-

Windshield Prep – Part 1

Began prepping the windshield components for paint and final assembly by updrilling and deburring the windshield skirt. Enlarged fuel door hole and installed Southco receptacle for fuel door fastener with flush rivets. Then updrilled windshield bow skirt and scotchbrited. Updrilled…

-

Panel and Glareshield Wrap up

Installed rivets between panel blank and cross tie fittings. Riveted lower control angle for throttle, mixture, and trim onto lower edge of panel blank. Installed temporary #6 screws into panel blank then flush riveted panel to angles. Then riveted panel…

-

Windshield Removal

Removed windshield components to prep for painting and updrilling. Deburred upper firewall holes. Hours Worked: 0.52

-

Fuselage Final Riveting – Part 4

Now that all work under the aft seat pan has been completed, clecoed aft seat pan to ribs and final riveted. Hours Worked: 1.09

-

Seatbelt Installation – Part 1

Began seatbelt installation by placing AN5 bolts in center seatbelt channel with grabber extension. Wrapped chrome ends of lap belts in painters tape to prevent scratching. Followed plans and placed buckle ends of seatbelt on inside. Set approximate lap belt…

-

Trim System Installation – Part 2

Finished trim system by installing last clamp on elevator pushrod and balance spring. Will wait to adjust until flight testing occurs. Also added torque seal to elevator push rod bolts. Hours Worked: 0.32

-

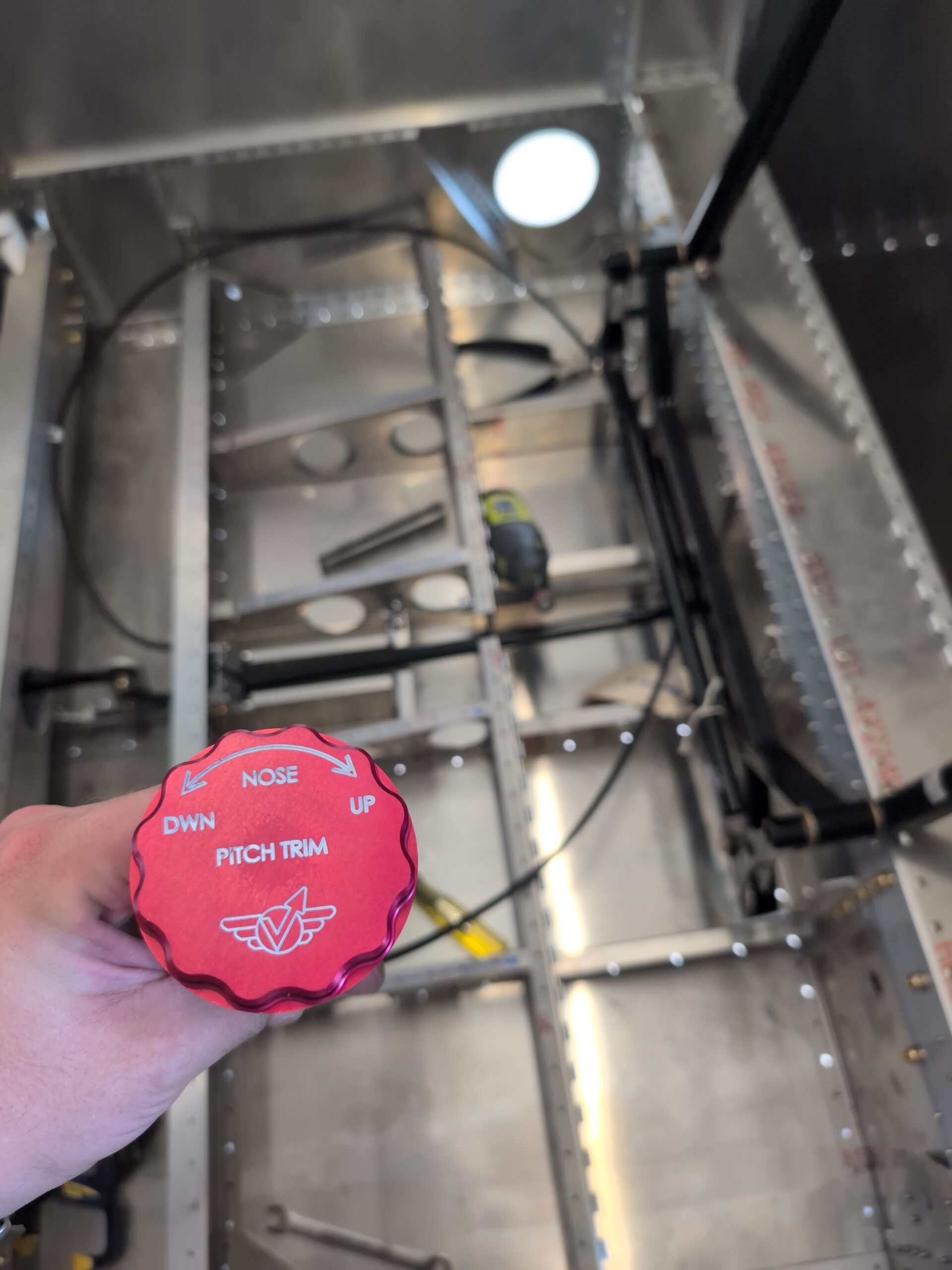

Trim System Installation – Part 1

Began trim system installation by removing lower instrument panel and drilling holes for throttle, mixture, and trim wheel. Measured and drilled hole for trim cable sleeve below seat pan. Mocked up cable run and trimmed around 18″ from cable and…

