Fuselage

-

Glareshield Installation – Part 2

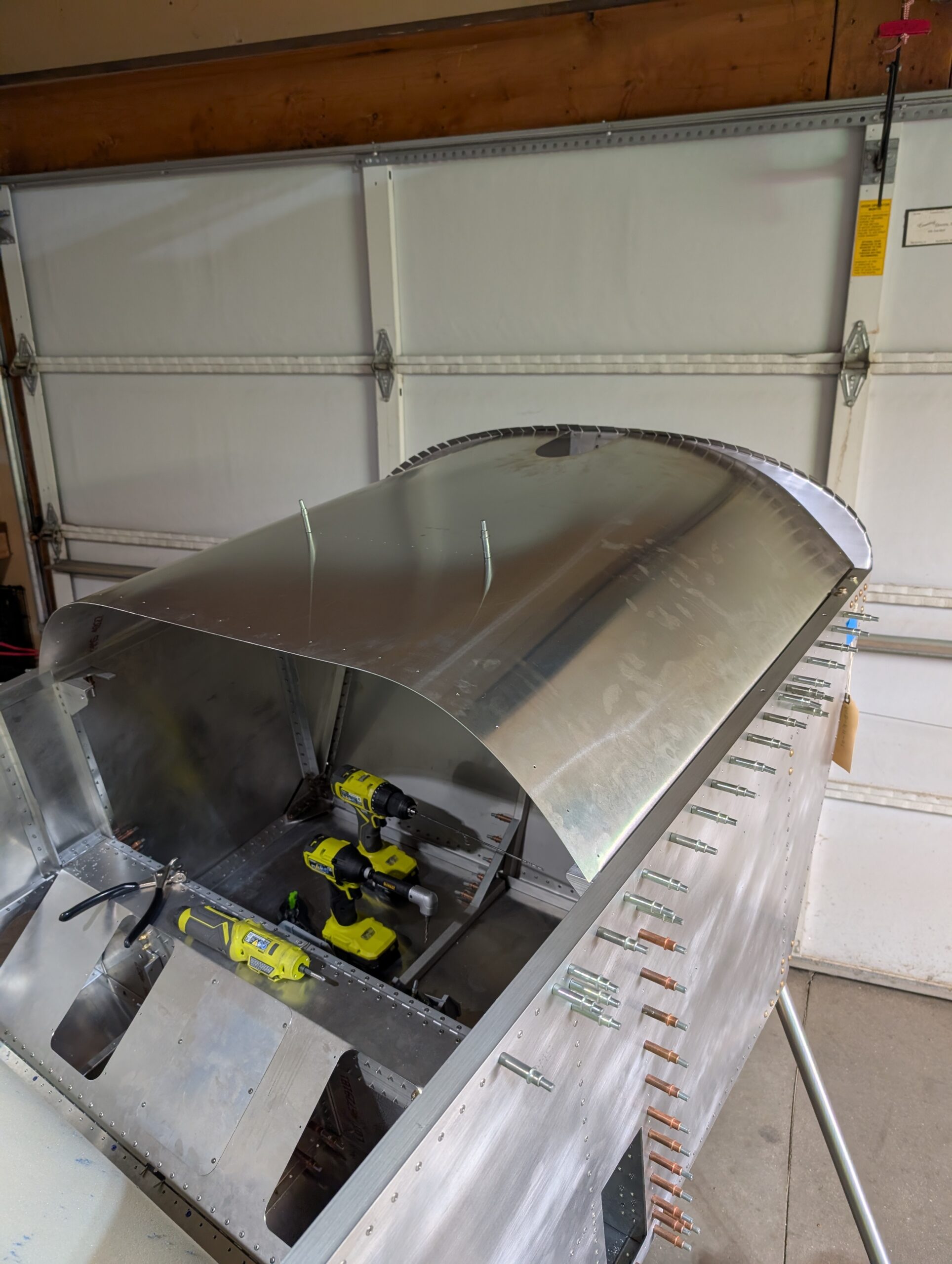

Made temporary seat cushions out of old mattress pad. Realigned glareshield to longerons and upper firewall and pilot drilled glareshield to firewall angle. Located instrument panel 3/4″ back from edge of glareshield and pilot drilled glareshield to instrument panel angle. Updrilled all glareshield holes. Hours Worked: 4.20

