AN960-10

-

Circuit Breaker Mounting

Bolted Ram mount base to RH panel cover using AN3 hardware. Cut copper bus bars to size and drilled circuit breaker holes at 0.8 inch spacing. Installed circuit breakers into RH panel cover then secured bus bar onto bottom terminals of circuit breakers with 6R4 screws. Used two separate bus bars for circuit breakers; one…

-

FWF Wiring – Part 2

Replaced temporary bolts in starter solenoid with proper length bolts. Added extra bit of wire to alternator wires with solder splices and finished wiring and mounting voltage regulator and capacitor (minus the reset button). Drilled LH and RH grommet holes through firewall and clecoed gromet covers into place; will rivet when wiring is completed. Made…

-

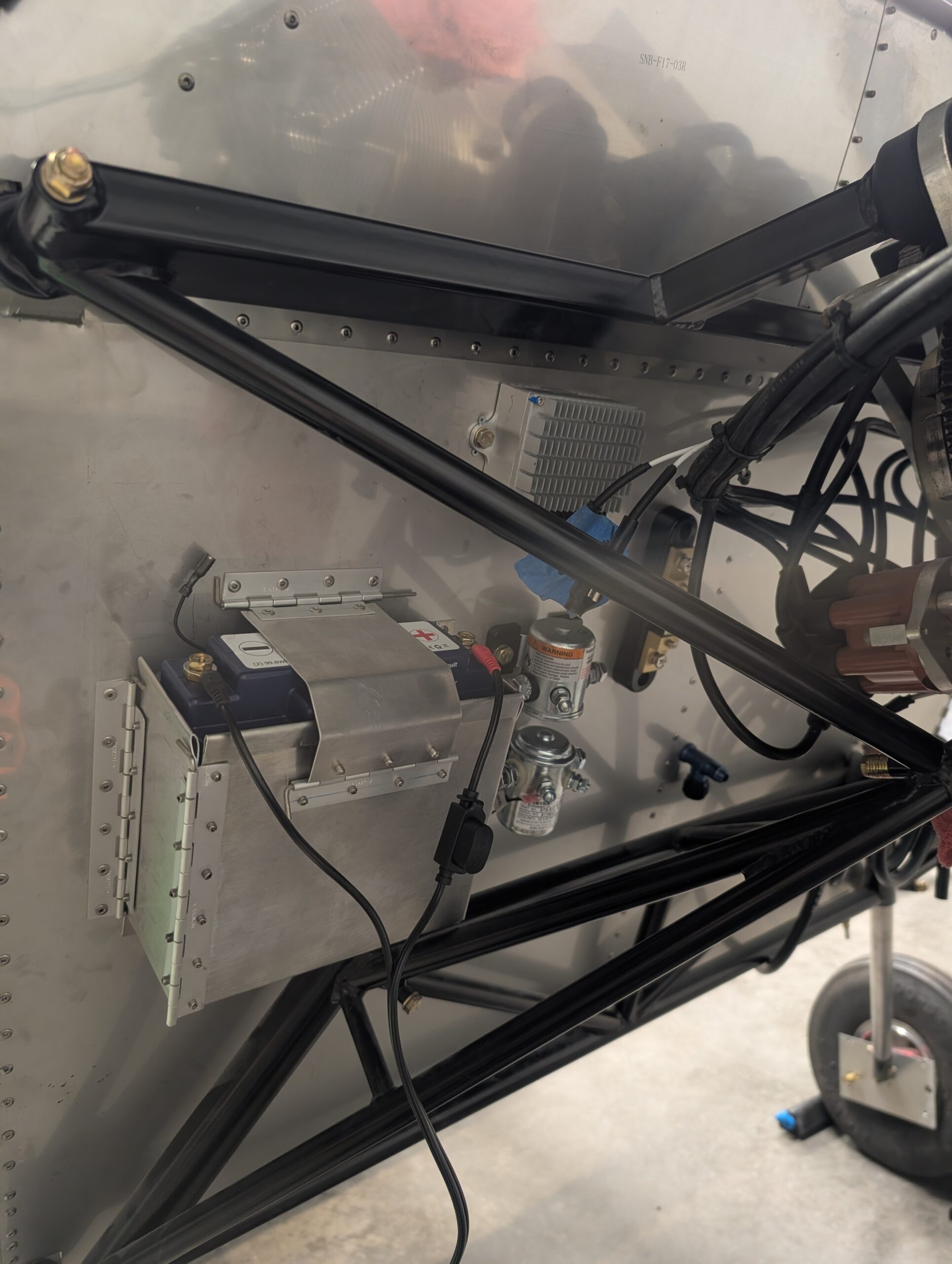

Mounting of FWF Electrics

Began mounting FWF components on firewall by laying everything out in a logical order then marking and drilling mount holes. Installed nutplates for all fixtures to enable easy replacement in the future. Temporarily mounted starter solenoid and voltage regulator for now pending proper bolts and ring terminals for ground wires. Hours Worked: 2.87

-

Canopy Installation – Part 3

Reattached canopy to fuselage with hinge pin and verified fitment along front and rear edges along with latch operation. Installed canopy retaining strap and tested operation. Located hole for canopy latch pin and drilled into upper longeron. Will remove plastic from inside and outside of canopy once aircraft is complete. Canopy task now complete! Hours…

-

Canopy Trimming – Part 3

