-

Fresh Air Vents

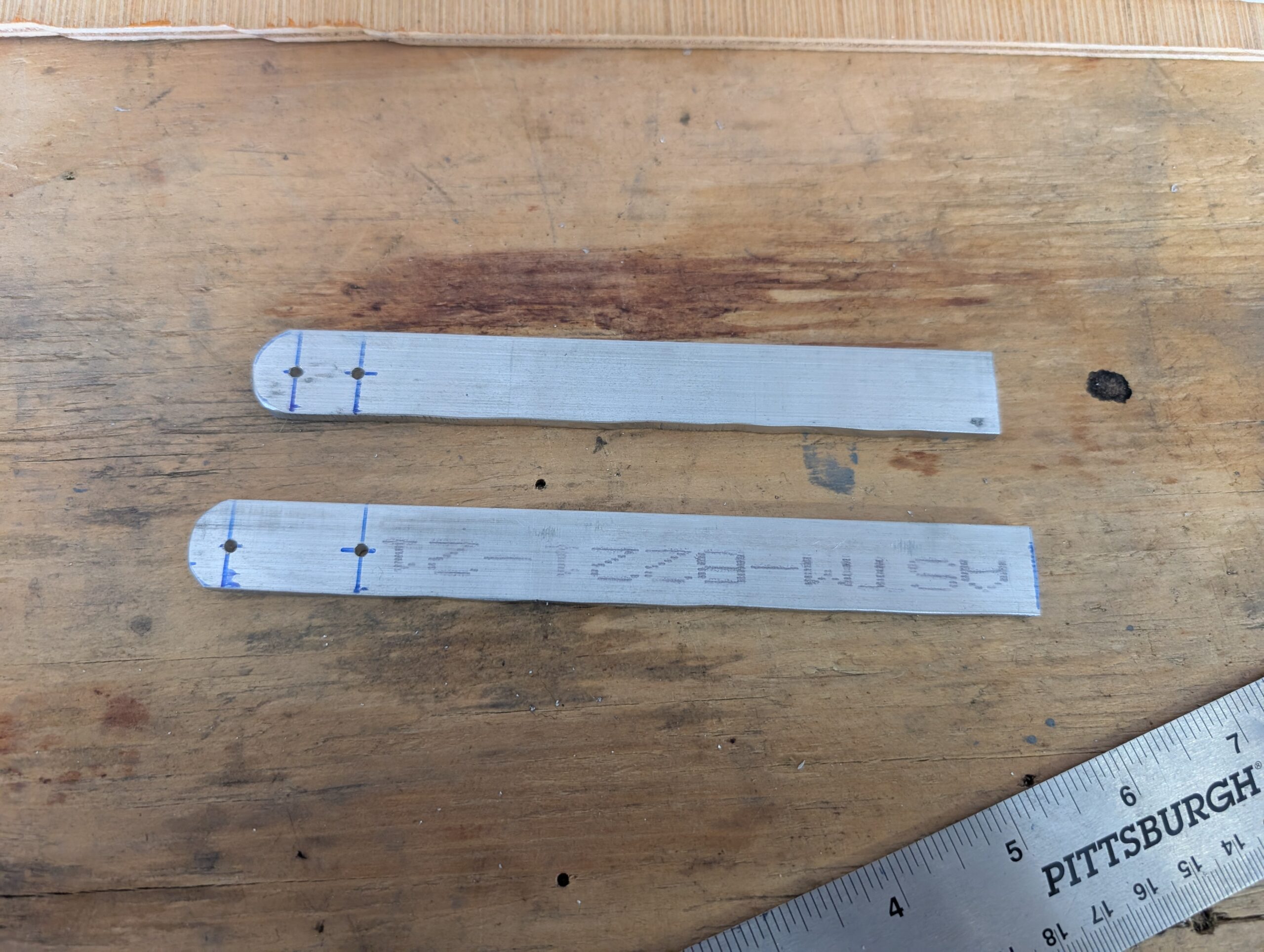

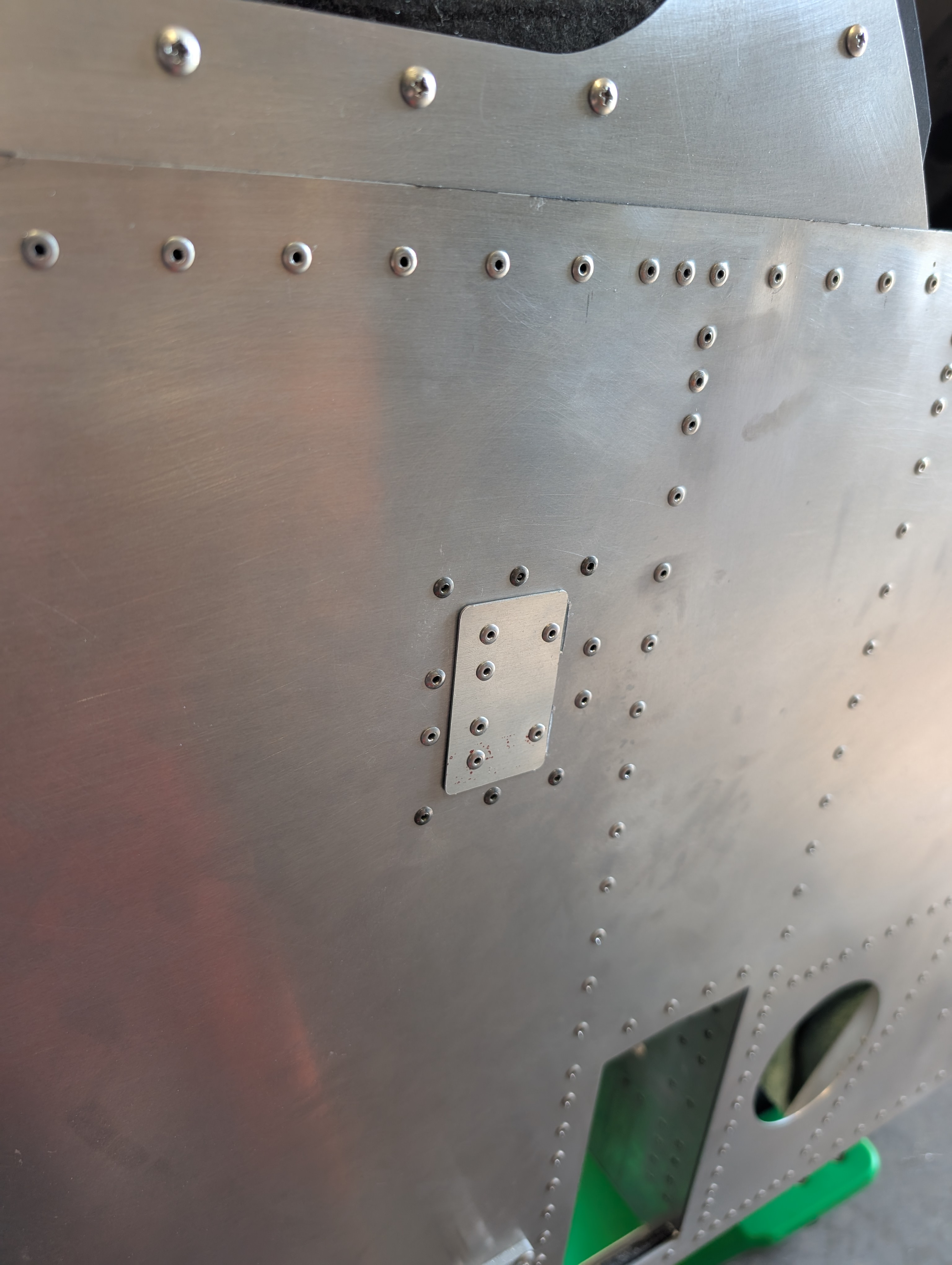

Rather than installing round vents in the windshield as is shown in the plans, decided to use the Vans vent sidewall kit. Worked on fresh air vents by cutting apart components from Vans vent kit and cleaning edges of parts.…

-

Windshield Installation – Part 6

Finished installing windshield onto fuselage by installing screws from front to back, skipping last bottom screw on each side. Aligned windshield bow with top center screw and installed sandwiching strap in between. Needed to run tap through each screw hole…

