Powerplant

-

Engine Hardware Replacement

Replaced temporary engine mount hardware (too long) with properly sized AN4-46A bolts and AN363 nuts.

-

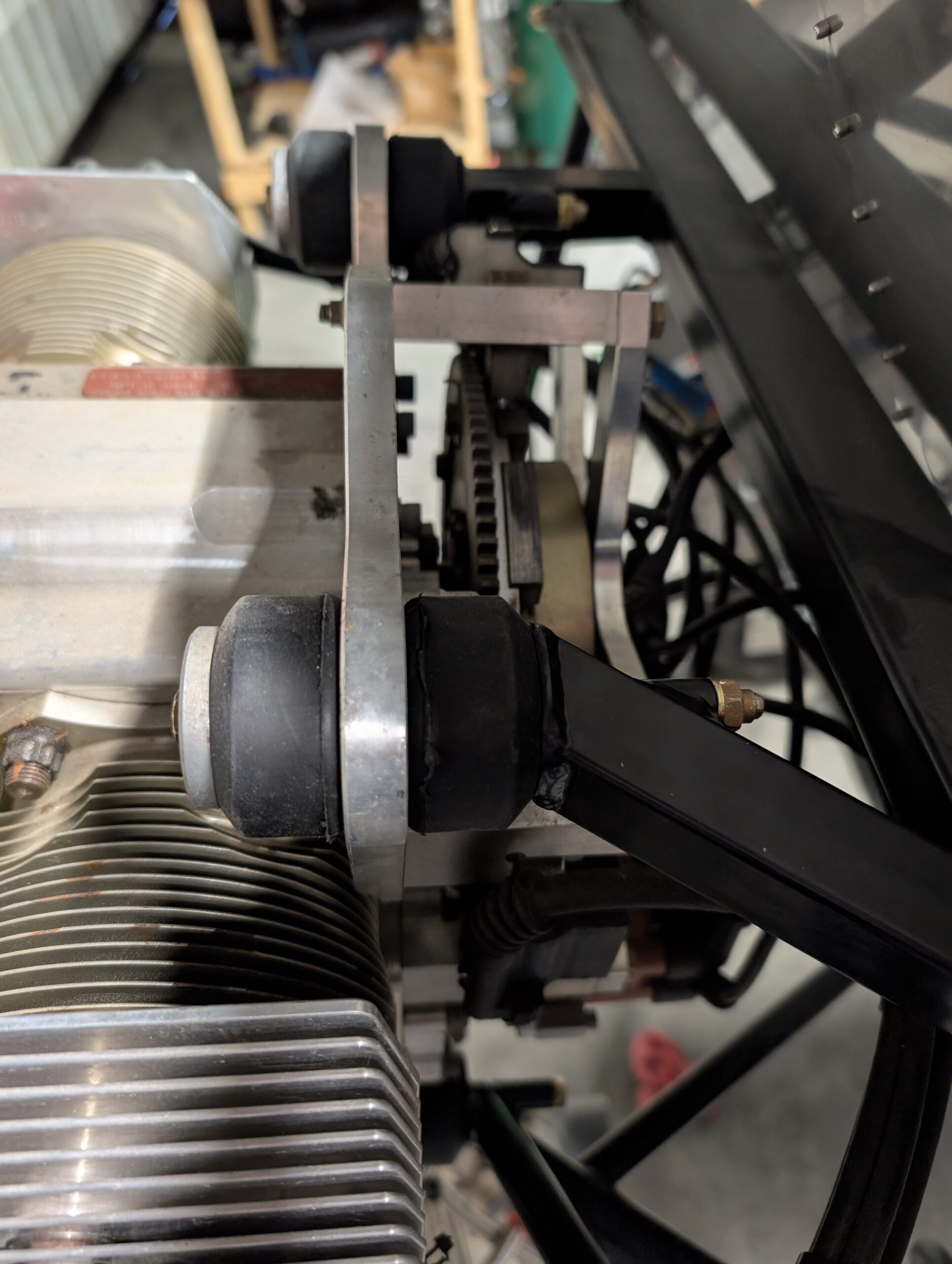

Initial Engine Mounting

Began process of mounting engine to determine firewall location of other items by using engine hoist to lift engine off of table and onto airframe. Placed ACV-J01-10 engine shock mounts onto engine mount then maneuvered engine onto airframe. Used bolt guides that came with engine to secure engine to airframe. Measurements for the AN4-51 bolts…