Continued to trim and fit canopy. Matched drilled final holes in LH side of forward and aft canopy bows and realized that canopy was pulling up the frame in the front by about 1/4″. Unbolted front left corner of canopy frame and added 1/8″ spacer to lengthen the front bow area. Also added rubber washers…

-

Windshield Installation – Part 6

Finished installing windshield onto fuselage by installing screws from front to back, skipping last bottom screw on each side. Aligned windshield bow with top center screw and installed sandwiching strap in between. Needed to run tap through each screw hole to clean paint out of threads; should have done before installing bow, however. Worked from…

-

Windshield Installation – Part 5

Using two people, reinstalled bolts in upper longerons, windshield skirt, and upper motor mounts. Applied torque check to bolts to monitor torque. Slid windshield into place and began installing bolts starting from forward center and working backwards. Used a piece of tape on wrench to prevent nut from falling out. Hours Worked: 1.95

-

Rudder Control System – Part 2

Heated up C01-03 rudder spring stock with propane torch and bent springs to specs in plans. Previously tried to bend springs without heat and spring steel broke rather than bent. After installing springs into fuselage, discovered that plan dimensions were a little long and resulted in rudder pedals not returning to neutral. Shortened springs by…

-

Rudder Control System – Part 1

Installed rudder pedals and mount blocks into fuselage. Applied white lithium grease to rudder pedals before tightening rudder pedal mount blocks. Fed rudder cables through aft fuselage and temporarily installed AN23 clevis pins into rudder horn. Installed cable fairleads into fairlead blocks. Bolted cable adjusters onto rudder pedals and marked LH cable adjuster hole per…

