Electrical

-

Avionics Sub-panel – Part 2

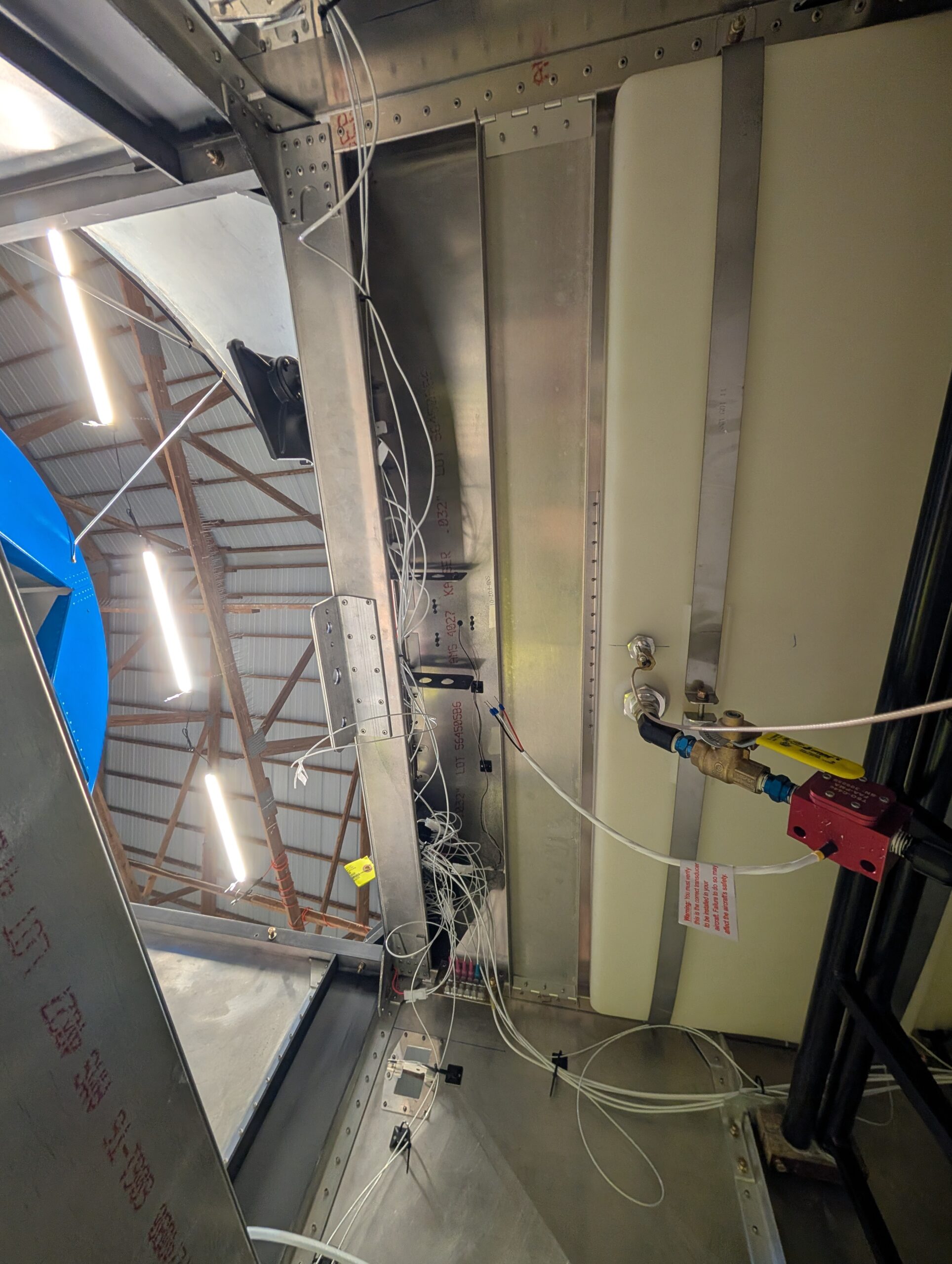

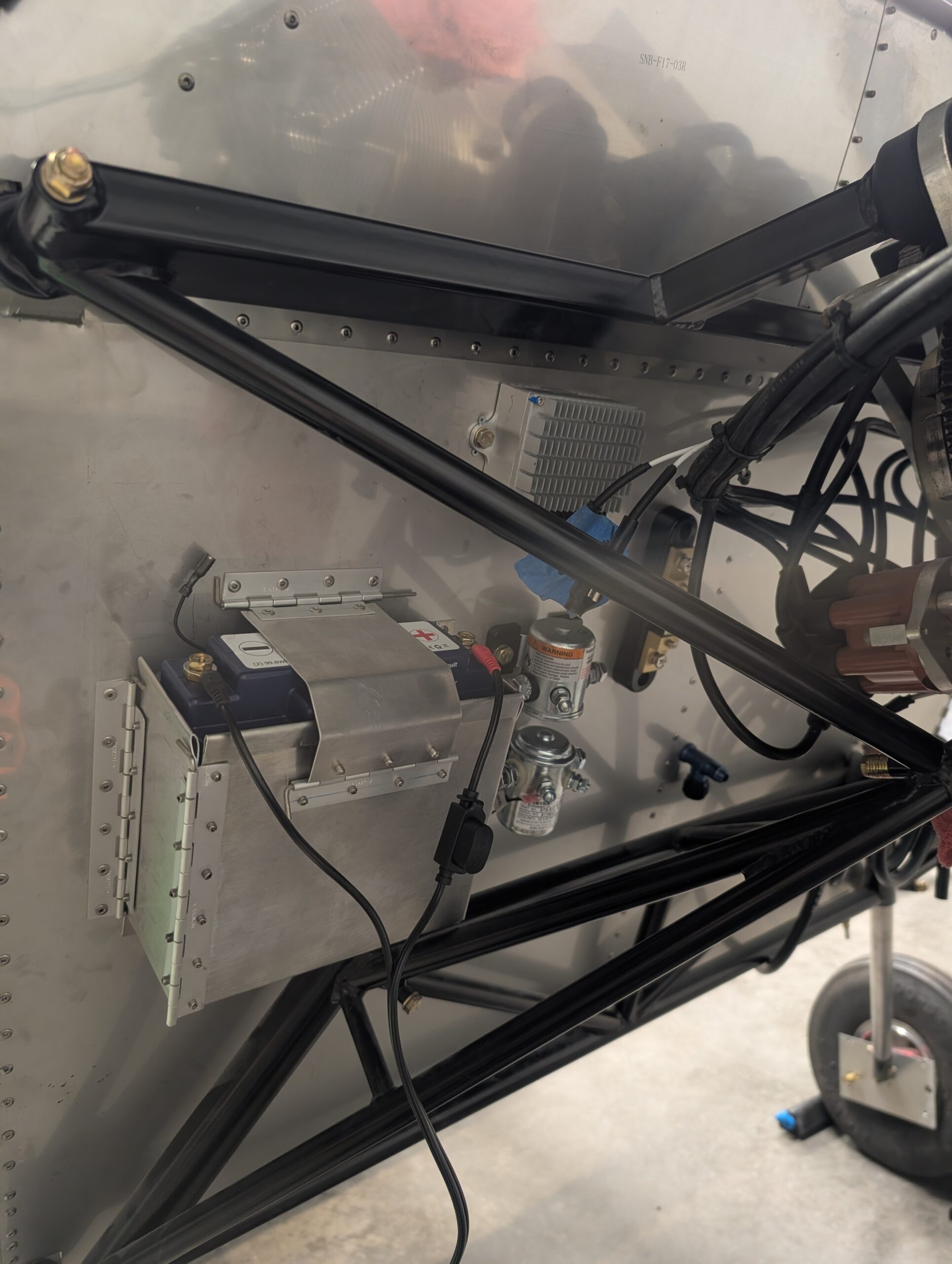

Created mount angle for EMS and ARINC module from scrap 0.032 sheet due to lack of clearance for modules with connectors on both ends. Riveted nut plates to vertical mount and then riveted mount to avionics shelf. Laid out backup battery, wig wag module, and fuel probe box onto shelf and marked mounting holes. Installed…