-

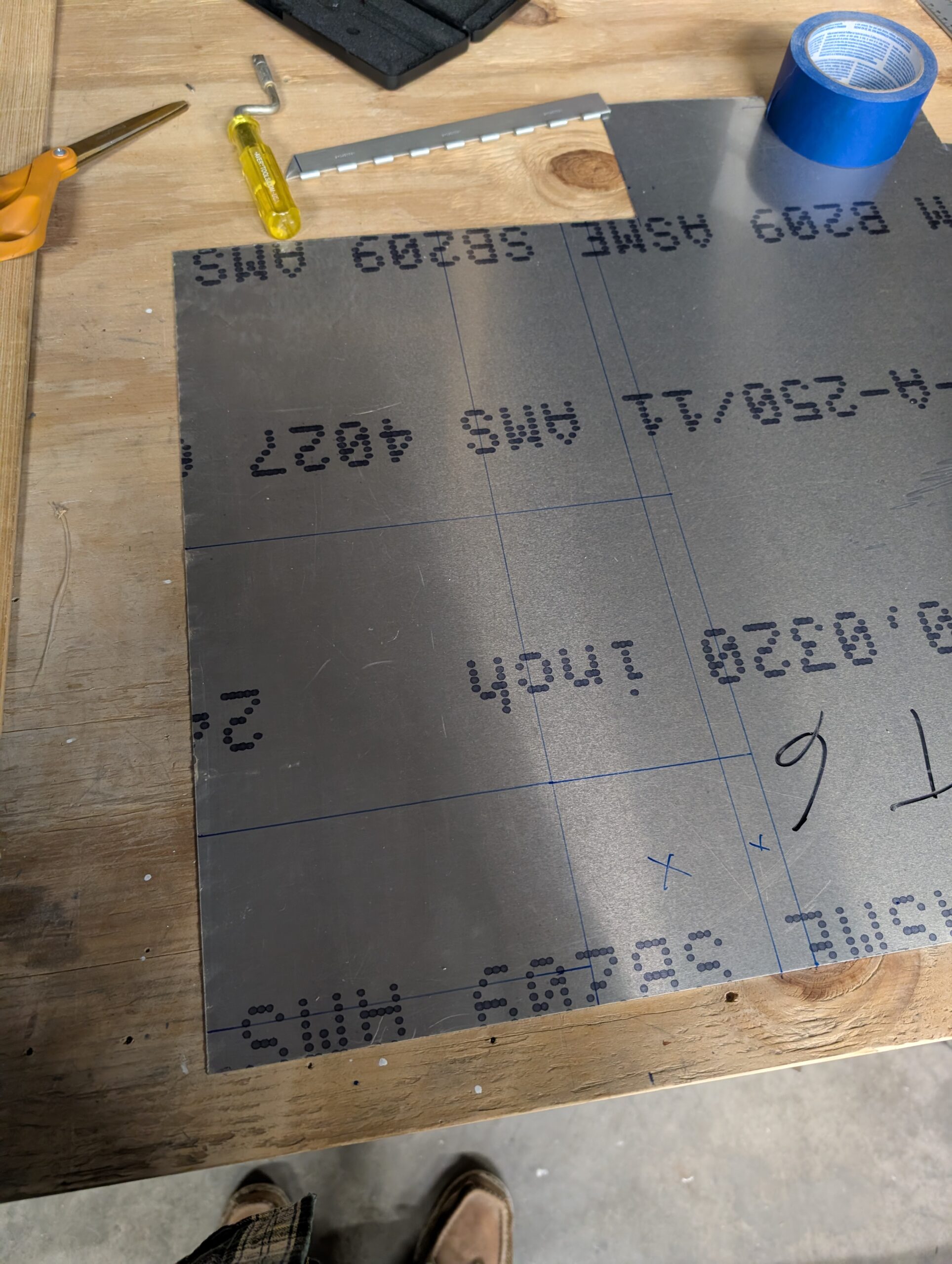

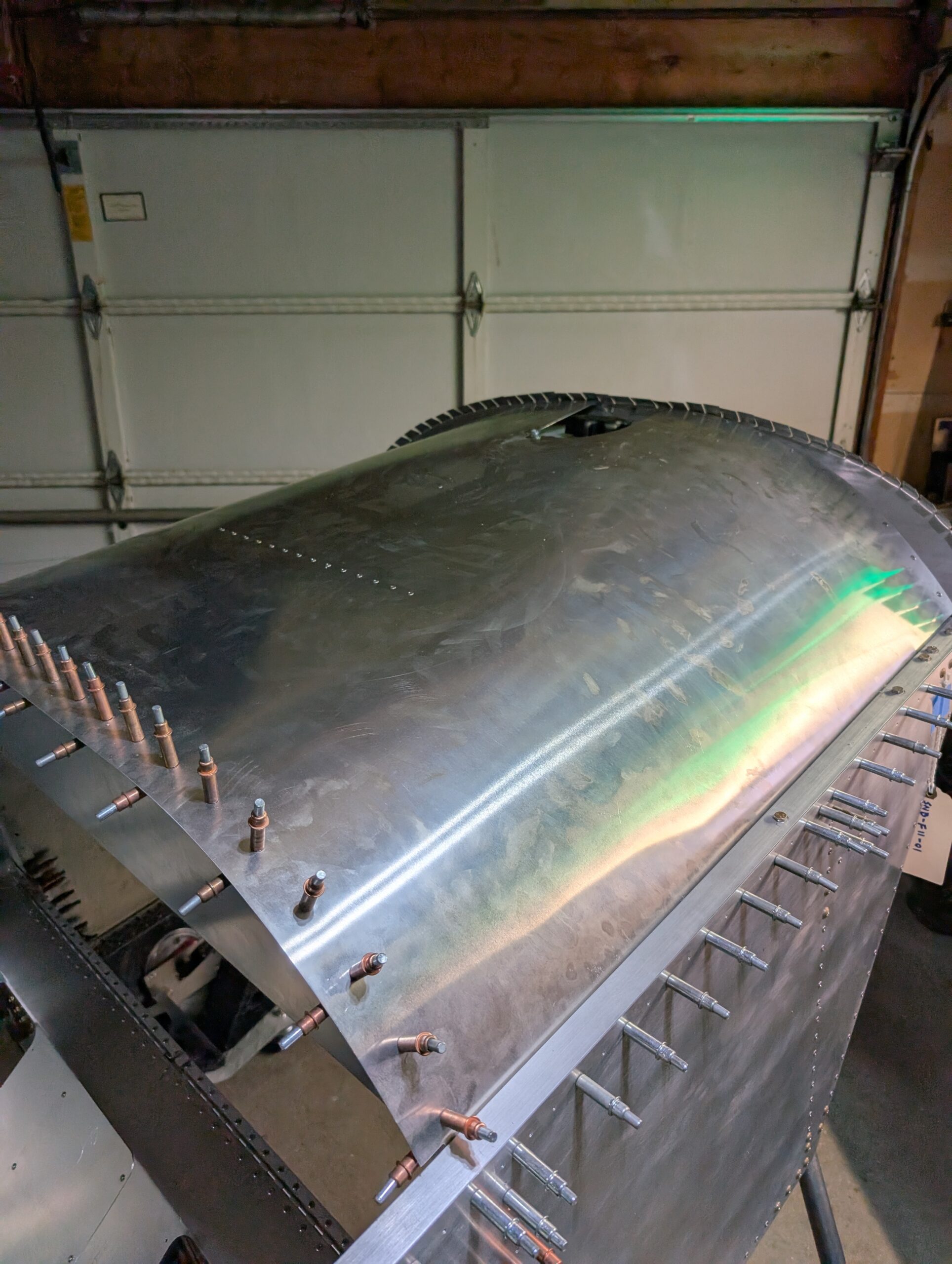

Battery Box – Take 2

Second attempt at making battery box by recutting out template from 0.032 sheet stock and bending with bench bender. Deviated from plans design by omitting LH side panel to be replaced with hinged panel for side removal of battery. Cut various lengths of -3 piano hinge and riveted hinge halves to battery box using flush…

-

Battery Box – Take 1

Measured out ETX900 battery to make flat sheet template for cutting battery box. Added 1/4″ to depth to account for edge of piano hinge on LH side. Drilled corner relief holes and mounting rivet holes then cut flat template with Andy snips. Bent flat sheet with bench brake then realized bends were going wrong direction…

