-

New Workbench and Shelf

Built a rolling shelving unit and new mobile workbench for the hangar in preparation of moving the fuselage to the hangar. Hours Worked: 5.15

-

Fuel System Plumbing – Part 2

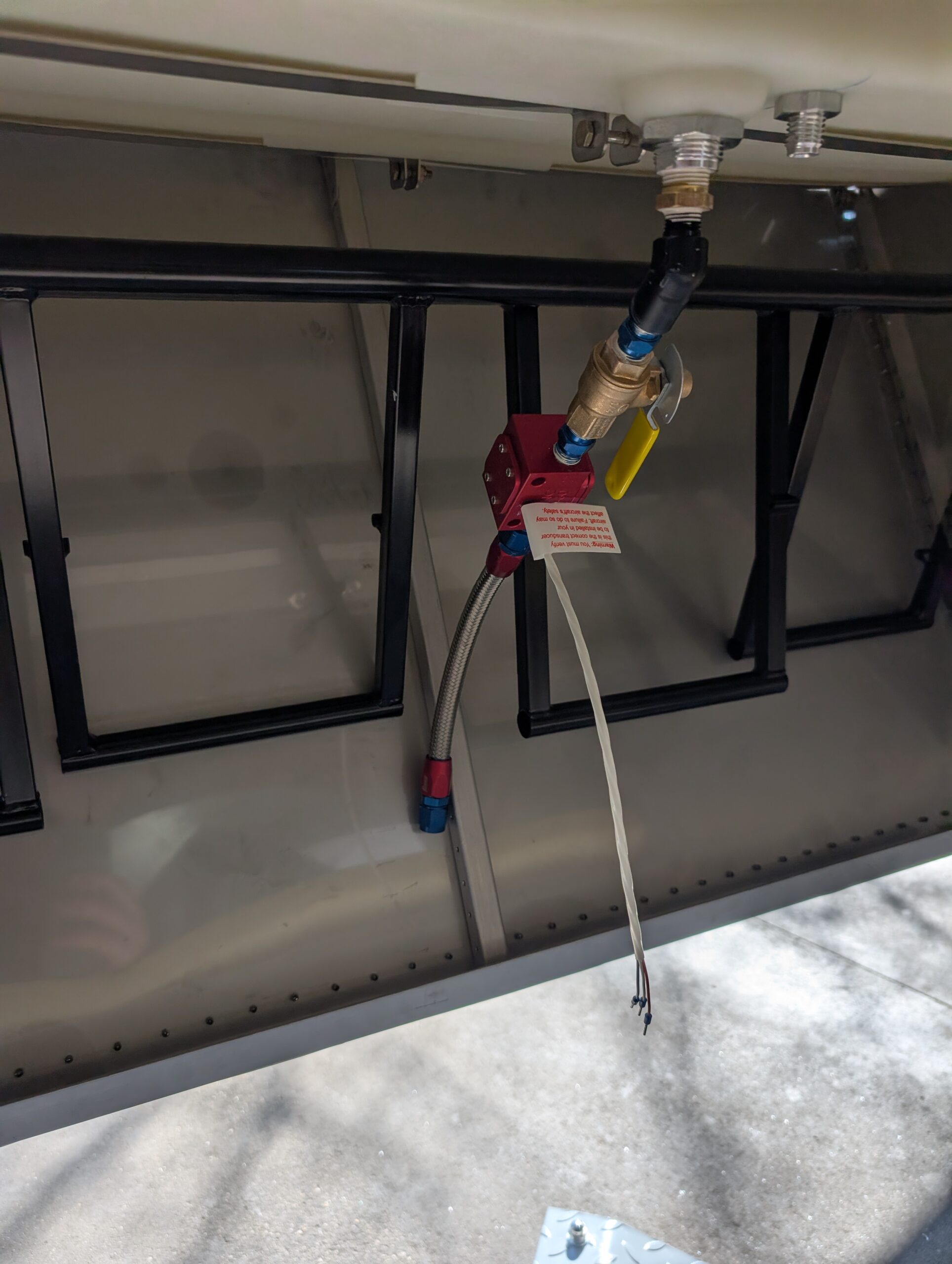

Located new bulkhead hole one inch above plans measurement to ensure continuous fuel flow. Updrilled bulkhead hole to 9/16″. Created spacer from 1/8″ aluminum scrap to go between bulkhead tee fitting and nut to keep assembly from rotating. Tried to…