-

Avionics Sub-panel – Part 1

Created avionics sub-panel (shelf) from Z04-03 stock. Made mounting hinge pieces from -5 piano hinge to allow for more adjustability. Mocked up shelf locating behind panel and in front of fuel tank and pilot drilled hinges to upper longerons then to shelf. Removed assembly, updrilled hinge halves, then riveted hinge mounts to upper longerons. Riveted…

-

Circuit Breaker Wiring – Part 1

Began terminating panel wires to RH panel cover and circuit breakers. Connected master relay, master switch, and avionics switch wires to bus bars then connected available components to top of circuit breakers. Screwed RH panel cover into place onto panel backer. Should have enough room to attach future components with circuit breakers in place. Hours…

-

Circuit Breaker Mounting

Bolted Ram mount base to RH panel cover using AN3 hardware. Cut copper bus bars to size and drilled circuit breaker holes at 0.8 inch spacing. Installed circuit breakers into RH panel cover then secured bus bar onto bottom terminals of circuit breakers with 6R4 screws. Used two separate bus bars for circuit breakers; one…

-

Main Switch Panel Wiring

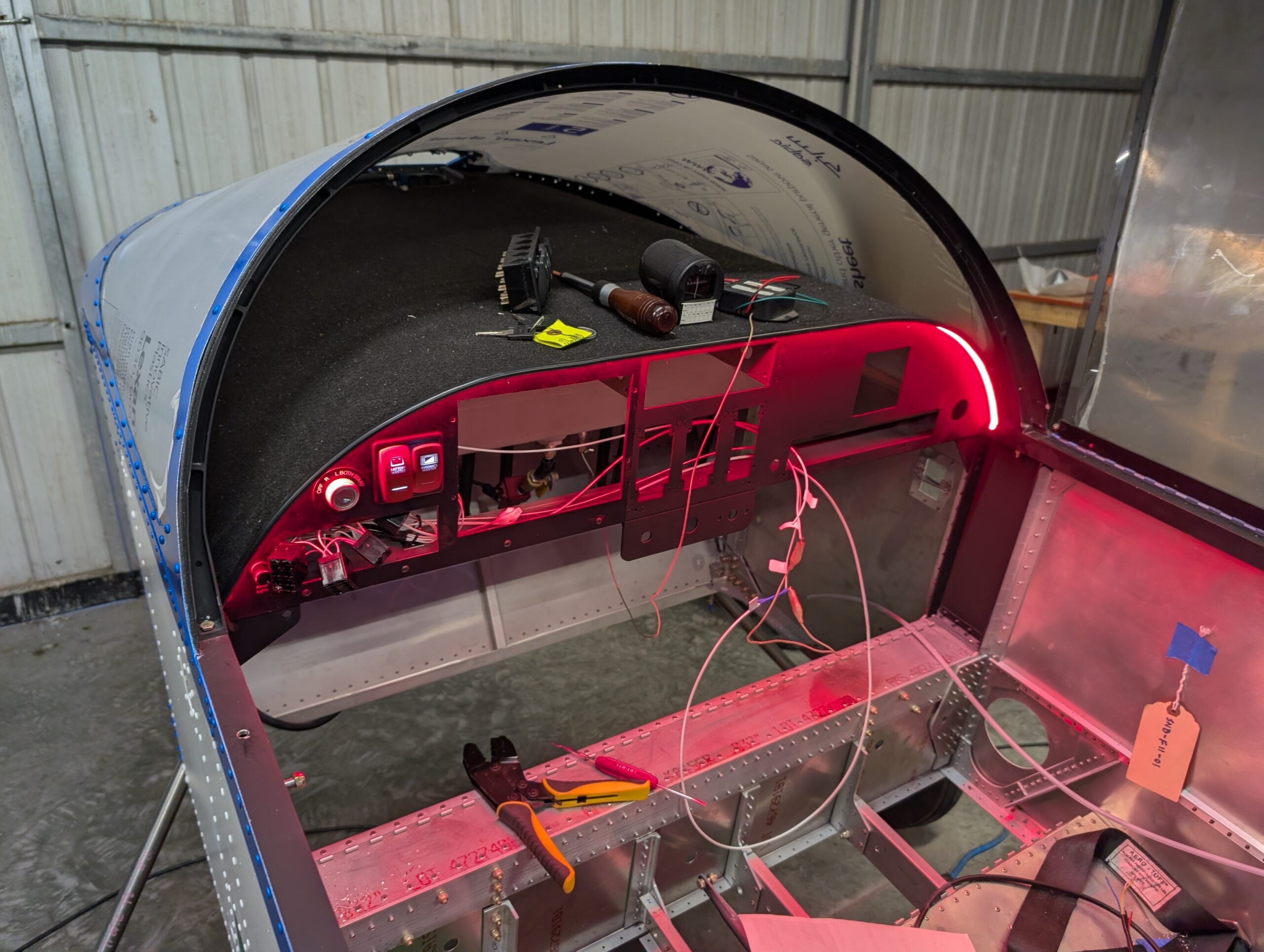

Created harnesses for main panel switches leading to circuit breaker panel and wing root connectors. Laid out wiring path for each wing root connector and placed securement points. Installed main switch panel into LH side of panel and tested panel lights. Hours Worked: 2.23

-

Panel Lights Installation

Fabricated panel lights harness for panel light dimmer using Molex connectors to save space behind panel. Opted to branch out individual harnesses for each device needed the dimmer switch rather than bundling components together. Made one extra panel light circuit in case the auto dimmers on the avionics aren’t effective. Installed dimmer switch into panel…

-

Ignition Coil Wiring

Installed LH panel onto panel backer then secured ignition switch into panel. Added solder sleeves and terminals to engine end of ignition wires then attached to engine mounts and ignition coils. Added diode to master relay and ran master relay control wire back to panel. Began wiring switch receptacles by creating daisy chains for LED…