-

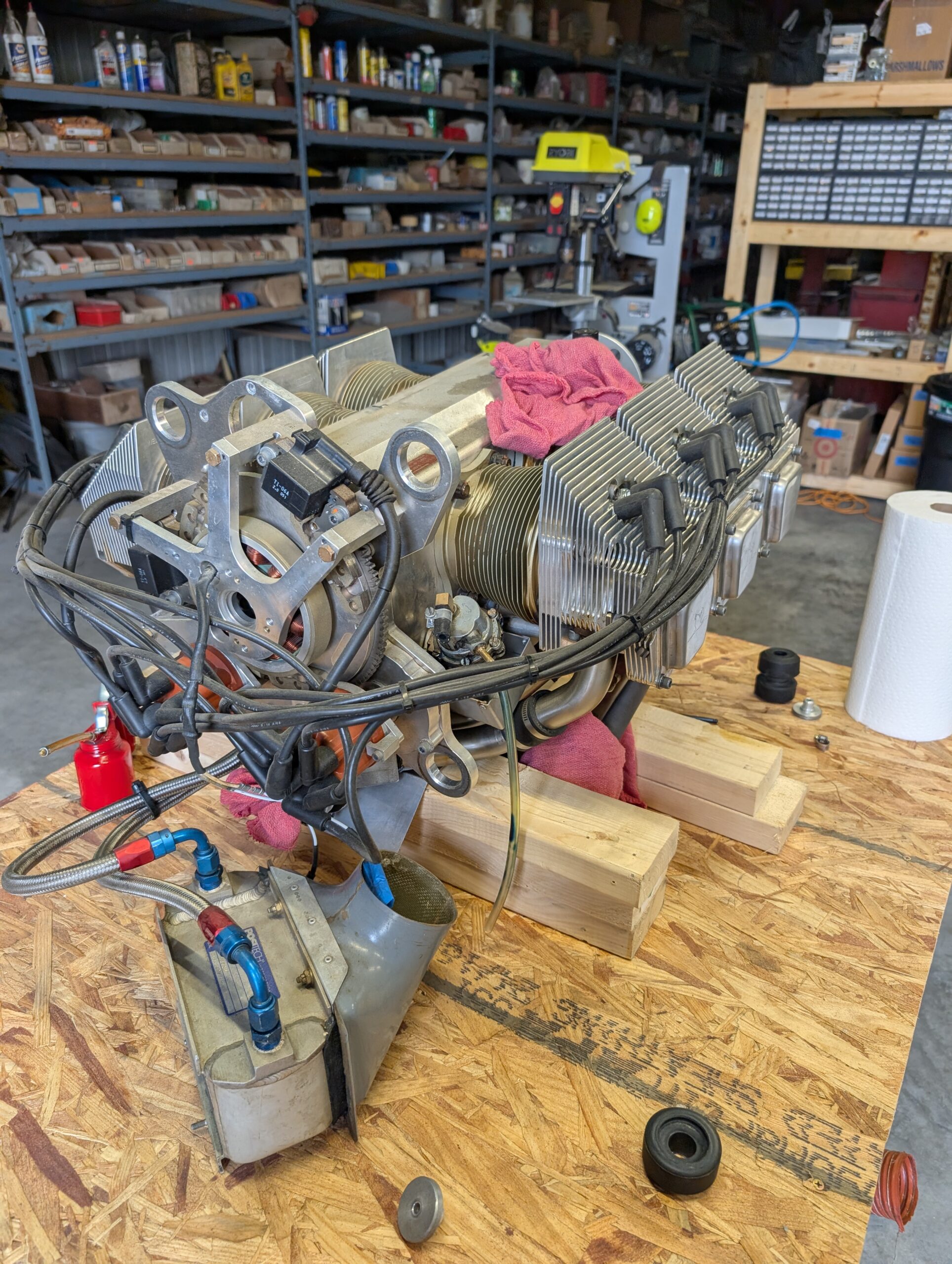

Follow-up Storage Treatment #4

Performed long-term storage procedure IAW Jabiru Maintenance Manual. Removed plugs and lubricated cylinders with Phillips 20W50 Anti-Rust Oil. Reinstalled plugs but did not torque. Removed rocker covers and lubricated rocker chambers with same oil. Reinstalled rocker covers but did not torque. Pulled prop through 15 times. Hours Worked: 0.58

-

Follow-up Storage Treatment #3

Performed long-term storage procedure IAW Jabiru Maintenance Manual. Removed plugs and lubricated cylinders with Phillips 20W50 Anti-Rust Oil. Reinstalled plugs but did not torque. Removed rocker covers and lubricated rocker chambers with same oil. Reinstalled rocker covers but did not torque. Pulled prop through 15 times. Hours Worked: 0.63