-

Glareshield Installation – Part 1

Located and clecoed firewall angles to upper firewall. Located and pilot drilled cross tie fittings to wing attach angle and upper longerons. Riveted cross tie fittings to wing attach angles but left clecoes in upper longerons so that forward spar tunnel can be removed. Located glare shield onto fuselage and pilot drilled to upper longerons.…

-

Instrument Panel Prep

Marked and bent -05 and -09 angles. Located -05 instrument Panel angles to back of instrument Panel and drilled/clecoed. Will install final rivets and dimple once panel is cut out. Hours Worked: 1.88

-

Seat Installation – Part 3

Riveted forward seat pan hinge half to spar tunnel. Marked and located upper seat back hinge half onto cross tie box and pilot drilled. Updrilled hinge, deburred, and riveted. Located rear seat pan centered to ribs and pilot drilled. Located seat support strap on seat attach angles and pilot drilled. Updrilled assembly then located and…

-

Seat Installation – Part 2

Updrilled hinge halves on seat pan channel, disassembled, deburred then riveted into final position. Installed forward seat pan with hinge pins then pinned forward mount hinge onto assembly. Located forward hinge onto spar tunnel and pilot drilled then updrilled. Removed forward hinge from aircraft then deburred spar tunnel and hinge holes. Hours Worked: 1.50

