Panel Installation – Part 3

Continued locating and installing nutplates into panel blank. Marked access hole locations on RH side of panel blank. Marked hole centers and began cutting out instrument holes into panel backer. Hours Worked: 2.57

Build Log for Sonex 0849B

Continued locating and installing nutplates into panel blank. Marked access hole locations on RH side of panel blank. Marked hole centers and began cutting out instrument holes into panel backer. Hours Worked: 2.57

Performed long-term storage procedure IAW Jabiru Maintenance Manual. Removed plugs and lubricated cylinders with Phillips 20W50 Anti-Rust Oil. Reinstalled plugs but did not torque. Removed rocker covers and lubricated rocker chambers with same oil. Reinstalled rocker covers but did not…

Continued prepping panel flange by dimpling right side flange and installing nut plates. Installed flanges back onto glareshield and checked fitment with panel and panel covers. Removed panel and covers and marked hole and cutout locations on panel. Cut a…

Began prepping panel for final riveting and installation by mocking up panel covers on panel backer. Fitment was just a little tight so filed away some material from inside edges of panel covers. Removed panel and flanges and dimpled every…

After some reflection on the slight shortcoming of up elevator travel, it was decided that the elevator horn should be removed and repositioned slightly forward to enable more up-travel. While the existing elevator horn will be retained the inboard elevator…

Mocked up ELT location on rear shear web and marked vertical stabilizer on where skin needs to be trimmed. Removed vertical stabilizer and marked out mounting hole location on shear web. Trimmed vertical stabilizer skin and riveted ELT mount and…

Mocked up vertical stabilizer into place and noticed elevator horn was impacting vertical stabilizer skin and preventing full motion. Removed vertical stabilizer and trimmed skin at base. Continued to file elevator horn to ensure full 25 degrees of pitch up.…

Began tail surface installation by moving tail surfaces from house to hangar. Discovered that horizontal stabilizer skins were installed upside down and that the bottom skins would need to be trimmed to fit around fuselage tail cone. Using the top…

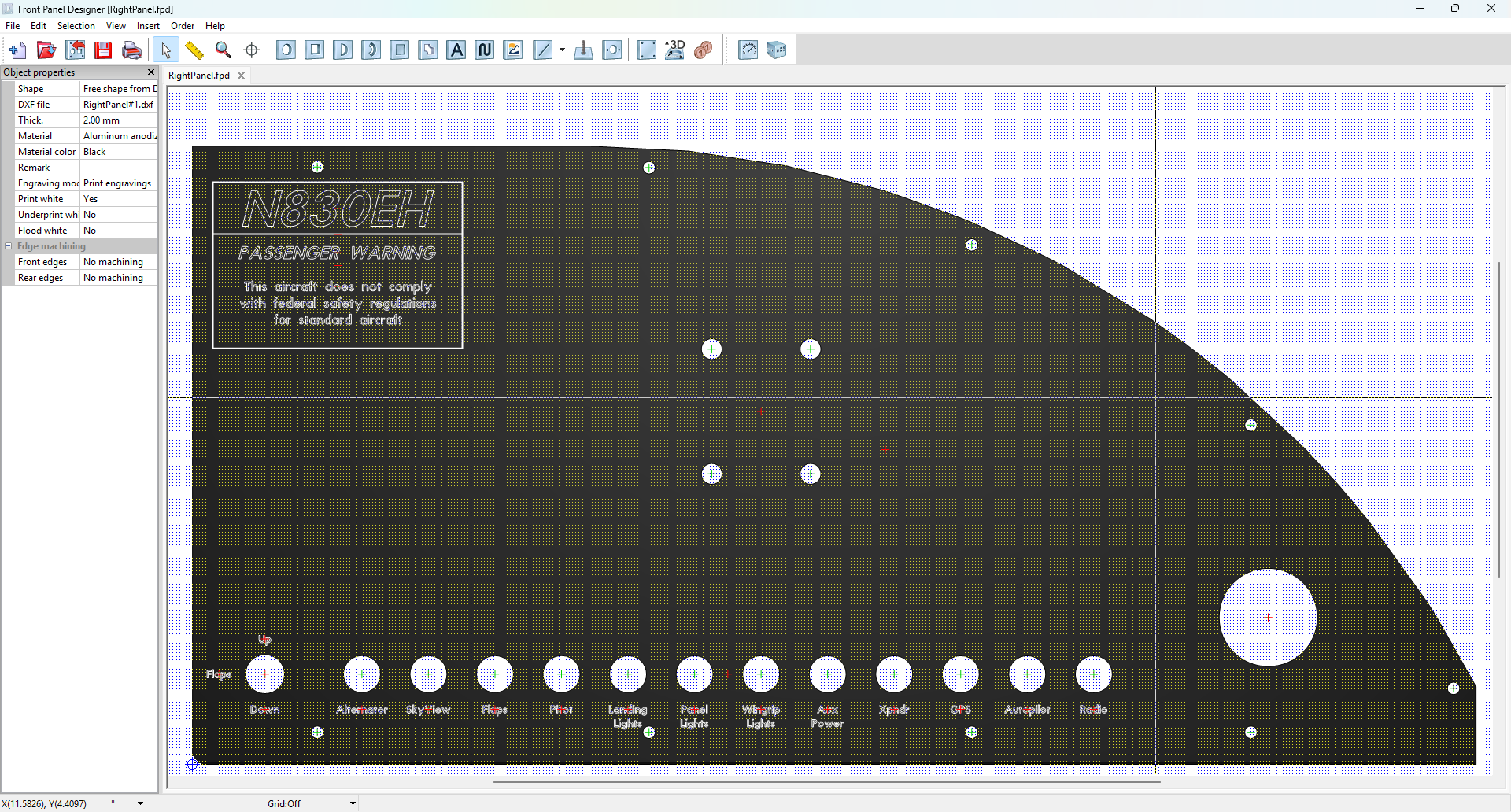

Exported panel files in Solid Works to DXF format to upload into Front Panel Designer. Imported files and began placing text on panels. Used Futura font and 10pt size in most places. Printed out front panel designs full scale and…

Cut aileron tube stock to size per plans for dual-stick configuration. Marked and drilled holes for pushrod end fittings, then deburred and riveted -01 main aileron pushrod assemblies. Pressed spoiler bearings into rod end bearings using vice then installed onto…

Installed 45 degree and AN fitting after fuel cube using Teflon paste. Cut a piece of solid aluminum fuel line to length and used tubing bender to bend into shape. Installed tube nut hardware on hardline and used flaring tool…