-

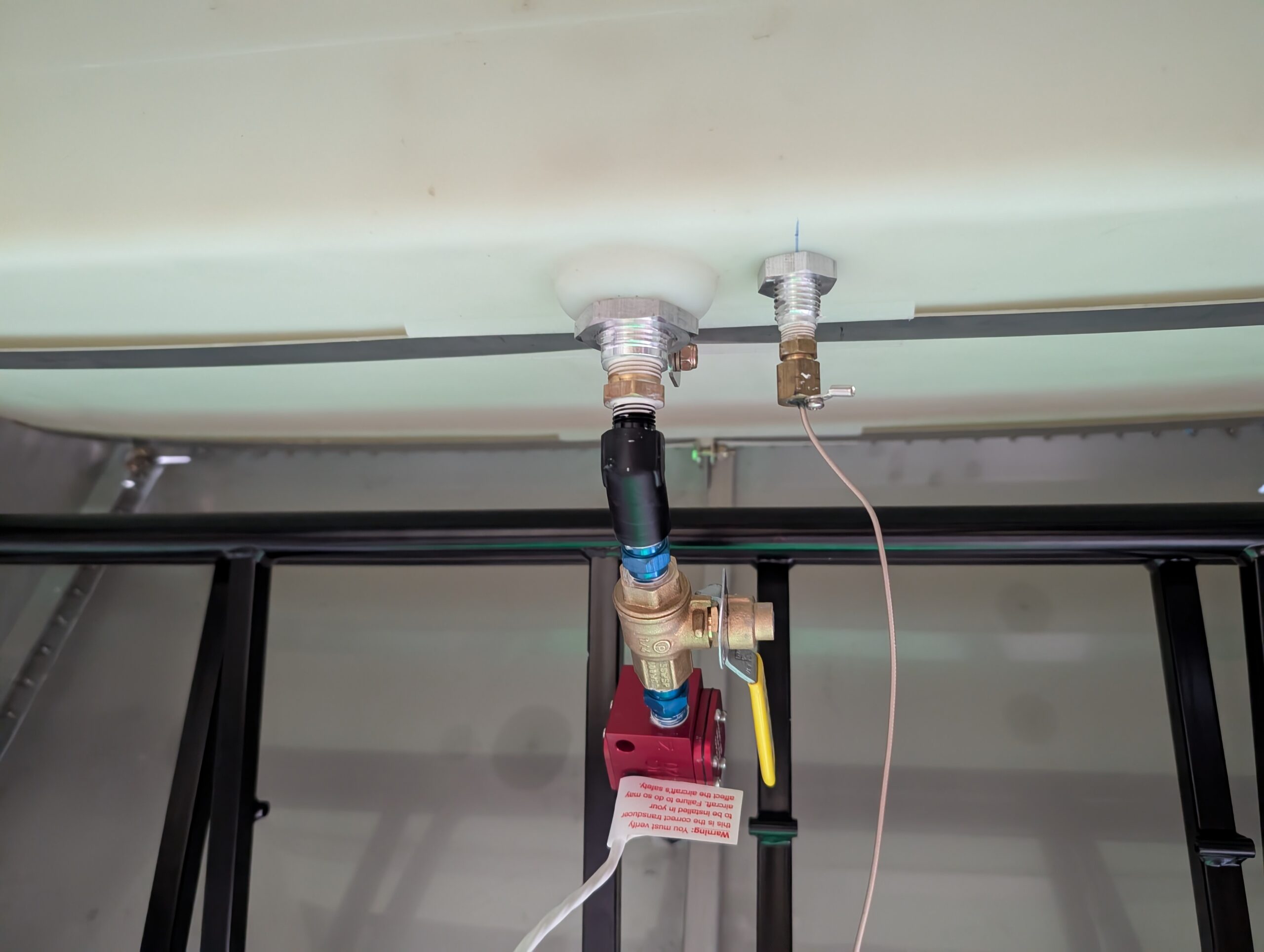

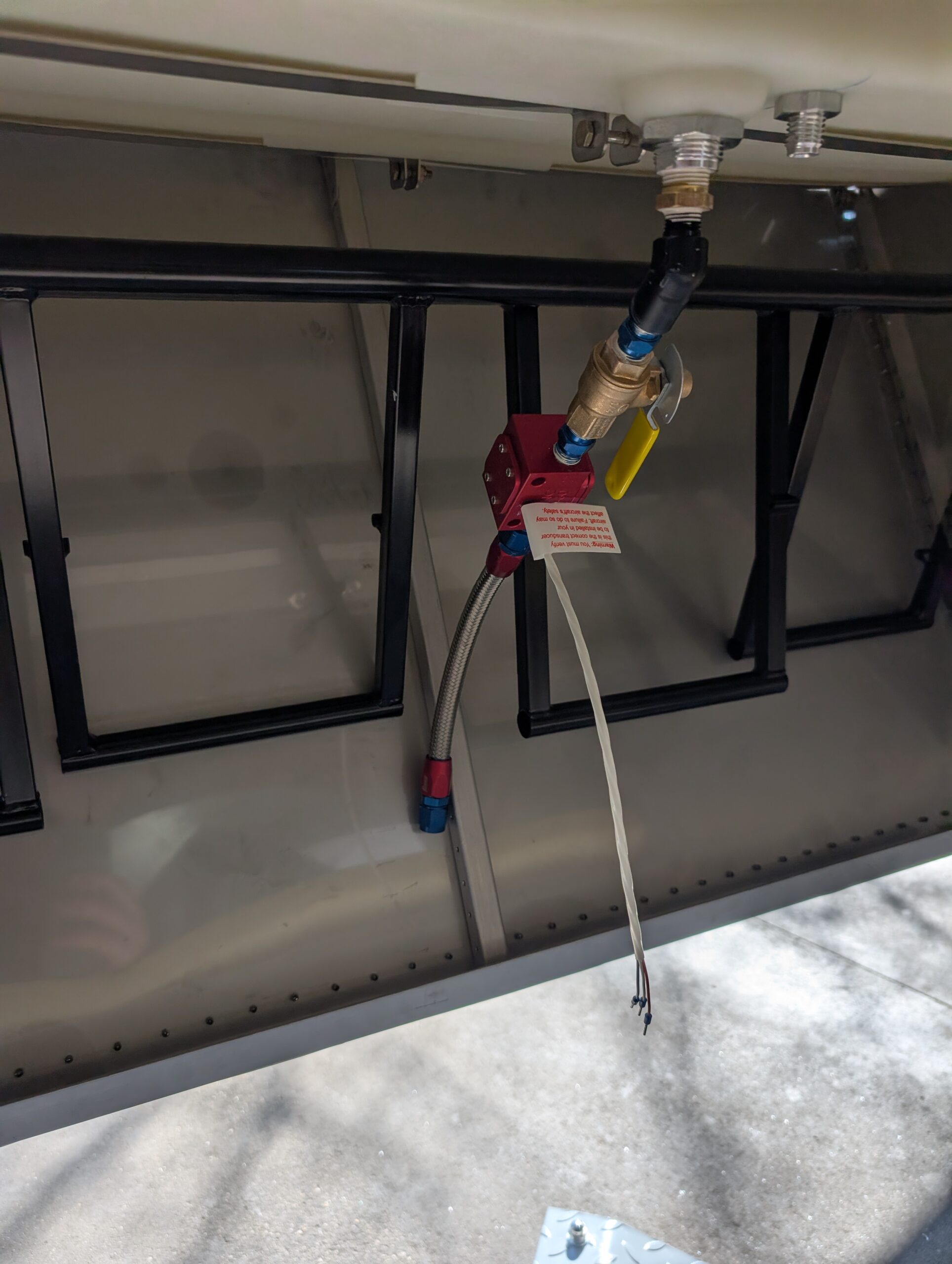

Fuel System Plumbing – Part 3

Installed 45 degree and AN fitting after fuel cube using Teflon paste. Cut a piece of solid aluminum fuel line to length and used tubing bender to bend into shape. Installed tube nut hardware on hardline and used flaring tool to flare ends of hardline. Installed hardline in between fuel flow cube and bulkhead fitting.…

-

Fuel System Plumbing – Part 2

Located new bulkhead hole one inch above plans measurement to ensure continuous fuel flow. Updrilled bulkhead hole to 9/16″. Created spacer from 1/8″ aluminum scrap to go between bulkhead tee fitting and nut to keep assembly from rotating. Tried to make flex hose to connect fuel system but couldn’t get the geometry correct due to…