-

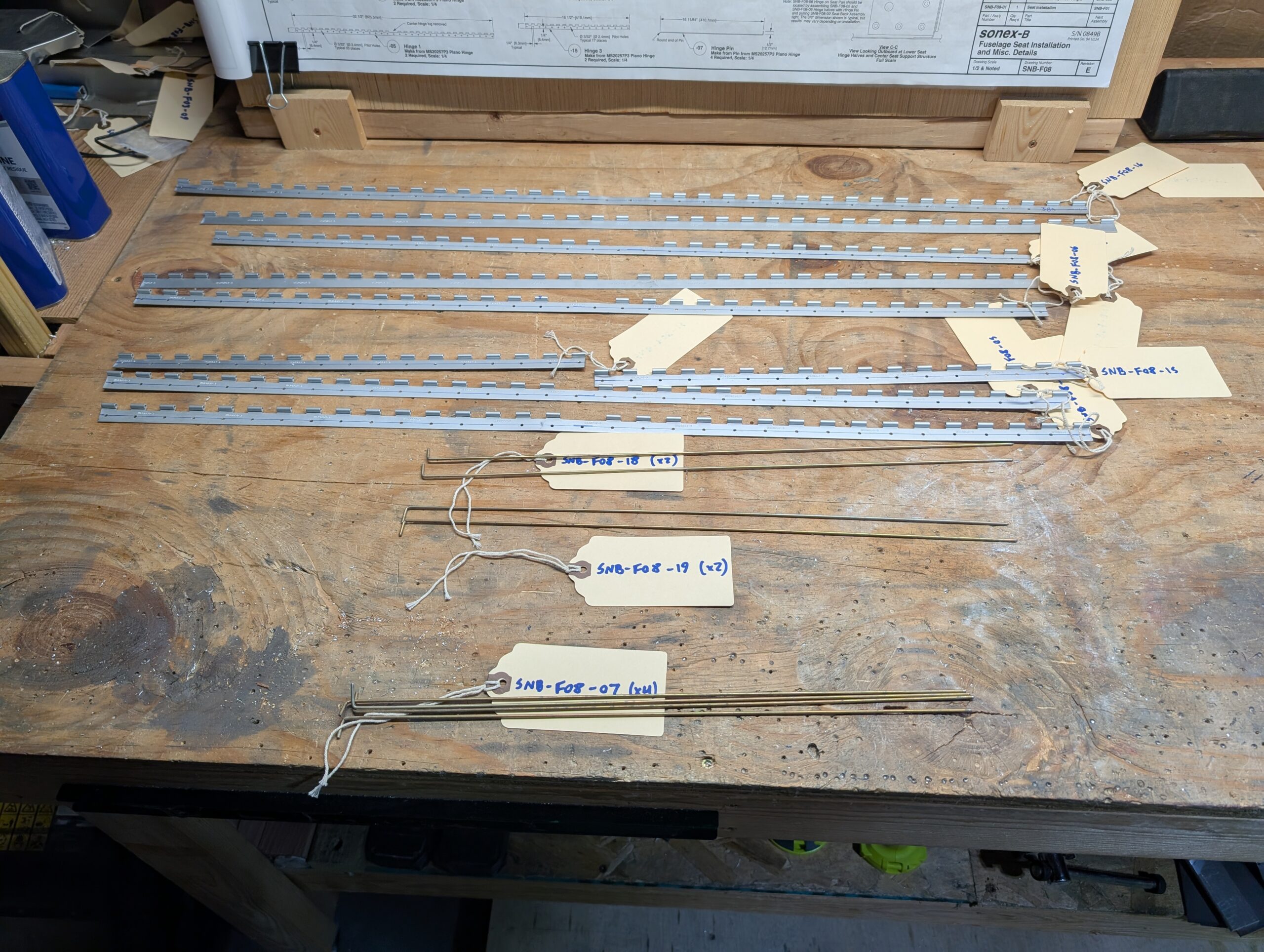

Seat Installation – Part 1

Created miscellaneous hinges and hinge pins from P3 piano hinge stock. Assembled and riveted -02 and -04 seat pan assemblies. Located and pilot drilled hinge half’s to forward seat pan channel. Hours Worked: 6.60

-

Aft Forward Fuselage Assembly – Part 4

Disassembled seat pans/channels to deburr and clean. Riveted seat pans and channels together then clecoed into fuselage. Riveted rear of assembly to aft seat belt channel and left clecoes in for center seatbelt channels and aft tunnel web spar per plans. Deburred new holes in forward fuselage floor then clecoed back onto fuselage. F09 complete!…

