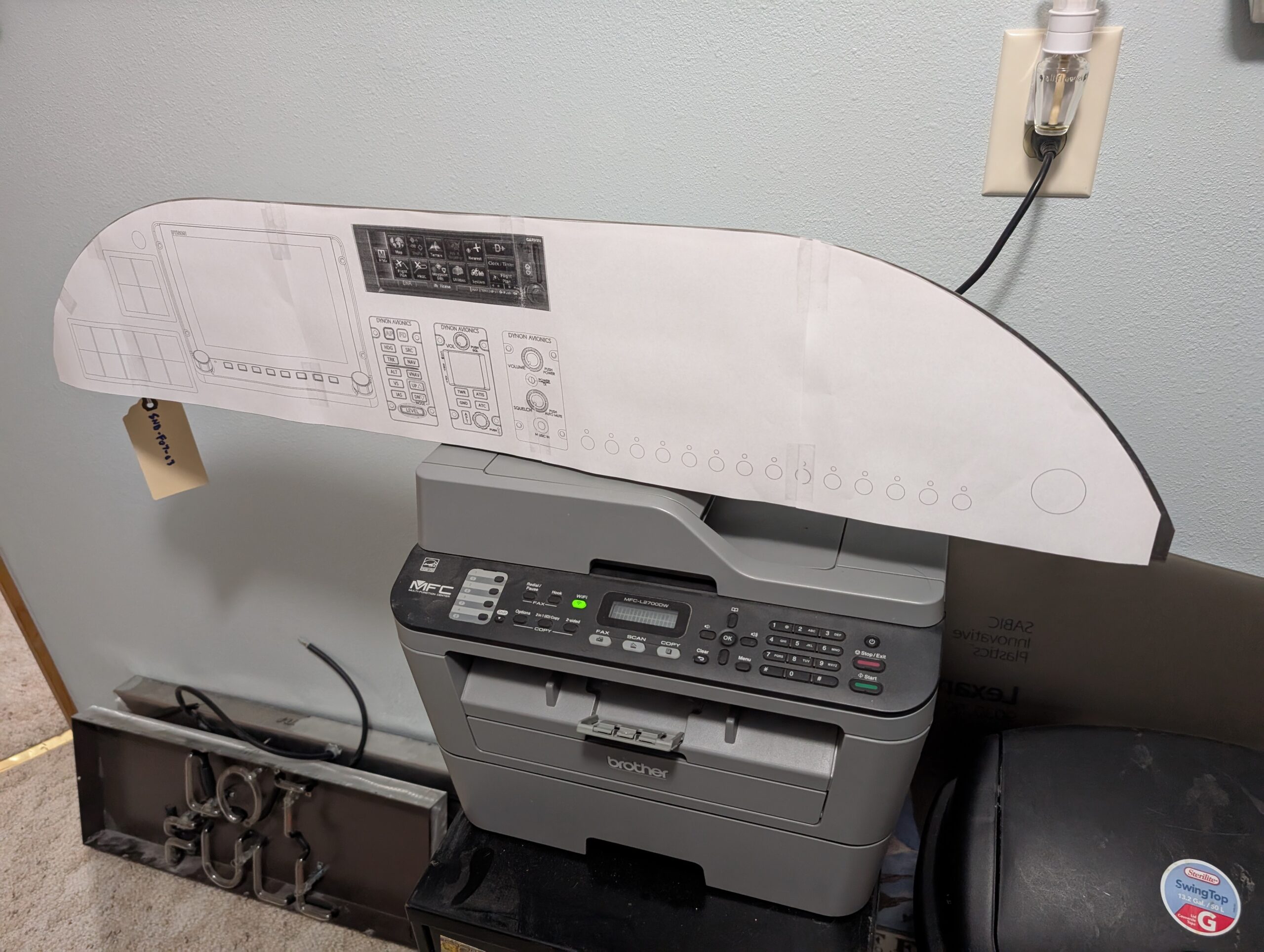

Updated CAD design to include tail number and passenger warning. Modeled trim wheel and updated dimensions for GPS175. Printed out design full scale and mocked up on actual instrument panel blank Hours Worked: 4.34

-

Forward Fuselage Assembly – Part 3

Pilot drilled and clecoed upper/lower LH/RH splice plates to forward longerons. Removed forward wing angles and clecoed forward tunnel Z and spacer plates then refitted to forward fuselage. Determined there was no way to get aft tunnel web assembly into…

