-

RH Aileron Inspection

Inventory of RH Aileron previous work. Hours Worked: 0.73

-

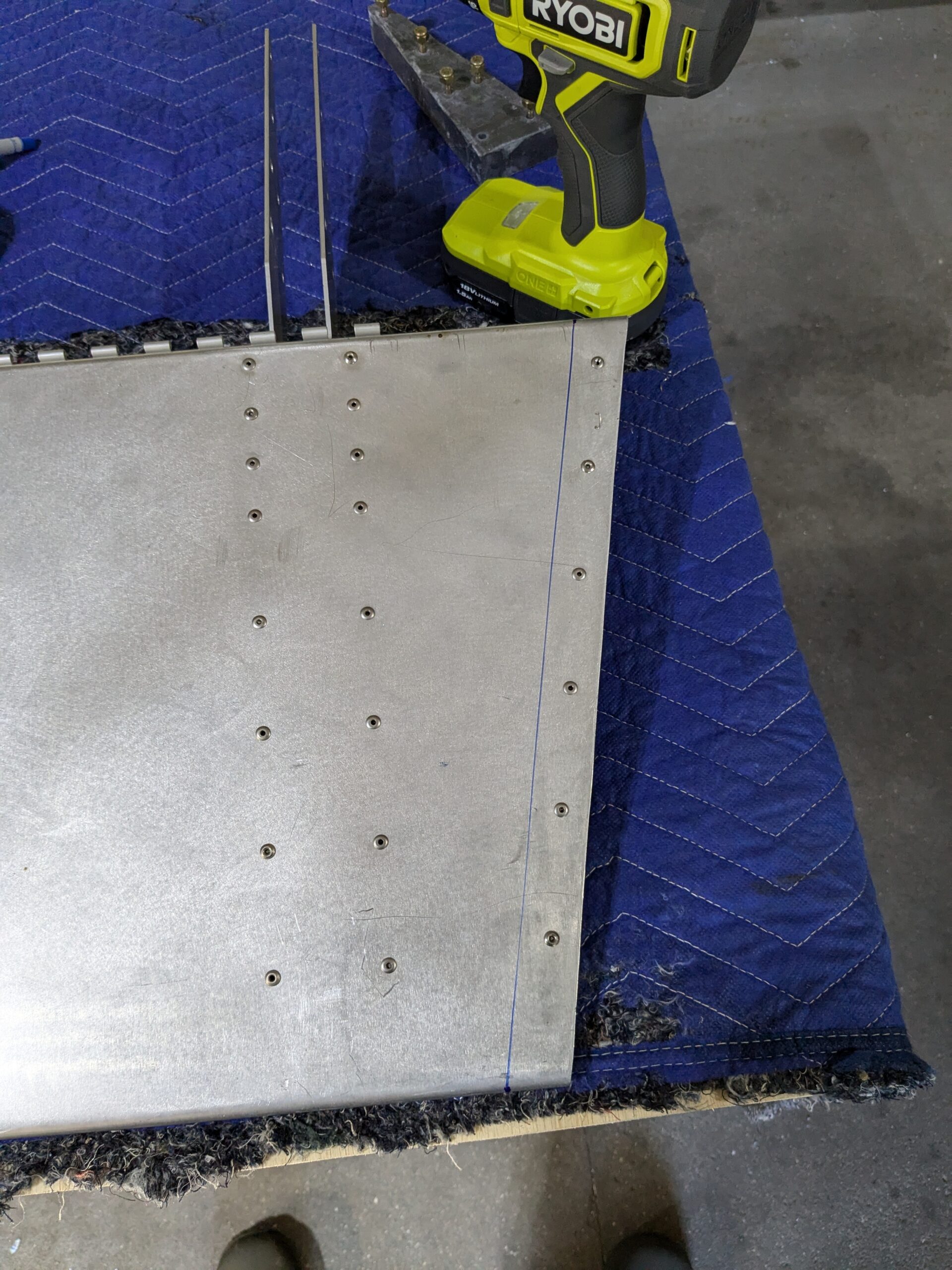

Aileron Hinge Replacement

Examined RH aileron assembly. Determined that aileron hinge half was not to plan and was improperly aligned with top edge. Drilled out hinge half and replaced with new hinge using strap duplicator to match holes. Leveled assembly on work bench…