-

Elevator Control System – Part 1

Temporarily installed control stick assembly. Pressed SF-812-3 bushings into stick to idler bar and control frame then installed idler hardware permanently and stick hardware temporarily. Verified freedom of movement and clearances with idler bar. Pressed bushing into elevator push rod…

-

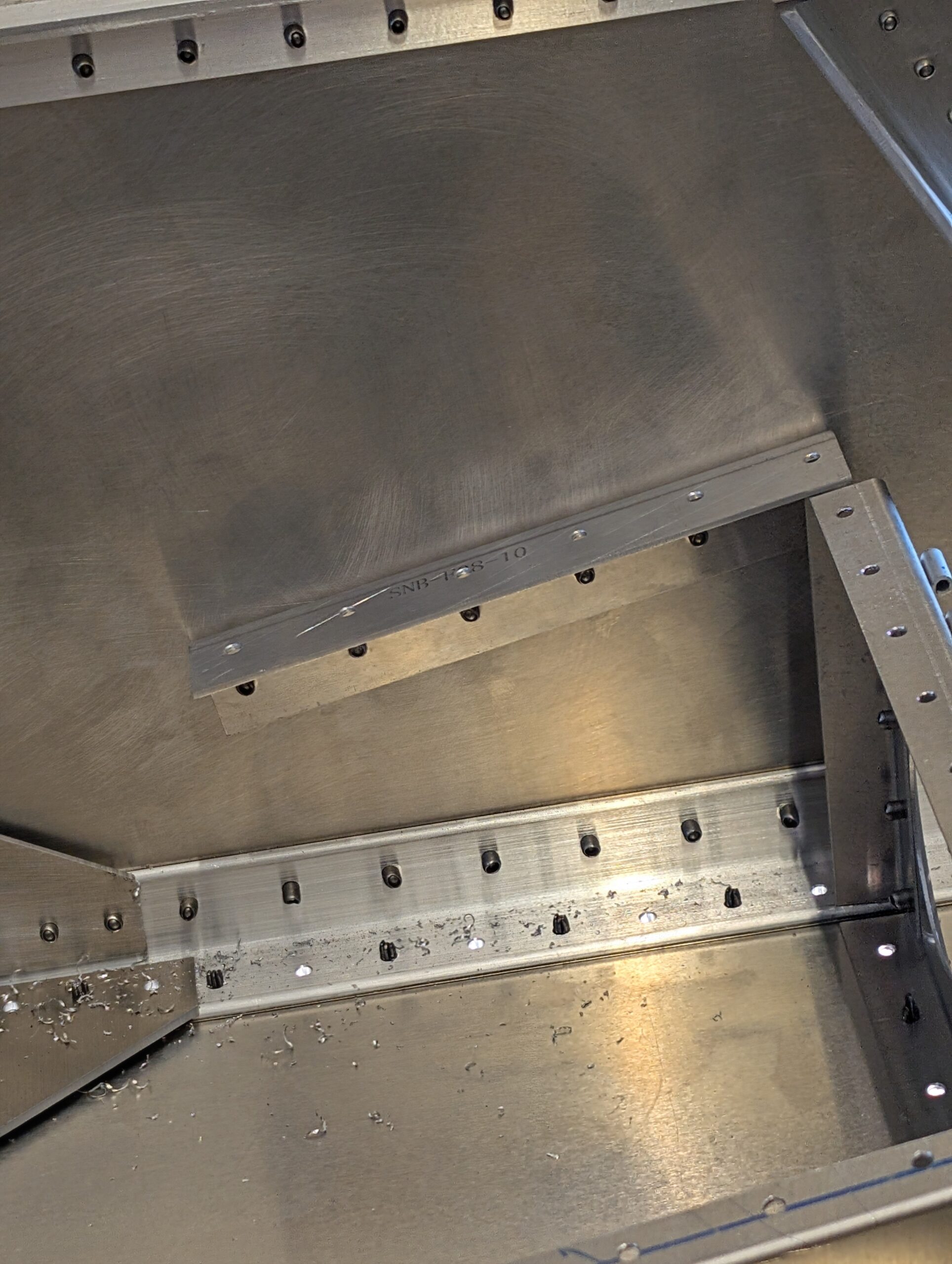

Fuselage Final Riveting – Part 3

Did some more final fuselage work by temporarily reinstalling forward fuselage floor then riveting rear spar angles to fuselage sides and forward seatbelt channel to inside seat ribs. Transferred pilot holes from angles on top of spar tunnel to fuselage…

-

Canopy Components – Part 3

Clamped canopy frame components together and checked fitment on fuselage. Forward windshield flange might need a bit of trimming but overall fit good. Pilot drilled then updrilled forward and aft canopy bows to side rails. Cut canopy hinge pieces from…

-

Windshield Installation – Part 3

Completed pilot drilling of windshield skirt holes into upper longerons. Updrilled skirt mounting holes in longerons and upper firewall. Decided not to updrill windshield holes since clecoes would not hold well in 9/64″ holes. Hours Worked: 1.25

-

Windshield Installation – Part 2

Clamped together rear edges of windshield skirt and windshield and pilot drilled pieces together starting at the top center and working down both sides. Marked centerline on the windshield bow and pilot drilled top center hole off of plane. Clecoed…