Wing Root Doublers – Part 1

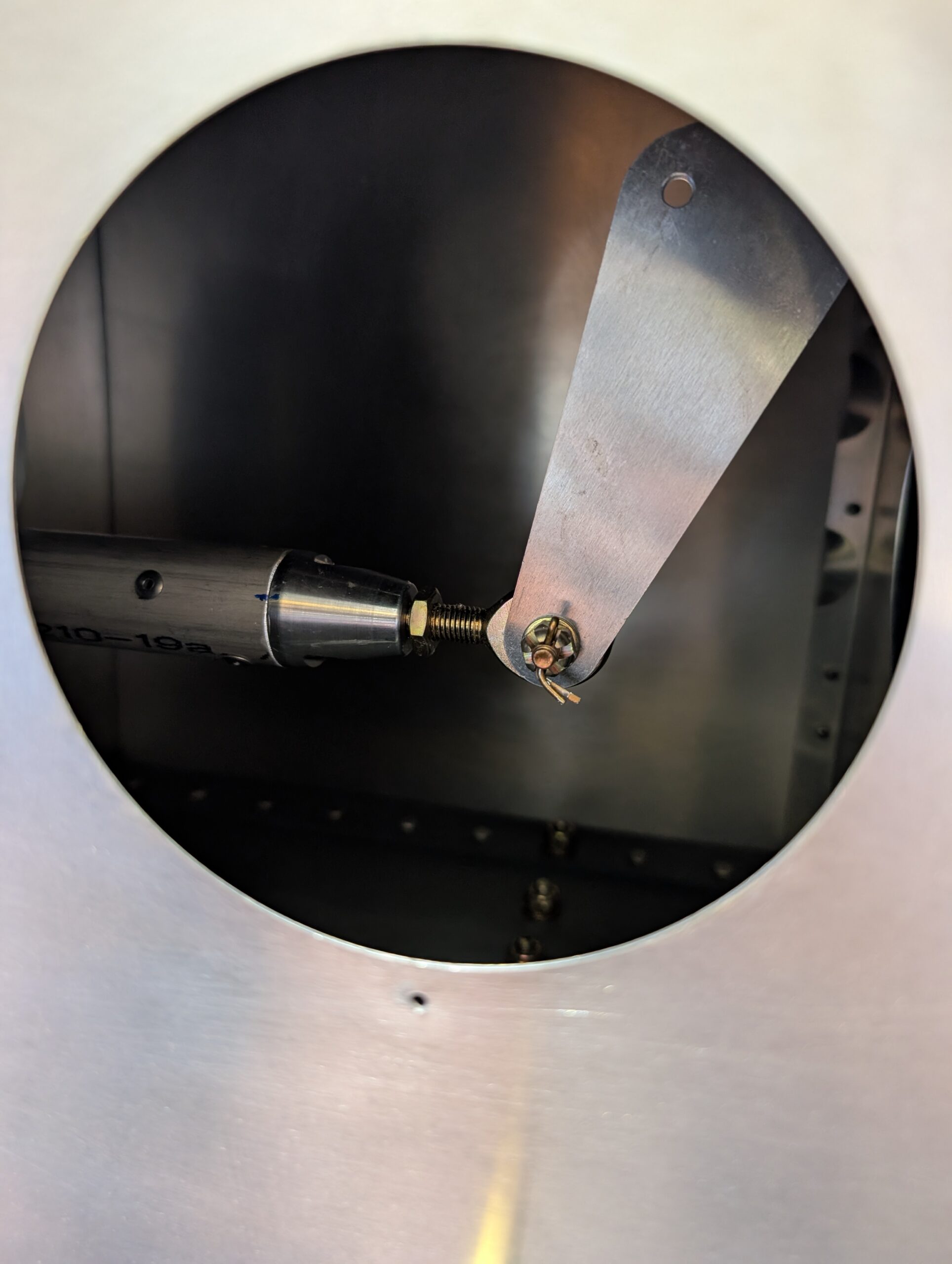

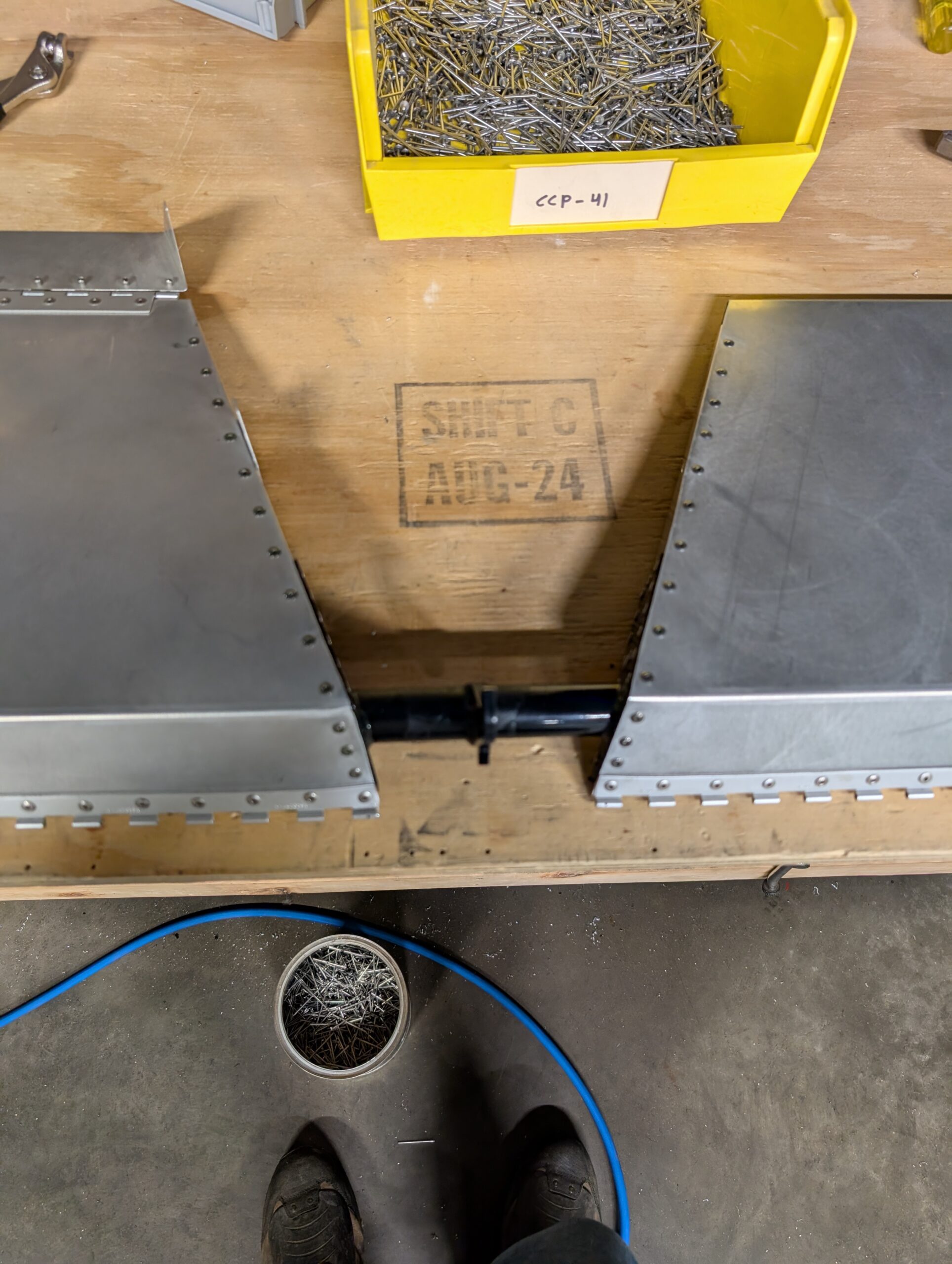