-

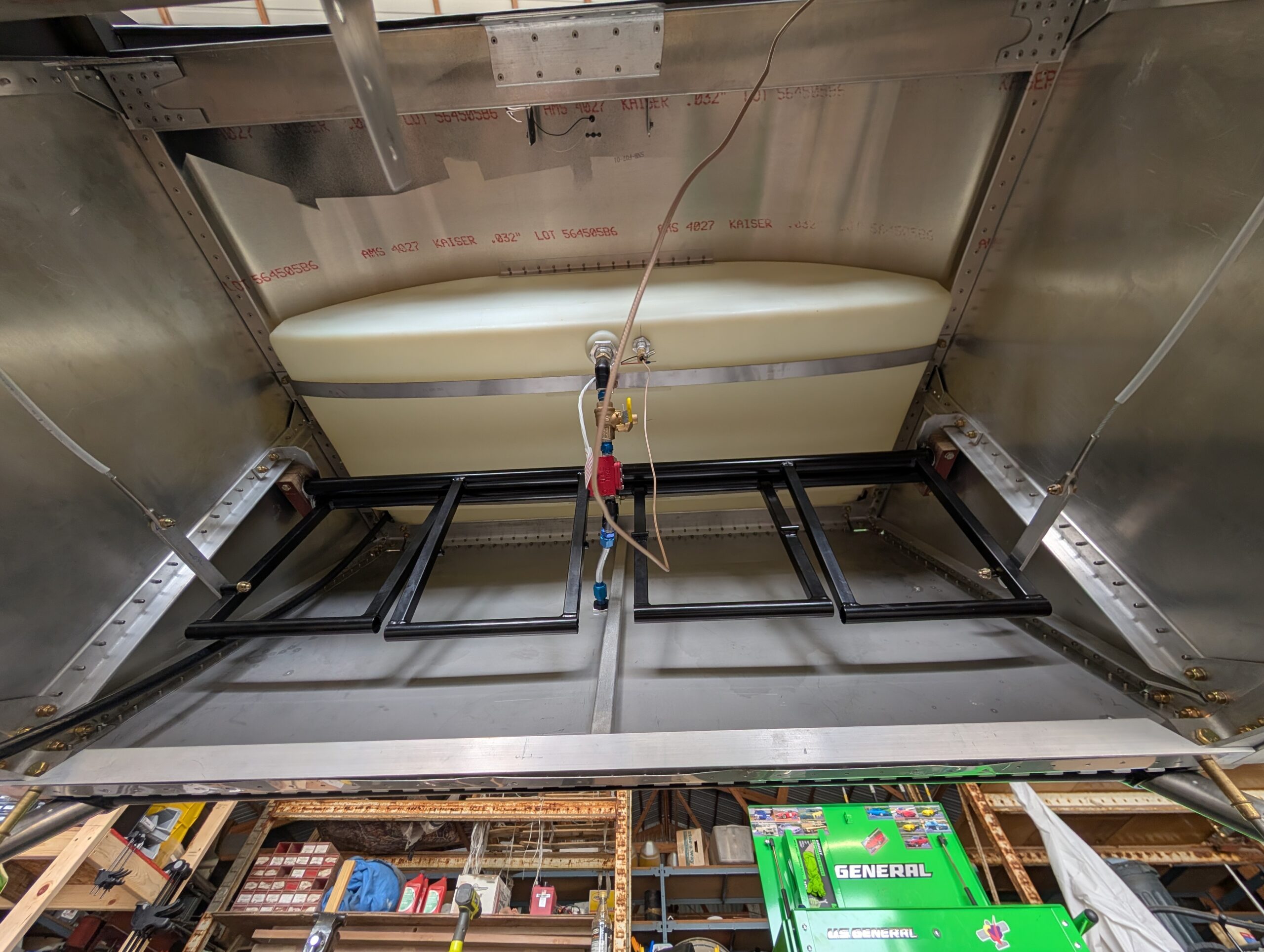

Windshield Installation – Part 5

Using two people, reinstalled bolts in upper longerons, windshield skirt, and upper motor mounts. Applied torque check to bolts to monitor torque. Slid windshield into place and began installing bolts starting from forward center and working backwards. Used a piece…

-

Rudder Control System – Part 2

Heated up C01-03 rudder spring stock with propane torch and bent springs to specs in plans. Previously tried to bend springs without heat and spring steel broke rather than bent. After installing springs into fuselage, discovered that plan dimensions were…

-

Rudder Control System – Part 1

Installed rudder pedals and mount blocks into fuselage. Applied white lithium grease to rudder pedals before tightening rudder pedal mount blocks. Fed rudder cables through aft fuselage and temporarily installed AN23 clevis pins into rudder horn. Installed cable fairleads into…

-

Windshield Installation – Part 4

Routed fuel vent hose up through hole in glareshield and attached to fuel vent fitting with hose clamp. Clecoed newly-painted windshield skirt onto fuselage. Hours Worked: 1.30