-

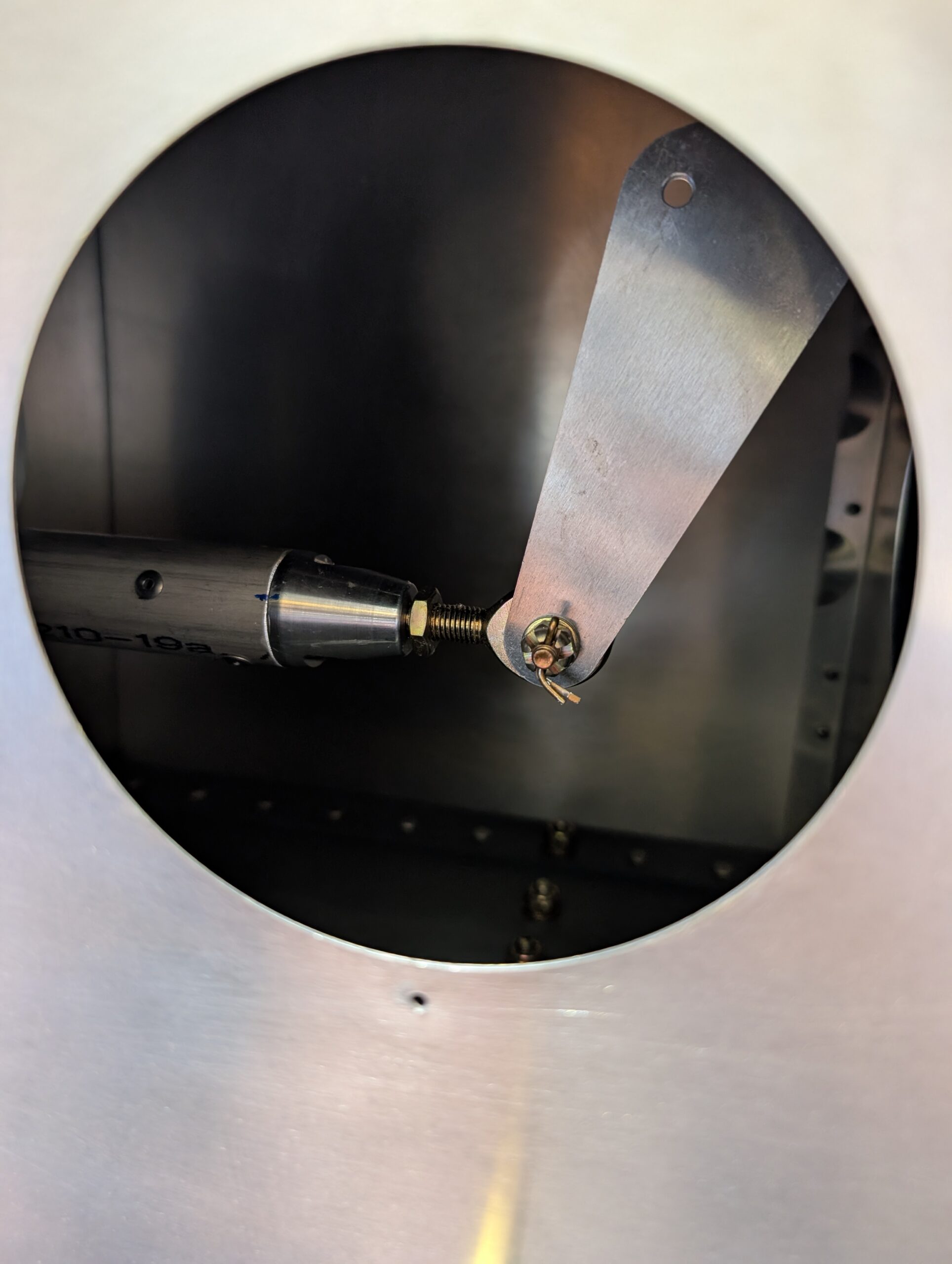

Control Stick Assembly – Part 3

Disassembled dual stick assembly and deburred stick holes. Lubricated control stick horns with lithium grease and deburred taper pin holes. Reassembled left and right control sticks and attached link rod with hardware. C04 complete! Hours Worked: 0.70

-

Wing Pushrod Installation – Part 1

Removed aileron bellcrank access covers from wings and inserted C03-01 main aileron pushrods into wings. Attached to aileron bellcrank with AN3 hardware and castle nut. Installed C03-03 flap pushrods onto flaps with AN4 hardware. Hours Worked: 0.98