-

Panel Redesign – Part 4

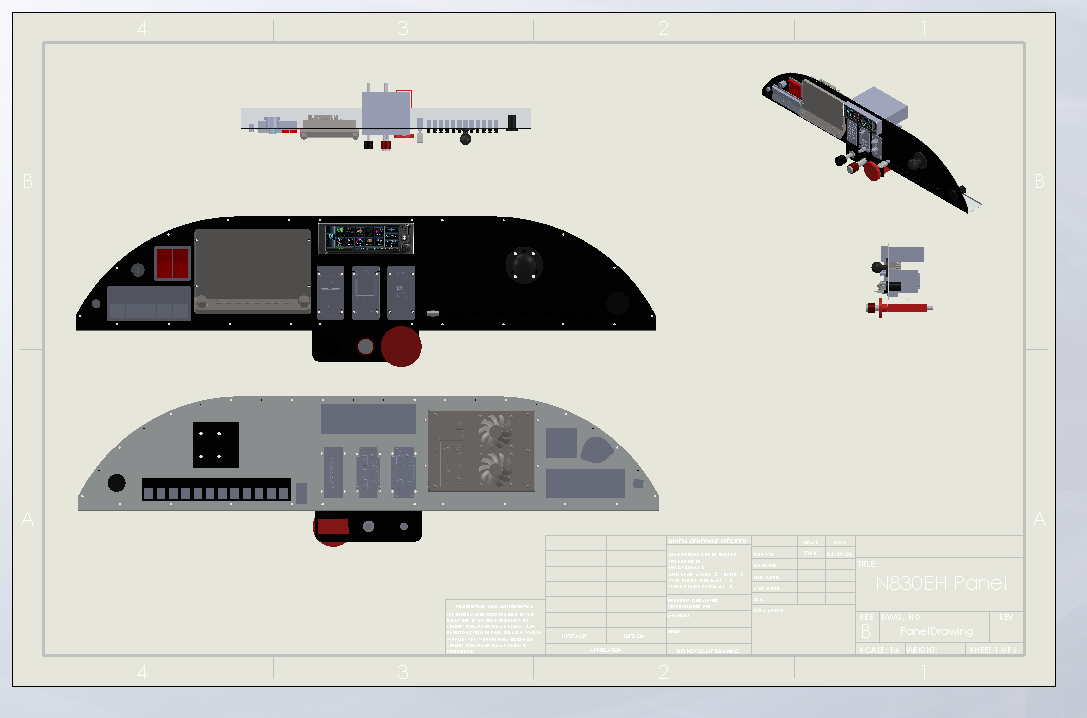

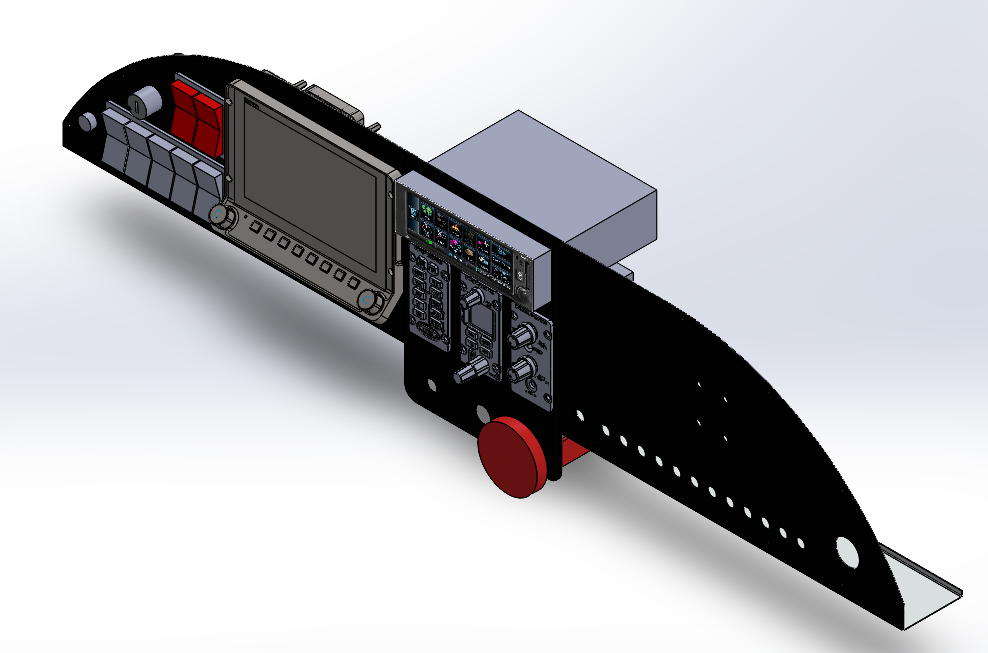

Finished designing instrument panel assembly and creating drawings to print mockups prior to manufacturing Hours Worked: 1.86