-

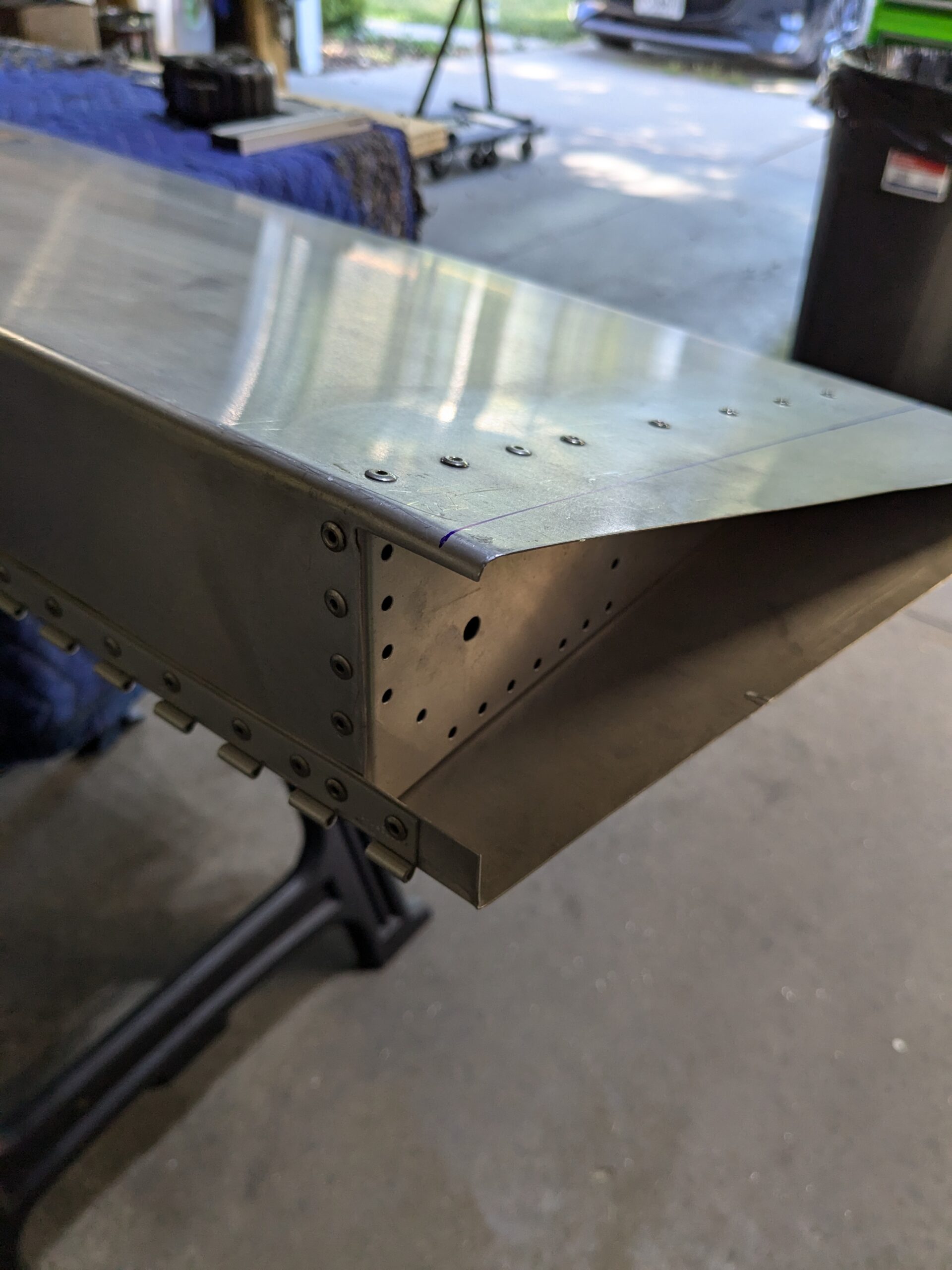

Aileron Correction

Inspected previously assembled ailerons. Noted that the overall width of existing ailerons is larger than plans called for. Drilled out rivets in tip rib and trimmed skin to proper dimensions. Removed lead counterweights from ailerons and tested fit with wings.…

-

Flap Issues

Began flap details by examining already assembled flaps. Flap drive plate needs to be replaced per wing conversion instructions. Upon removing legacy version flap drive plate, noticed holes do not line up and inboard-most rib location is different between the…

-

LH Landing Light – Part 4

Protected LH landing light lens with painter’s tape and fit into opening. Trimmed lens per instructions, cleaned up all edges with rotary tool, and installed lower retaining strip with double-sided tape and packing tape. Felt strip installed around landing light…

-

LH Wing Assembly – Part 12

Finished riveting lower side of LH wing including aft and forward skins. Installed aileron bell crank inspection cover plate using PK screws. LH wing complete! Hours Worked: 1.33

