-

Initial Engine Mounting

Began process of mounting engine to determine firewall location of other items by using engine hoist to lift engine off of table and onto airframe. Placed ACV-J01-10 engine shock mounts onto engine mount then maneuvered engine onto airframe. Used bolt…

-

Final Tail Installation – Part 4

Painted tail fairing angles with white spray paint then installed onto tail. T01 complete! Hours Worked: 0.72

-

Battery Box – Take 2

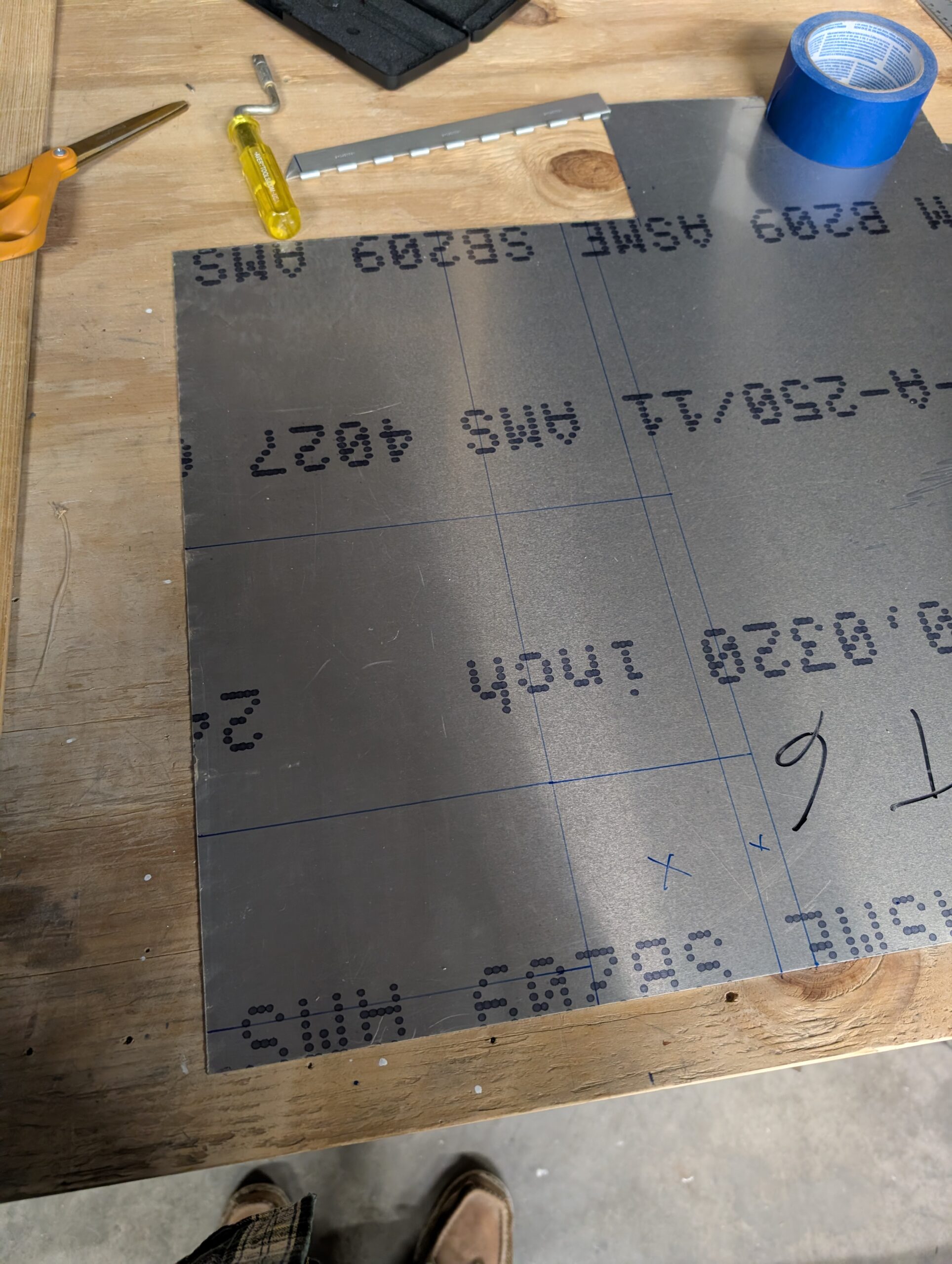

Second attempt at making battery box by recutting out template from 0.032 sheet stock and bending with bench bender. Deviated from plans design by omitting LH side panel to be replaced with hinged panel for side removal of battery. Cut…

-

Battery Box – Take 1

Measured out ETX900 battery to make flat sheet template for cutting battery box. Added 1/4″ to depth to account for edge of piano hinge on LH side. Drilled corner relief holes and mounting rivet holes then cut flat template with…