-

Fuel System Plumbing – Part 1

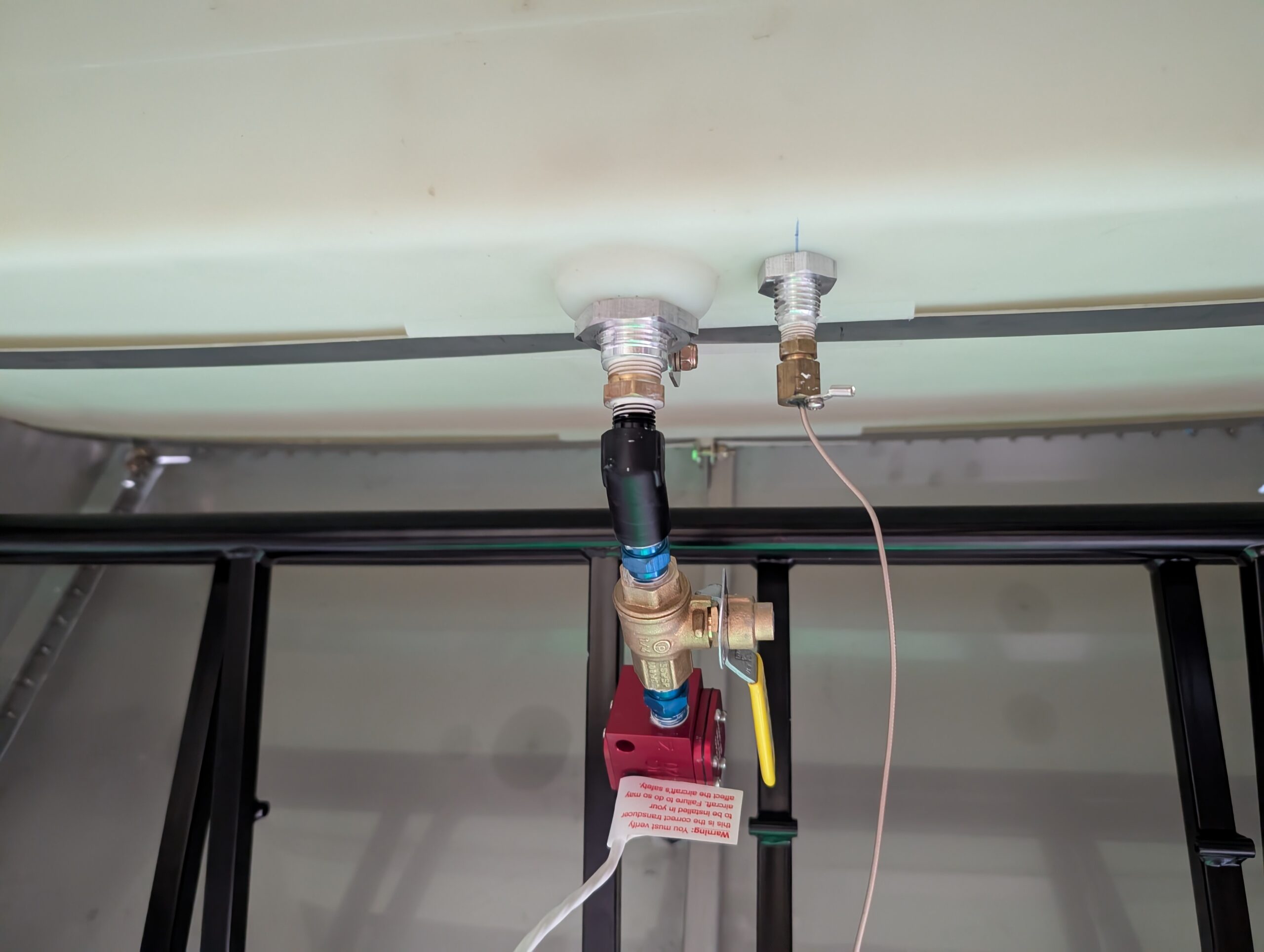

Began plumbing the fuel system starting at the fuel tank. Used liquid teflon on all NPT threads. Made short run of fuel hose to go to bulkhead fitting. Had success creating fuel line by cutting line with cable snips and…

-

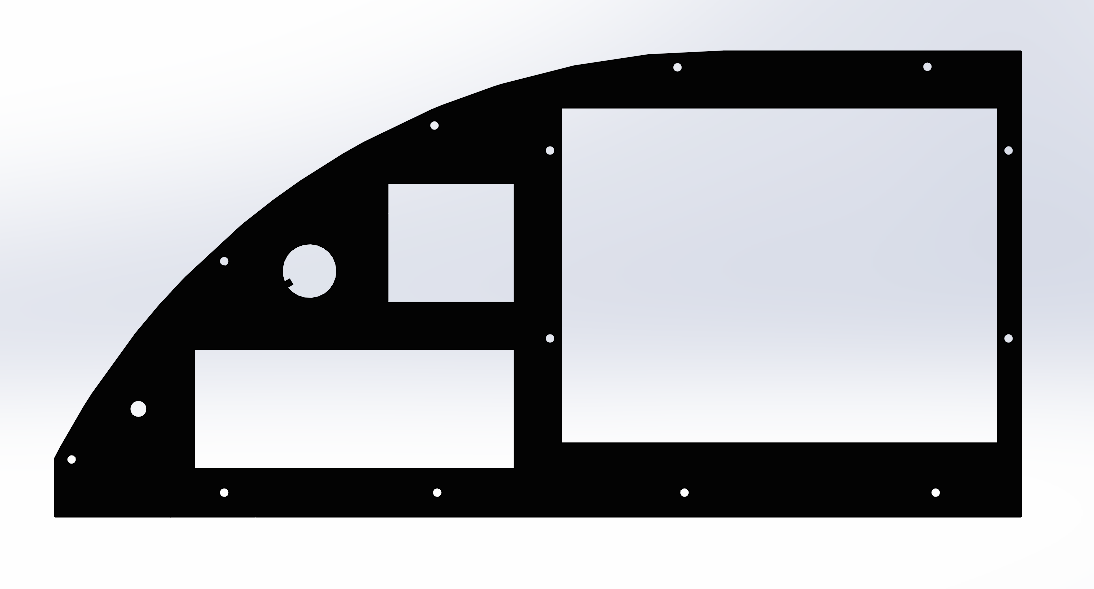

Panel Redesign – Part 3

Designed cutouts in stock panel blank to make panel cover removal easier. Began recreating assembly drawing with updated panel covers. Still need to model throttle and mixture controls along with circuit breakers Hours Worked: 2.89

-

Panel Redesign – Part 2

Started to redesign panel layout. Used most of old drawing but transferred and confirmed dimensions into new files. Split panel into three separate files to make import into Front Panel Designer easier. Opted to remove bottom features due to clearance…