-

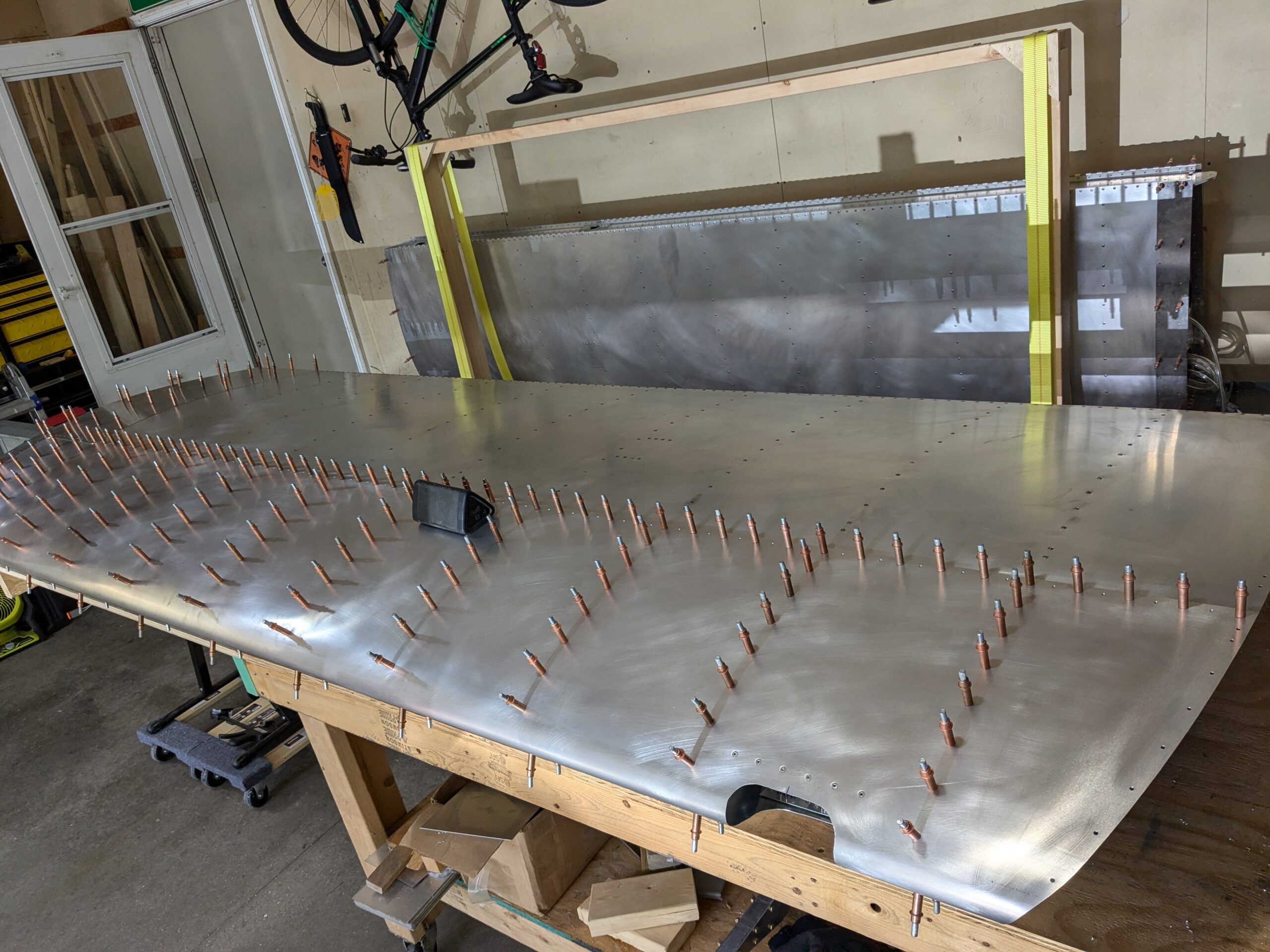

LH Wing Assembly – Part 11

Deburred LH flap and aileron hinge halves and clecoed into place. Clecoed top of LH forward wing skin into place then flipped wing and ratcheted lower side into place. LH root doubler clecoed into place on top. Clecoed lower side…

-

LH Wing Wiring

Drilled passthrough hole in LH tip web and installed Heyco 2030 snap busing. Installed left wing wiring harness for tip and landing light. Created connectors LW01 and LW02 (DT style) and wired landing light. Landing light ops check good. Wrapped…

-

LH Wing Assembly – Part 10

Deburred and cleaned aft lower and forward wing skins along with root doubler. Tiedown hole in lower skin up drilled to 3/4″ per plans. LH forward skin dimpled. Leveled LH rib assembly on workbench and reattached alignment angle between main…