-

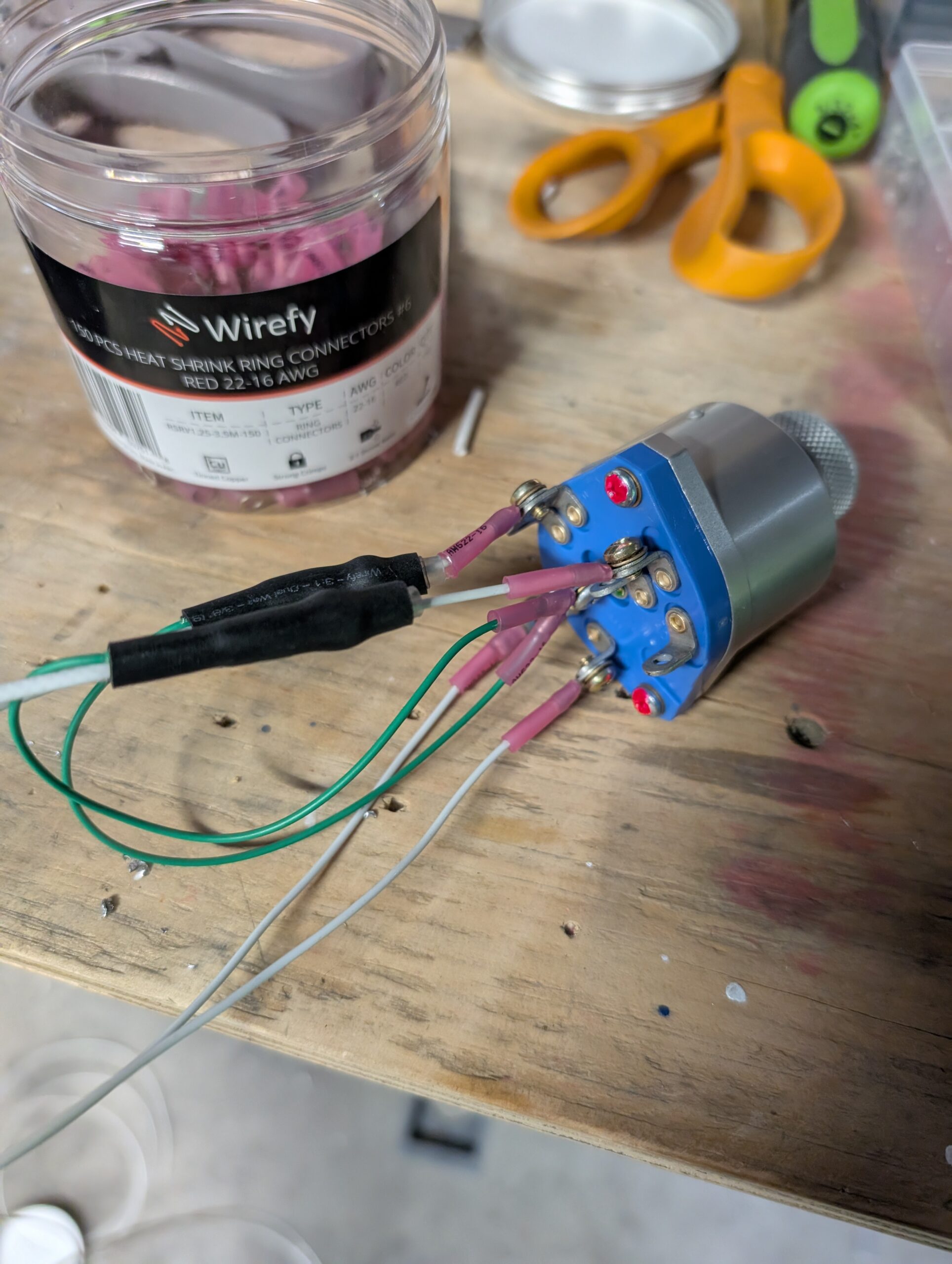

Starter Switch Wiring

Started working on ignition switch wiring harness by stripping back shielded wire for p-leads and soldering on solder sleeve to switch ends. Added terminals for switch end of wires then ran wires through firewall to ignition coils and starter relay. Will terminate ends at ignition coils in the future. Hours Worked: 1.58

-

FWF Wiring – Part 2

Replaced temporary bolts in starter solenoid with proper length bolts. Added extra bit of wire to alternator wires with solder splices and finished wiring and mounting voltage regulator and capacitor (minus the reset button). Drilled LH and RH grommet holes through firewall and clecoed gromet covers into place; will rivet when wiring is completed. Made…