-

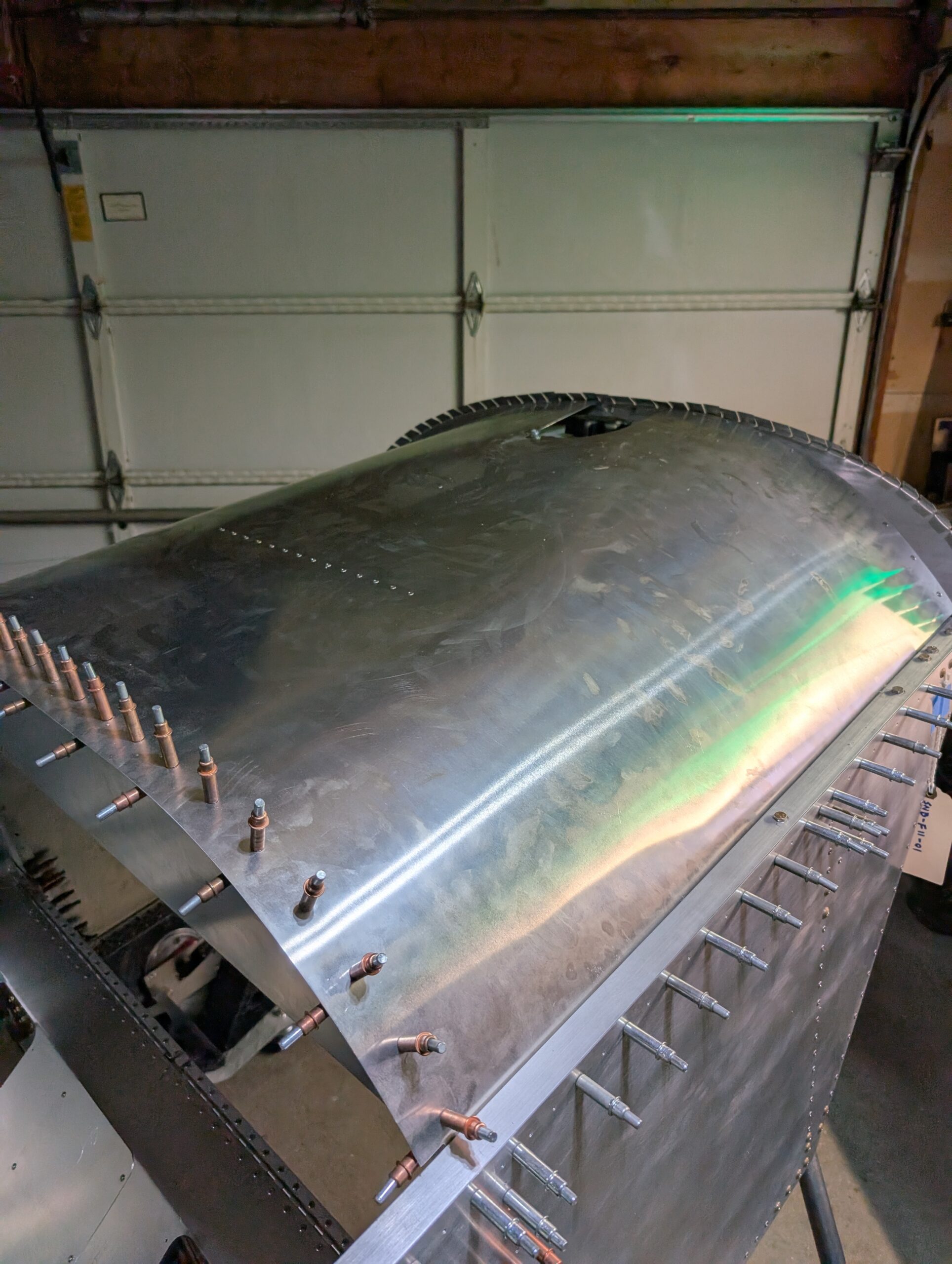

Fuel Tank Installation

Rinsed tank out with water to clear out debris from inside. Re-fit tank to fuselage and trimmed fuel bay area slightly more to accommodate vent fitting. Clecoed tank stop into place and confirmed tank was sitting full forward. Installed fuel…