-

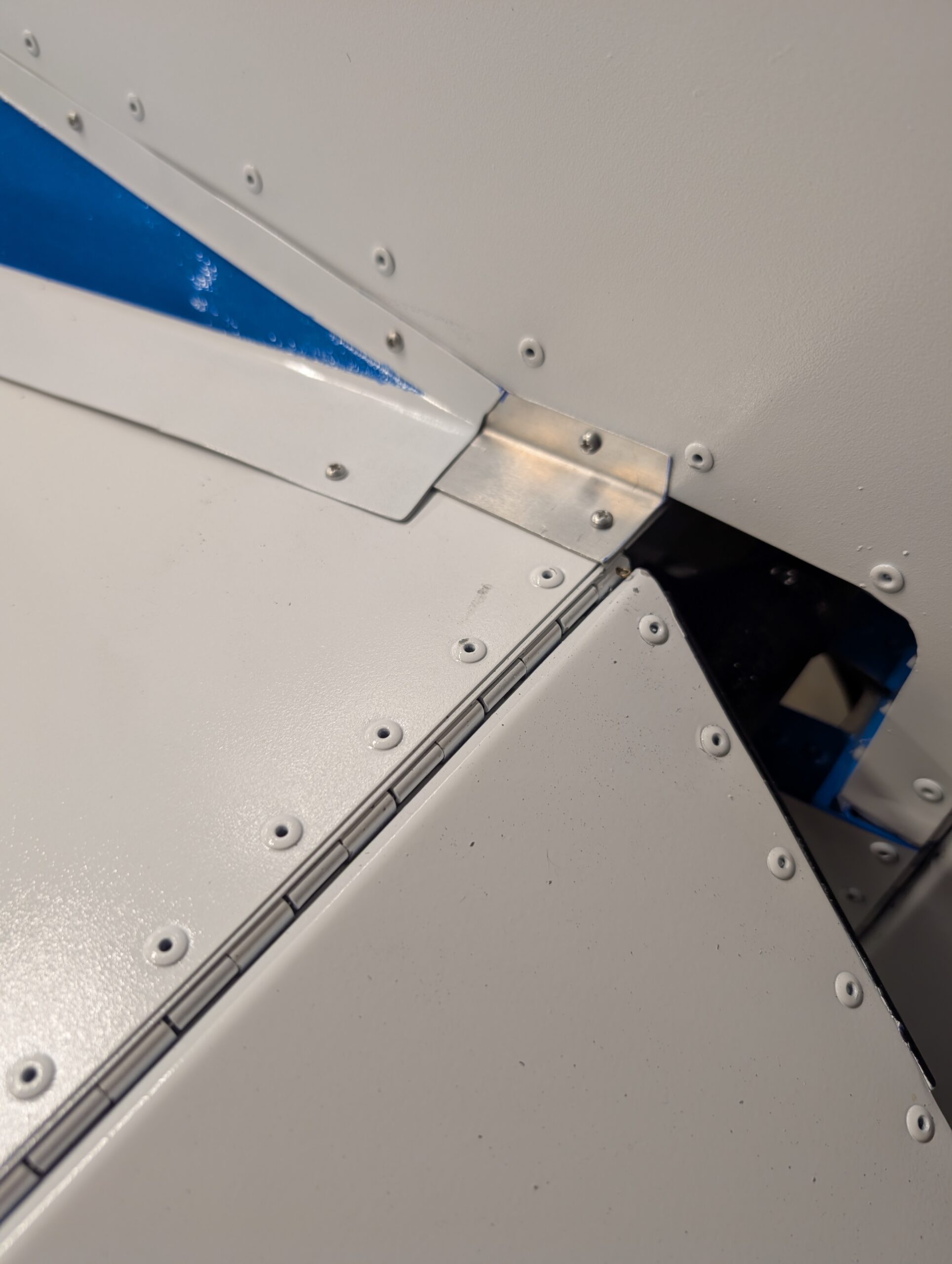

Tail Fairing Panels – Part 3

In lieu of using plan -06 angles to cover small gap behind tail fairing, opted to create a custom piece to seal up compartment where ELT sits. Cut Z01-03 stock to size and slipped underneath tail panel fairings. Overlapped furthest…