-

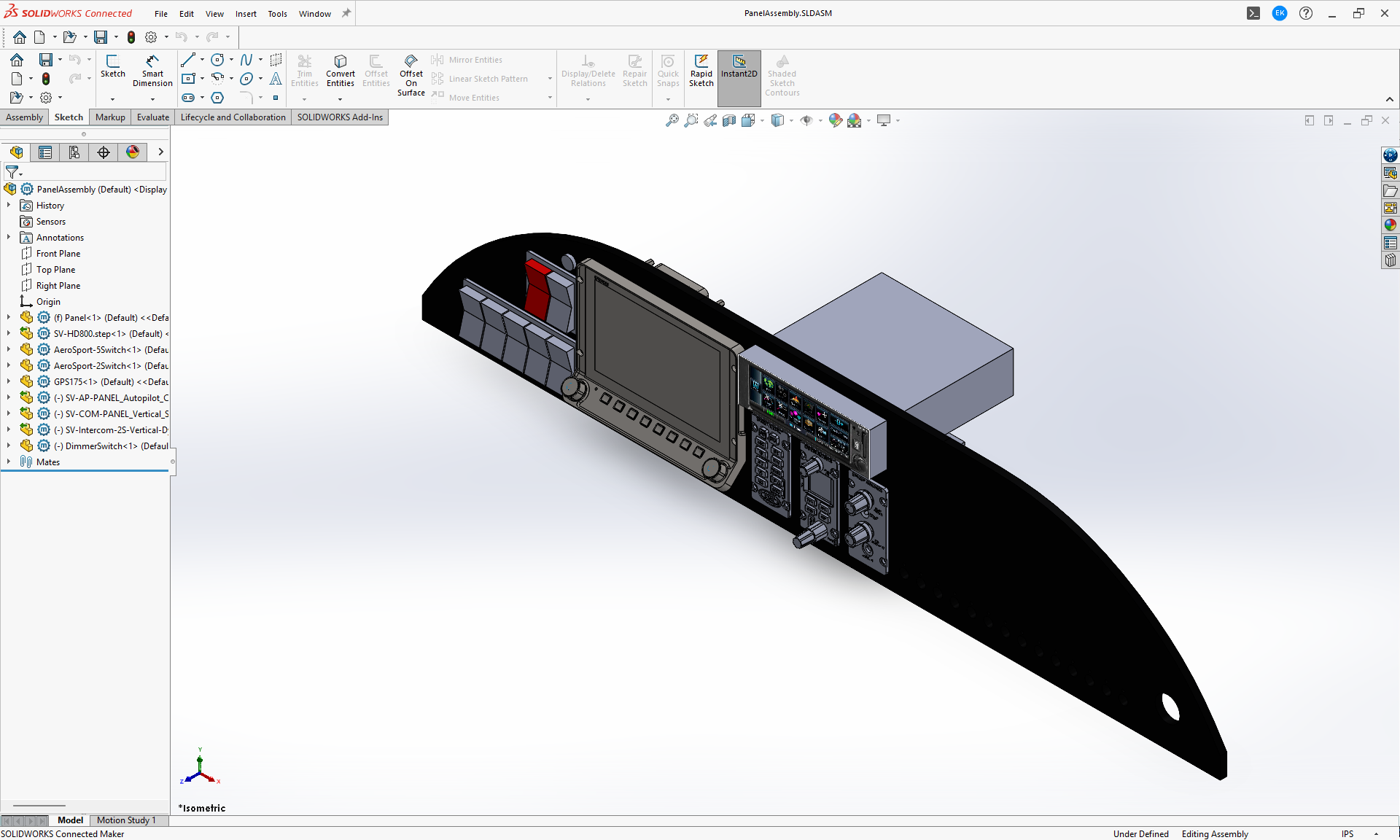

Starting to Place Components

Created assembly file and began fitting components to panel cutout in SolidWorks. Created rough model for switch panels and GPS175 and inserted to panels. Laid out cutouts for panel power, light dimmer, and circuit breakers. Need to model cutout for…

-

Forward Fuselage Assembly – Part 2

Pilot drilled bolt holes through upper and lower motor mounts, longerons, and fuselage floor. Located lower forward crosstie and pilot drilled with floor skin holes. Created jig from angle rulers to set side panel width at 40″. Fit lower firewall…

-

Creation of Panel CAD Model

Uploaded picture of panel into SolidWorks and created model of panel blank. Downloaded .STEP files of Dynon components and modeled cutouts per installation instructions. Hours Worked: 5.00

-

Forward Fuselage Assembly – Part 1

Clecoed left and right forward side panels to aft side skins. Removed clecoed from #1 lower cross tie and aft fuselage floor and aligned lower forward skin to existing holes. Clecoed forward and aft fuselage floors to cross tie then…