-

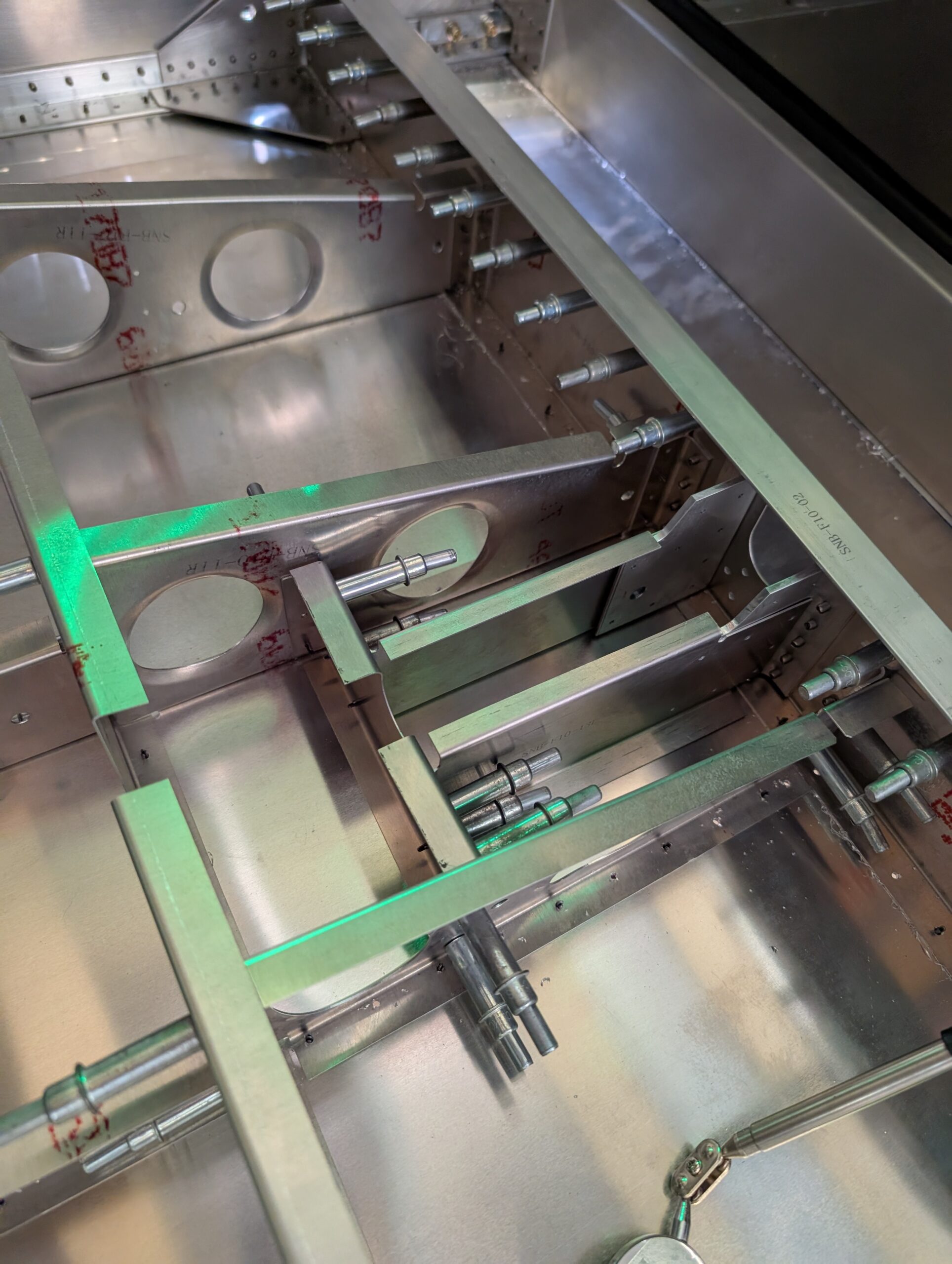

Aft Forward Fuselage Assembly – Part 3

Used rivet stems and clamps to hold center seatbelt channels into place while locating and pilot drilling seat ribs and channels to forward floor. Clecoed -14L/R angles into place. Located idler assembly and pilot drilled to lower cross member and seat belt attach assembly. Updrilled all holes in fuselage floor then removed floor for better…

-

Aft Forward Fuselage Assembly – Part 2

Pilot drilled and clecoed seat ribs and channels to fuselage floor. Clecoed together seat belt clips, attach channels, and seatbelt center channel and attached to inside seat pan ribs. Hours Worked: 0.82