-

LH Wing Assembly – Part 9

Deburred, scotchbrited, and cleaned upper wing skin with acetone. Hours Worked: 1.20

-

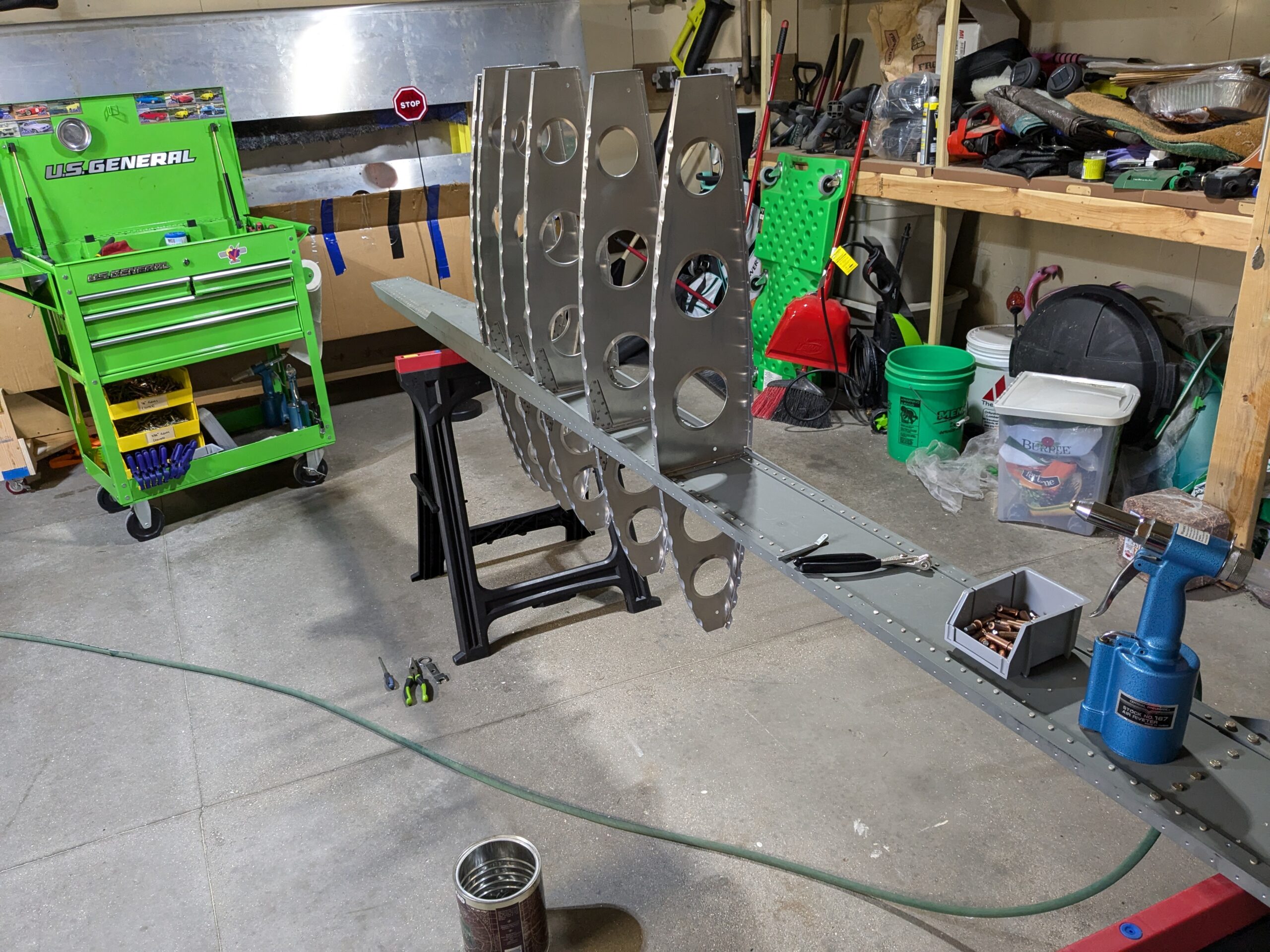

LH Wing Rib Assembly – Part 4

Completed assembly of LH wing rib installation by prepping and riveting forward and aft ribs #6 – #12. Rear spar deburred, cleaned, and riveted to rib assembly. LH aft root rib riveted to rear spar. Hours Worked: 3.49

-

LH Wing Rib Assembly – Part 3

Attached W17-01L assembly to main spar. Bolt direction altered from plans to account for rivet interference. Starting inboard and working outboard, attached forward and aft ribs 1-5 to main spar and riveted into place. Forward ribs scotchbrited, acetoned, deburred, and…