-

FWF Wiring – Part 1

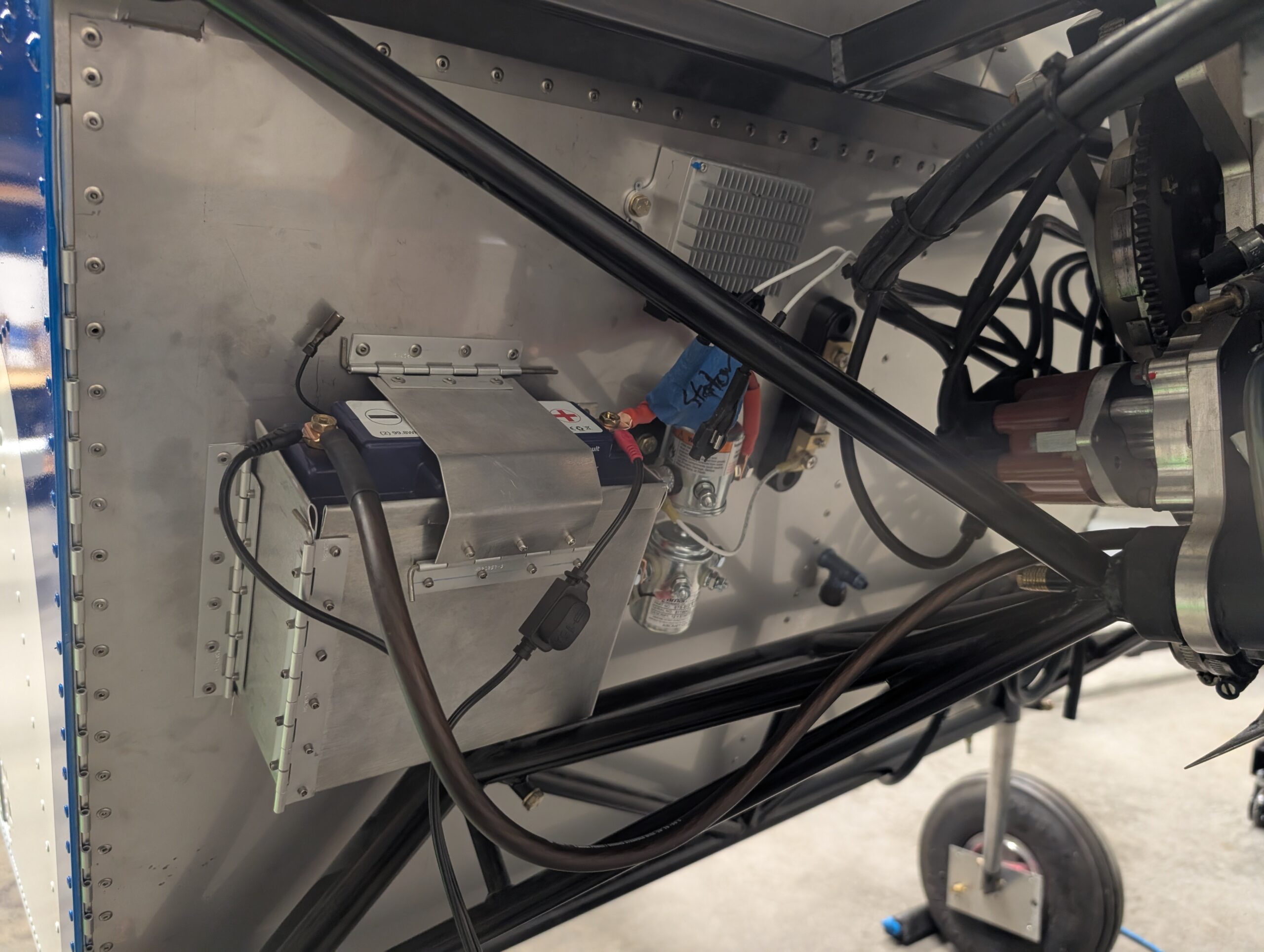

Continued working on firewall forward wiring by making battery cables for master relay, starter relay, and amp shunt. Created ground cable for engine and attached to engine mount plate bolt then secured cable to engine mount with adel clamps. Hours Worked: 2.75

-

Mounting of FWF Electrics

Began mounting FWF components on firewall by laying everything out in a logical order then marking and drilling mount holes. Installed nutplates for all fixtures to enable easy replacement in the future. Temporarily mounted starter solenoid and voltage regulator for now pending proper bolts and ring terminals for ground wires. Hours Worked: 2.87

-

Compass Mount Prep

Removed GPS175 tray from panel for better access. Marked out alignment guides on glareshield for compass. Pilot drilled holes using compass as template then updrilled for #6 screws. Used nut plate drill guide to drill nutplate mounting holes. Deburred holes and installed nutplates. Drilled 1/4″ hole in center of layout and installed rubber grommet for…