-

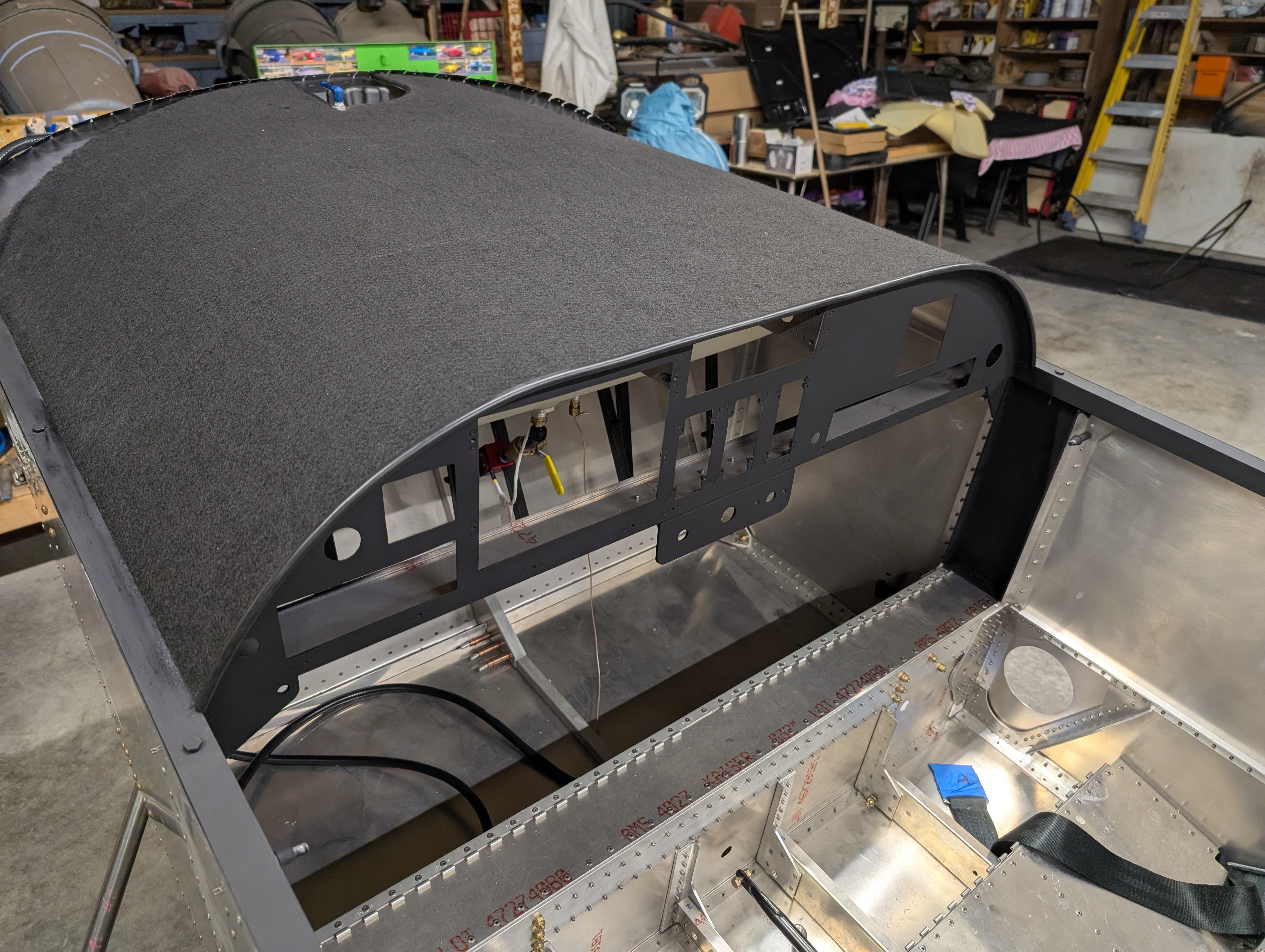

Glareshield Covering

Prepped glareshield for cover installation by scotchbriting surface then cleaning with paint prep. Blew debris off glareshield then laid fabric on top of glareshield and rough cut edges. Sprayed 3M Super 77 adhesive onto half of glareshield then rolled fabric…

-

Black Interior Paint

—

Setup paint booth and moved fuselage/canopy parts into spray booth. Cleaned all parts with pre paint prep and discovered that not all parts would fit at the same time. Sprayed two coats of primer on black fuselage parts and windshield…

-

Black Paint Prep

—

Prepped fuselage and windshield/canopy parts for black paint. Masked off glareshield and cabin area with painters tape then taped drop cloth over tape lines. Scotchbrited miscellaneous canopy and windshield parts in preparation for paint. Hours Worked: 1.94

-

Fuselage Side Panels – Part 1

Tested fuselage side panels by trimming RH side panel from ABS sheet and making small adjustments to test fit. Hours Worked: 1.50

-

Compass Mount Prep

Removed GPS175 tray from panel for better access. Marked out alignment guides on glareshield for compass. Pilot drilled holes using compass as template then updrilled for #6 screws. Used nut plate drill guide to drill nutplate mounting holes. Deburred holes…