-

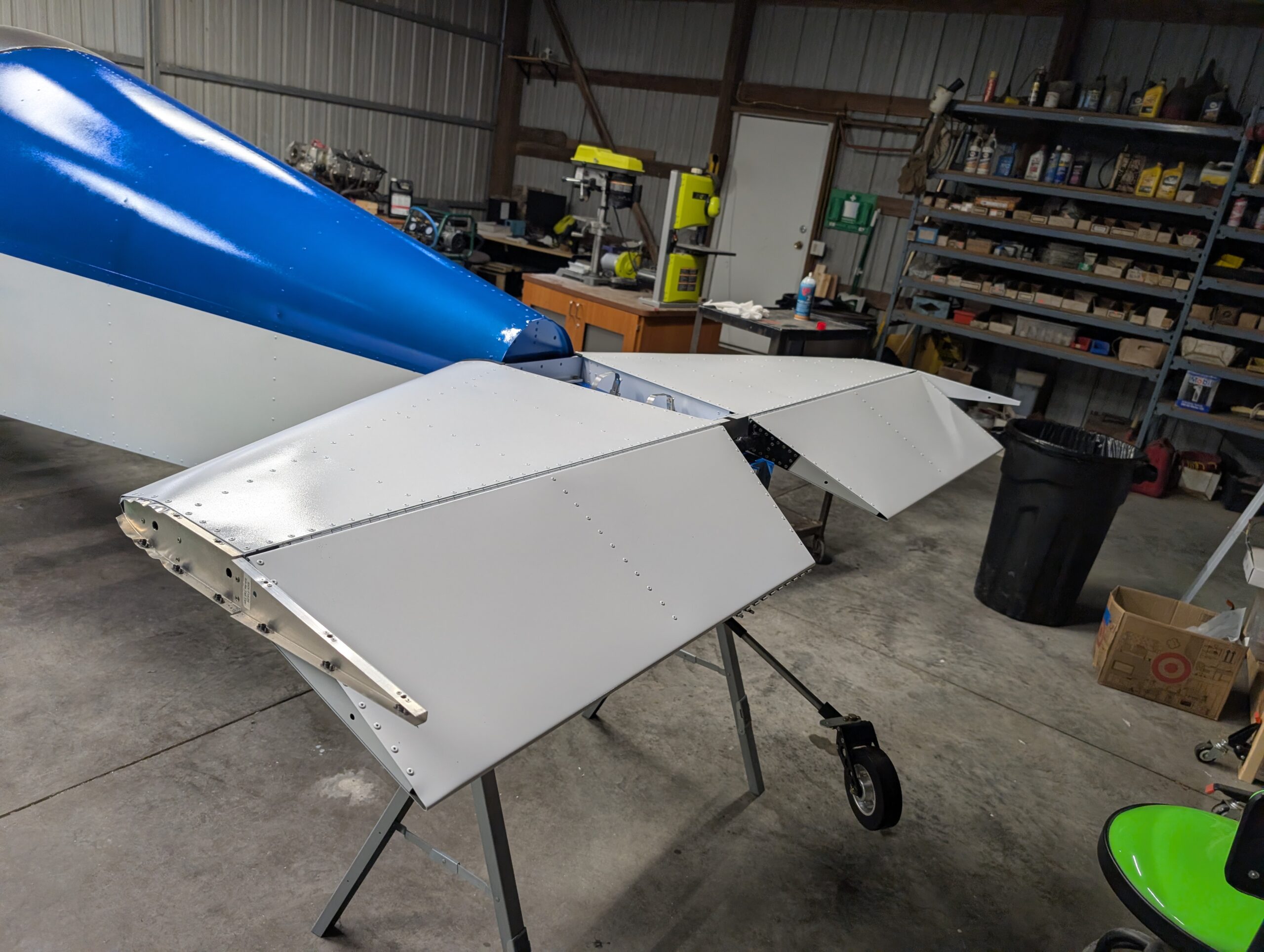

Tail Tips Installation

Installed remaining tail tips onto tail feathers with AN526-832 screws. T14 complete! Hours Worked: 0.44

-

Final Tail Installation – Part 3

Installed vertical stabilizer onto fuselage. Replaced AN3-6A bolts in tail with AN3-5A bolts for better fit and to ensure nut wasn’t bottoming out on bolts. Installed weather stripping on bottom edge of vertical stabilizer. Removed hinge pin from rudder installed…

-

Final Tail Installation – Part 2

Removed piano hinges installed in elevator during paint process and reamed out hinge loops. Installed elevator onto fuselage and horizontal stabilizer with piano hinges. Drilled cotter pin holes in hinge loops per plans and installed cotter pins. T02 complete! Hours…

-

Final Tail Installation – Part 1

Began final assembly of tail by mounting horizontal stabilizer to fuselage with AN4 hardware. Installed weatherstripping along inboard leading edge to help take up gap between stabilizer and turtledeck. Applied torque seal to mounting bolts. Hours Worked: 0.89

-

Canopy Installation – Part 3

Reattached canopy to fuselage with hinge pin and verified fitment along front and rear edges along with latch operation. Installed canopy retaining strap and tested operation. Located hole for canopy latch pin and drilled into upper longeron. Will remove plastic…

-

Fuselage and Wing Blue Paint

—

Final prepped wings, fuselage, ailerons, and tail fairing panels for blue paint by cleaning with pre paint prep. Setup items in paint booth then masked items while in booth. Painted in two batches just the blue color. Let paint cure…

-

Wingtip Installation

Installed nutplates for wingtip light fairings onto wing tips and riveted wingtips onto wings with AAP-42 aluminum rivets. After wingtips were installed, sanded rivets in preparation of paint. Hours Worked: 1.30