-

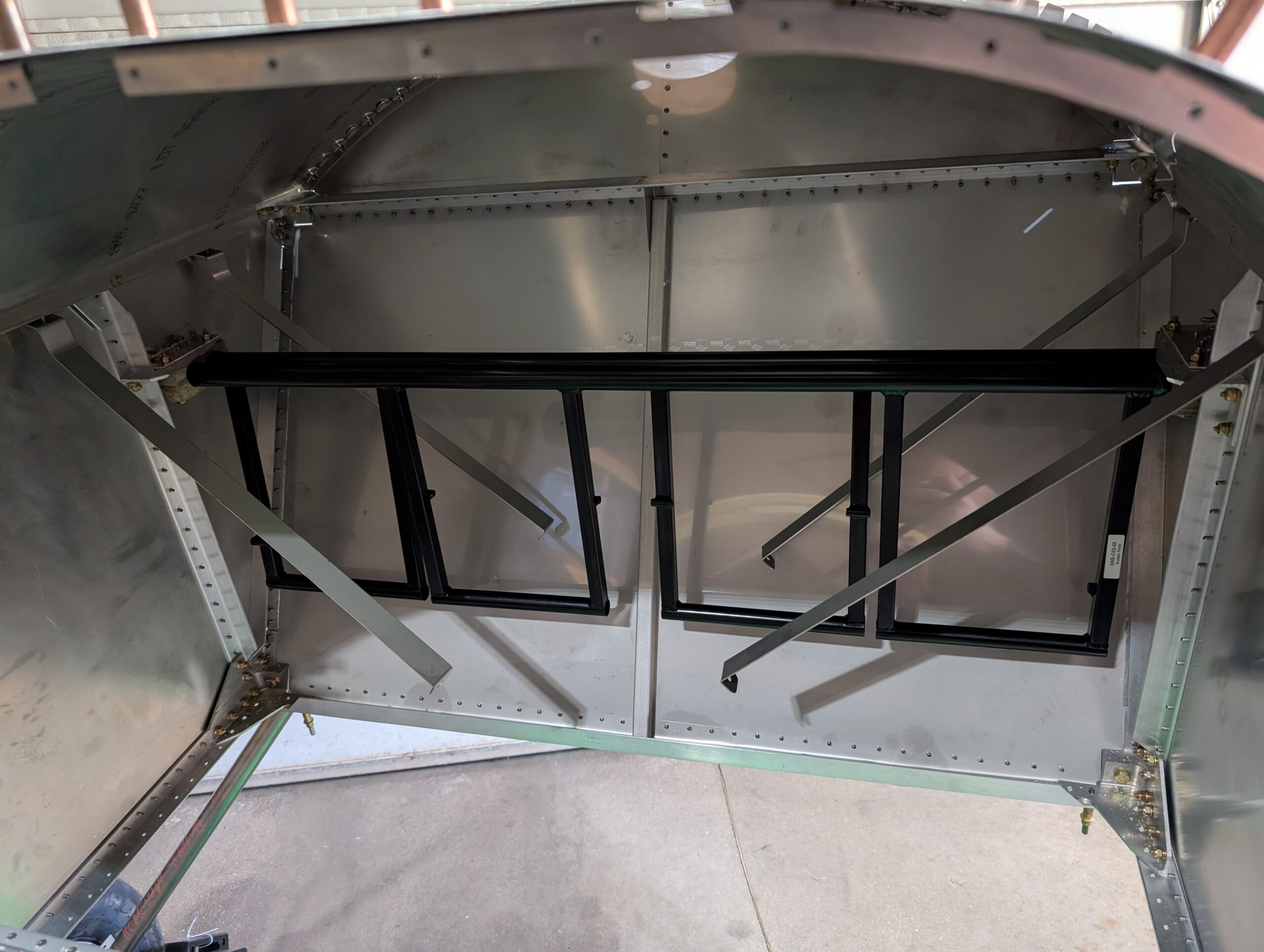

Panel Redesign – Part 1

After discovering issues with the panel cover, reached out to Sonex tech support and obtained original STL file. Printed out layout and compared to existing panel blank; much better fit. Converted STL into Solidworks file for panel redesign. Hours Worked:…