-

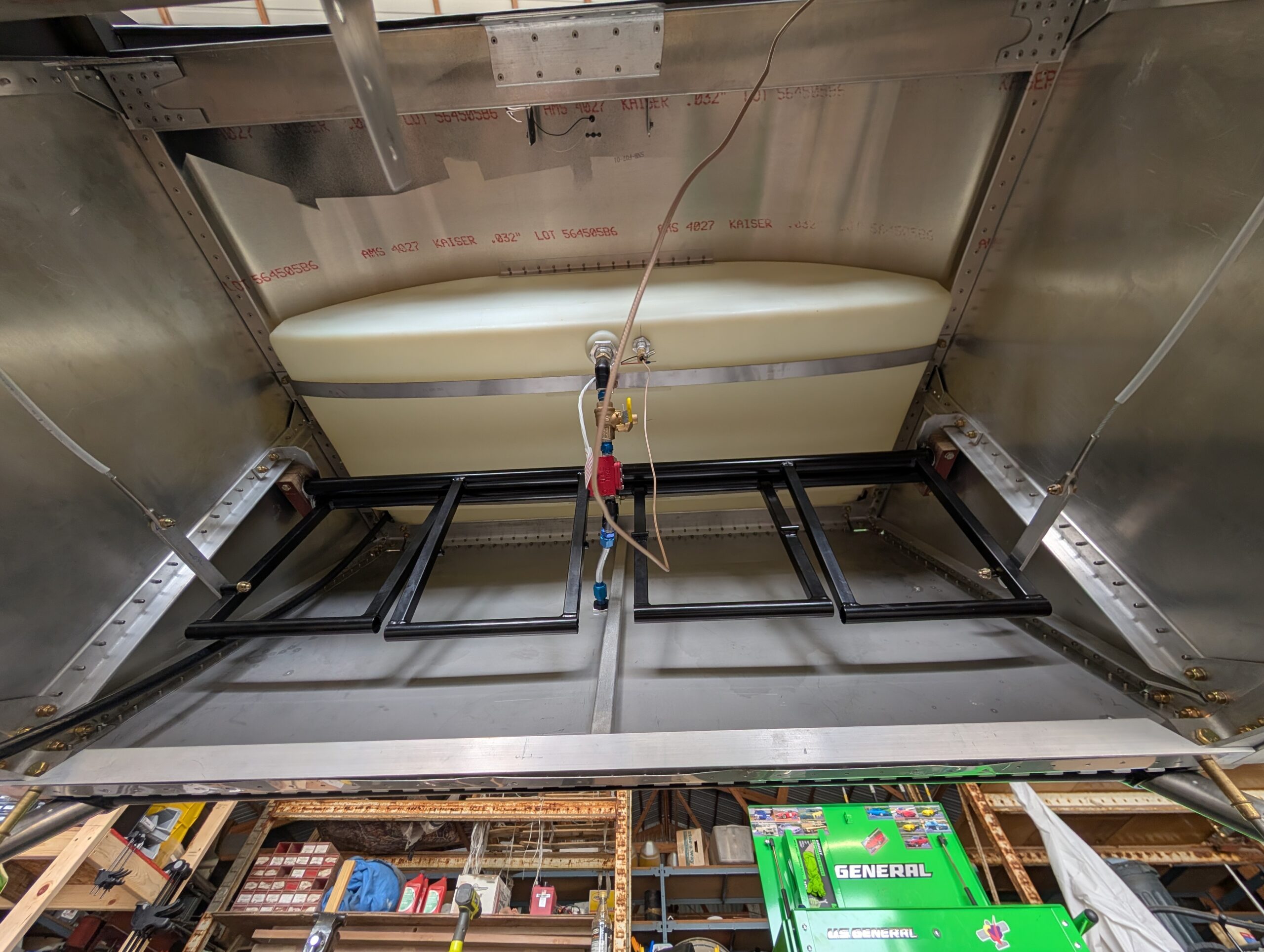

Tail Installation – Part 3

Mocked up ELT location on rear shear web and marked vertical stabilizer on where skin needs to be trimmed. Removed vertical stabilizer and marked out mounting hole location on shear web. Trimmed vertical stabilizer skin and riveted ELT mount and clamps to fuselage. Painted elevator horn with spray paint. Reattached vertical stabilizer with AN3 and…