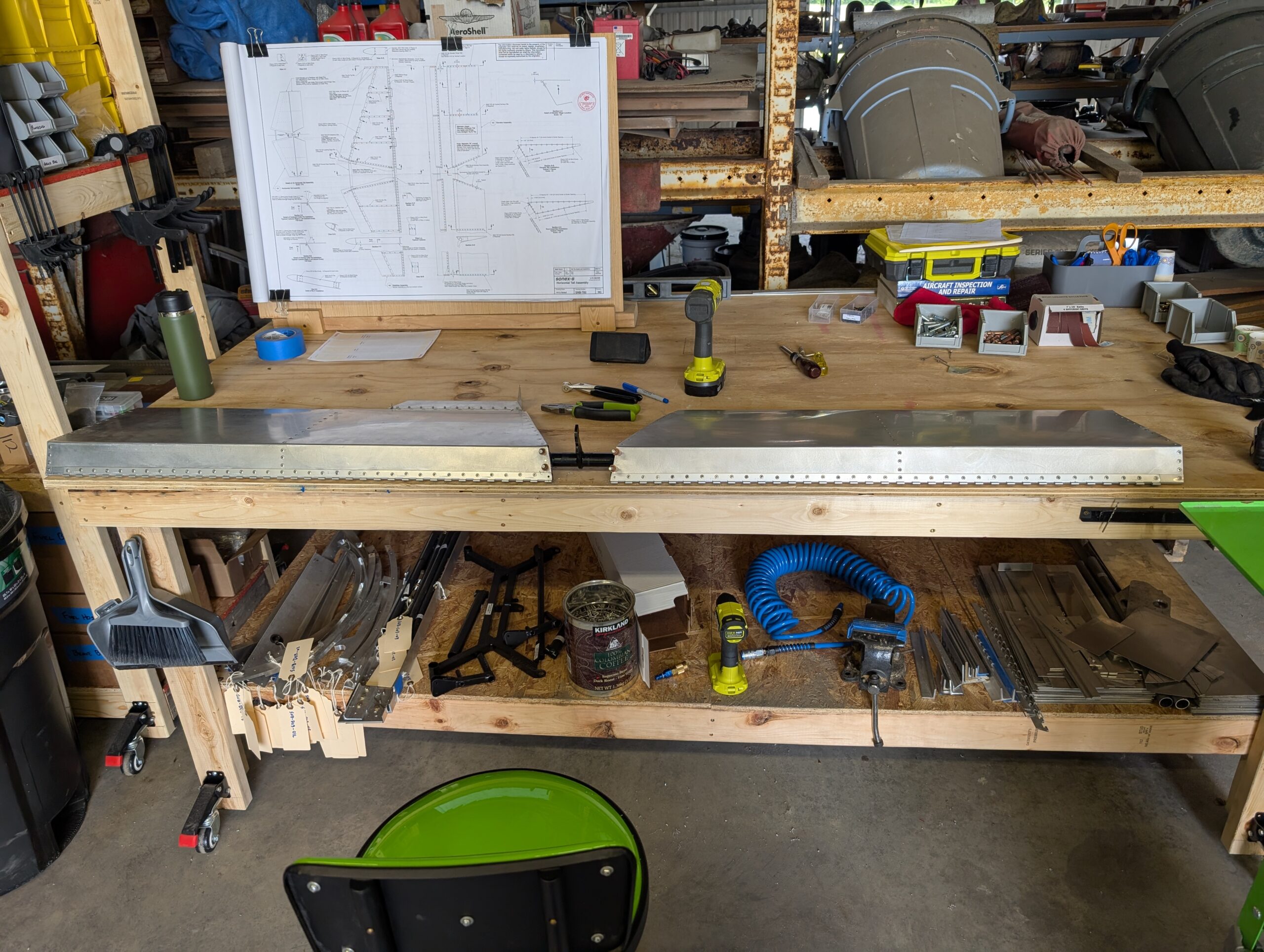

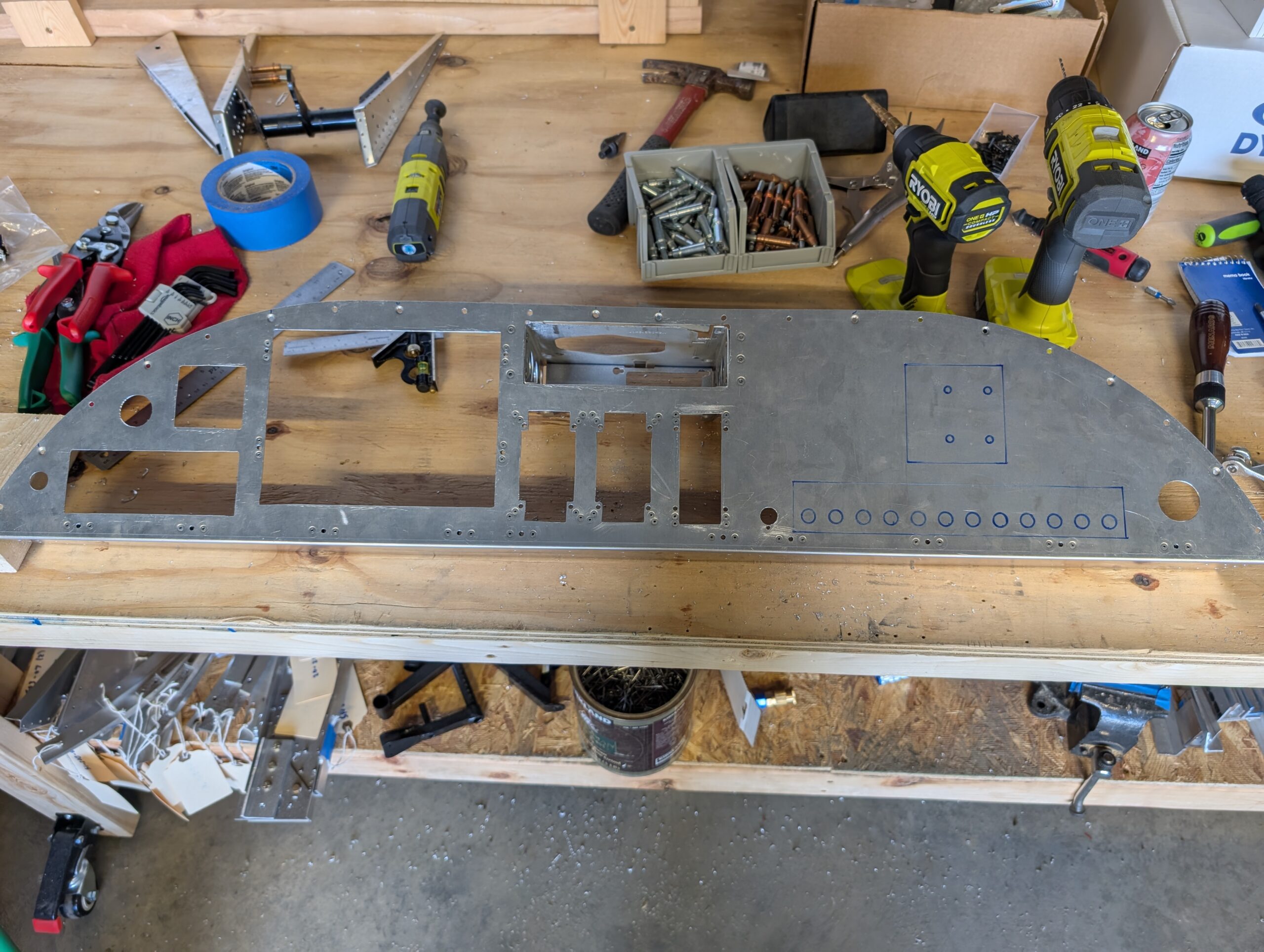

Slid wings out from fuselage (one at a time) and reinstalled wing root doublers with clecoes. Marked current edge of doublers onto wing skins with sharpie. Removed doublers then slid wings back into spar tunnel and pinned into proper place.…