-

Rudder System Installation – Part 1

Located rudder pivot blocks onto fuselage and temporarily inserted rudder pedals to check fit. Fit and function seemed good so clamped blocks to fuselage and drilled forward mounting holes. Will need to remove assembly to apply grease in future. Hours…

-

Rudder System Prep – Part 1

Cut rudder pedal pivot blocks from Phenolic sheet. Matched similar blocks together and rough sanded. Clamped blocks together then drilled mount holes with drill press. Temporarily bolted blocks together and sanded edges flat. Marked holes for rudder pedals then through…

-

Follow-up Storage Treatment #2

Performed long-term storage procedure IAW Jabiru Maintenance Manual. Removed plugs and lubricated cylinders with Phillips 20W50 Anti-Rust Oil. Reinstalled plugs but did not torque. Removed rocker covers and lubricated rocker chambers with same oil. Reinstalled rocker covers but did not…

-

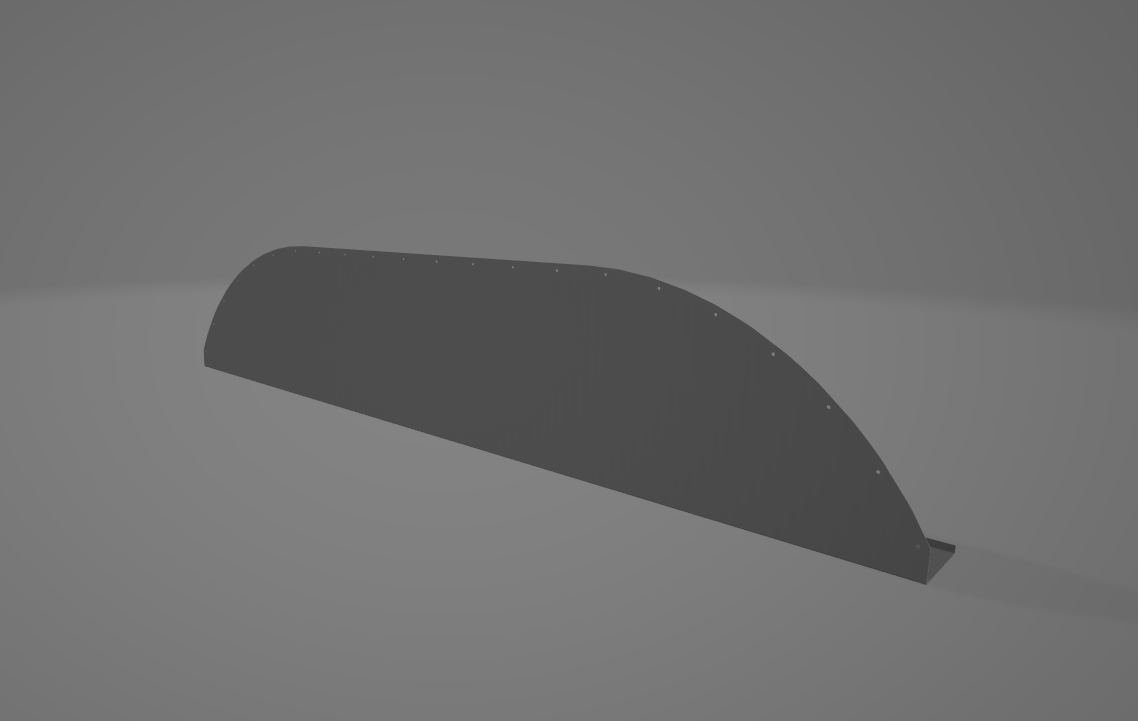

Fuel Tank Prep – Part 2

Drilled hole in fuel tank for fuel vent “oops” fitting then deburred/cleaned. Temporarily installed fuel tank straps and fuel tank then marked location of fuel tank vent on glareshield with strap duplicator. Removed fuel tank and drilled slightly oversized clearance…