-

Fuel System Plumbing – Part 1

Began plumbing the fuel system starting at the fuel tank. Used liquid teflon on all NPT threads. Made short run of fuel hose to go to bulkhead fitting. Had success creating fuel line by cutting line with cable snips and using zip tie around end to prevent jacket fraying. Marked firewall pass through location: will…

-

Fuel Tank Installation

Rinsed tank out with water to clear out debris from inside. Re-fit tank to fuselage and trimmed fuel bay area slightly more to accommodate vent fitting. Clecoed tank stop into place and confirmed tank was sitting full forward. Installed fuel tank straps and lightly tightened straps until they were touching the tank fully. Used AN3-7A…

-

Follow-up Storage Treatment #2

Performed long-term storage procedure IAW Jabiru Maintenance Manual. Removed plugs and lubricated cylinders with Phillips 20W50 Anti-Rust Oil. Reinstalled plugs but did not torque. Removed rocker covers and lubricated rocker chambers with same oil. Reinstalled rocker covers but did not torque. Pulled prop through 15 times.

-

Fuel Tank Prep – Part 2

Drilled hole in fuel tank for fuel vent “oops” fitting then deburred/cleaned. Temporarily installed fuel tank straps and fuel tank then marked location of fuel tank vent on glareshield with strap duplicator. Removed fuel tank and drilled slightly oversized clearance hole in glareshield. Rinsed tank thoroughly with water then installed temporary brass plugs in bottom…