-

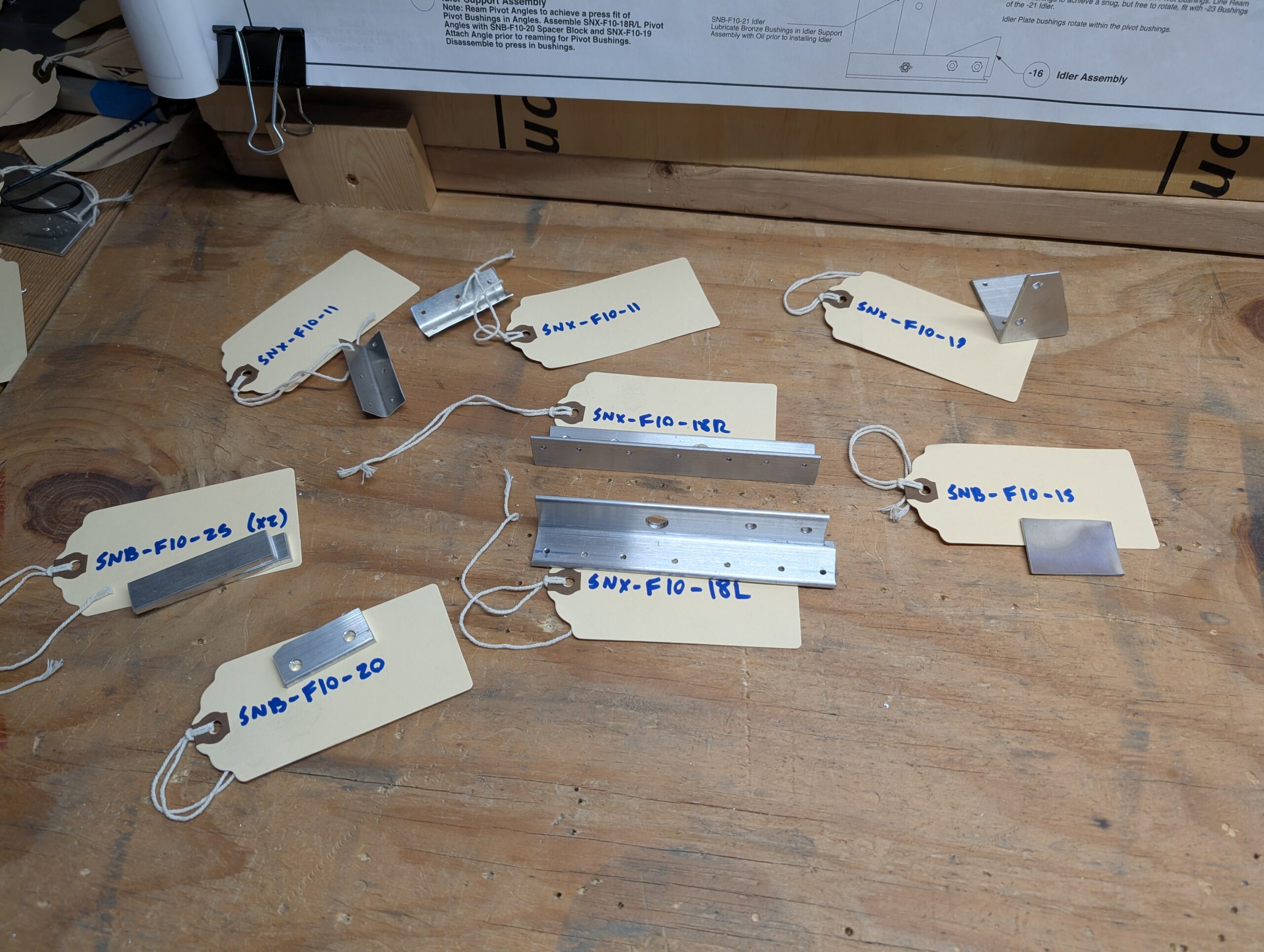

Forward Fuselage Part Prep – Part 2

Assembled F10-16 idler assembly (skipping -21 and -17 sub assemblies. Used vice to press in Symmco bushings to pivot angles. Lubricated bushings and pivot bearings with LPS-2 prior to assembly. Hours Worked: 0.57

-

Aft Forward Fuselage Assembly – Part 1

Following general construction order on plans, assembled -02 seat belt assembly and riveted. Fist assembly to fuselage and temporarily clecoed F10-02 angle to assembly to ensure straightness. Pilot drilled and clecoed assembly to side panels and floor. Determined SNB-F10-25 gusset spacers were the incorrect thickness so modified SNX spacers to work. Located spacers and gussets,…